Catalog excerpts

High pressure safety filters

Open the catalog to page 1

Product range Suction lters Clogging indicators Ventilating lters Return lters Pressure lters Return-suction lters High pressure lters Return-suction lters Description ARGO-HYTOS produces sophisticated lter solutions together with hydraulic and lubrication systems. The range of solutions we have implemented extends from xed-position industrial plants to mobile applications. As well as customized developments, exactly adjusted to the individual requirements of the customer, ARGO-HYTOS offers a comprehensive range of innovative standard solutions for a wide variety of applications:...

Open the catalog to page 3

Product range Fluid and Motion Control Customized solutions Gear pumps Control solutions www.argo-hytos.com Subject to change · 0215

Open the catalog to page 4

Product range Fluid and Motion Control Directional and proportional valves Modular valves Sandwich valves Screw-in cartridge valves Slip-in cartridge valves Load motion cartridges Explosion proof valves Hydraulic power packs Description ARGO-HYTOS’ expertise in control technology is the fruit of more than 65 years‘ experience. We focus here on a wide range of valves, power units and integrated manifolds featuring all commonly used design features and functions, together with proportional valves and the associated control electronics: › Directly operated directional valves in CETOP 02 to...

Open the catalog to page 5

Product range Fluid Management Off-line lter Off-line lter Off-line lter unit Off-line lter unit Dewatering system Dewatering system Description As well as reducing maintenance and servicing costs, effective uid management is also a key factor in boosting the reliability, productivity and cost-effectiveness of the operation. ARGO-HYTOS supplies application-oriented products for manual and automatic cleaning of hydraulic uids: Off-line lters Off-line lter units Filter cooling systems Oil service units Dewatering systems www.argo-hytos.com Subject to change · 0215

Open the catalog to page 6

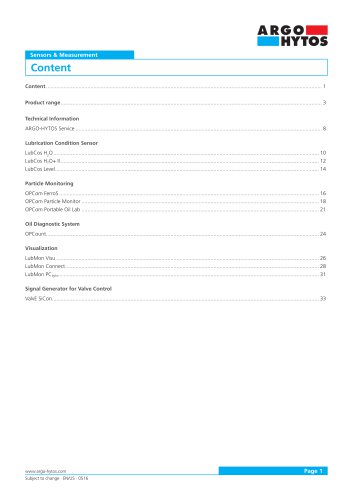

Product range Portable particle counter Portable oil lab Particle monitor Wear sensor Condition sensors Pressure sensor Remote interfaces / display units Valve electronics Systems that provide reliable assessment of the condition of hydraulic fluids are the key feature of continuous fluid Sensors and measurement technology from ARGO-HYTOS precisely target this range of tasks. Our fluid monitoring products comprise equipment and system solutions to enable online monitoring during continuous operation as well as analysis of bottled samples under laboratory conditions. > Portable oil diagnosis...

Open the catalog to page 7

www.argo-hytos.com Subject to change · 0215

Open the catalog to page 8

Filter Selection Guideline Tips and information on how to select the optimal hydraulic filter Preface When determining the required cleanliness in a hydraulic system, additionally to the technical requirements of the hydraulic components and to the operating pressure, the user‘s expectations to availibility, safety and service life of a machine become increasingly important. These aspects were particularly taken into account in the present ARGO-HYTOS guideline. Detailed attention is also given to two filter concepts which are becoming increasingly important: return-suction filters and...

Open the catalog to page 9

Our know-how - your benefit At ARGO-HYTOS, the focus is consistently on the customer – and a major element of our devel pment work is to implement o customer-specific solutions for filters and systems. Continuous improvement of our filter elements is another major o goal of our devel pment work: for example, this includes increasing the dirt capacity while keeping the installed volume as small as possible. This optimization goal is excellently achieved by our range of standard return-suction filters – just one example of many. r l Our sales engineers are just as eiable as our filters...

Open the catalog to page 10

Quality and safety The key feature of the entire hydraulics sector is that – for understandable reasons – users are setting demanding (and ever increasing) require ents for the quality and efficiency of the m filters that are used. The testing technology used to develop filters must also meet these requirements. And this is where the difference between “filters” and ARGO-HYTOS filters emerges very clearly! ARGO-HYTOS operates testing rigs that are equipped with ultra-modern technology, enabling fast test sequences, extended testing procedures and accurate documentation of all the...

Open the catalog to page 11

Mobile oil analysis The ARGO-HYTOS service vehicle Oil cleanliness requirements are becoming stricter as time goes on. Filters are now expected to offer service lifetimes of 1.000 hours or more. Oils that stay clean not only extend the usual intervals between oil changes – they also prevent faults during operation, and they substantially extend the lifetimes of all the hydraulic components. Only in rare instances do we know how clean or dirty the pressure fluid in a hydraulic system really is. In many cases, the medium is only examined when a failure occurs or when damage is noticed....

Open the catalog to page 12

Guideline on selecting the optimal hydraulic filter The ARGO-HYTOS procedure for selecting a filter The selection procedure described below makes it easy for you to select the right filters for hydraulic systems. To simplify matters, the procedure is broken down into these steps: Suction filters determine the right filter type determine the filter fineness that is needed determine the filter size that is needed other considerations This filter selection procedure is based on many years of practical experience with countless mobile and industrial hydraulic systems that are equipped with...

Open the catalog to page 13

How to determine the proper filter type Suction filters Hydraulic systems have to be fitted with a suction filter if there is a particularly high risk of damage to the pump from coarse contamination (Figure 1). Typical applications of this sort include: › systems with a common oil reservoir for working hydraulics and gear transmissions. › units with oil tanks of large dimensions and/or complex shapes, or those which are welded or casted. Experience shows that 100% cleaning of the tank prior to assembly is impossible under these circumstances. › systems that are filled under difficult...

Open the catalog to page 14All ARGO-HYTOS catalogs and technical brochures

-

MLS3-06

10 Pages

-

C5.3511 · C5.3516 · C5.3529

3 Pages

-

LS 040 · LS 075

6 Pages

-

ES 075

6 Pages

-

Catalogue Hydraulic Drives

65 Pages

-

Catalogue Fluid Management

69 Pages

-

Filtration Guideline

20 Pages

-

Light Line

4 Pages

-

Off-line Filtration

2 Pages

-

Catalogue Lightline

50 Pages

-

RC series

4 Pages

-

TS3 MTS2

6 Pages

-

TS4 MTS

6 Pages

-

ECOLINE

8 Pages

-

SR4P2-B2

4 Pages

-

SR1P2-A2

4 Pages

-

PRM7-10

10 Pages

-

PRM8-06

4 Pages

-

PRM2-04

20 Pages

-

PRM6-10

20 Pages

-

PRM7-06

10 Pages

-

PRM2-06

20 Pages

-

PRM7-04

10 Pages

-

Coils

18 Pages

-

Datasheet RPEL1-06

6 Pages

-

Datasheet RPH2-06

4 Pages

-

Datasheet RPR3-04

4 Pages

Archived catalogs

-

MDA Highlights 2015

24 Pages

-

Solutions for clean Oil

6 Pages

-

Brochure for Endusers

2 Pages

-

Agritechnica Highlights 2015

32 Pages

-

Brochure Wind Energy

2 Pages

-

EXAPOR MAX 2

3 Pages

-

Guidelines

21 Pages

-

Product summary

16 Pages

-

ARGO-HYTOS program summary

16 Pages