Website:

Arconic

Website:

Arconic

Group: Arconic

Catalog excerpts

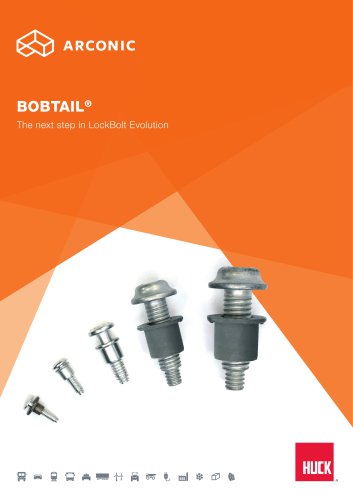

ARCONIC BOBTAIL® The next step in LockBolt Evolution

Open the catalog to page 1

BOBTAIL® NEXT STEP IN LOCKBOLT EVOLUTION The Huck BobTail system includes LockBolts and installation tooling that will deliver you benefits beyond anything that Arconic Fastening Systems & Rings Industrial Division has produced before. Key Benefits Cycle Installation Speed Speed of fastener installation has to be seen to be believed with the 1/4 diameter BobTail fastener installing in less than 1 second. The 16mm diameter BobTail fastener installs in 2 seconds, up to twice as fast as any large diameter LockBolt on the market. To see installation video visit www.afshuck.net Smooth, shock...

Open the catalog to page 2

Head Style: Round, Truss Head Material: Carbon Steel Other head styles and materials available on request.

Open the catalog to page 3

Head Style: Flanged Material: Carbon Steel Other head styles and materials available on request. Grip Range and Length Table Installed Dimensions Head and Collar Dimension Table

Open the catalog to page 4

Head Style: Round Material: Carbon Steel Other head styles and materials available on request. Installed Information and Max Hole Table

Open the catalog to page 5

Follow the form below to construct a part number for ordering BobTail pins and collars. Refer to the Grip Data chart for grip numbers. Small Diameter BobTail Pin (6,4 to 9,5mm) BT (HEAD STYLE) - (MATERIAL) (DIAMETER) - (GRIP NUMBER) (FINISH) Example: BT-R8-4GA is a BobTail LockBolt fastener, Round Head, Carbon Steel grade 5,8, 6,4mm (1/4”) Diameter, Grip 4 (3,2 to 9,5mm), Zinc Electroplate. Other collar types and materials available on request

Open the catalog to page 6

HUCK TOOLING SYSTEMS There are many different types of installation systems for the BobTail, dependent of fastener diameter, application type and application access. Some of the most popular tools are shown below but this is just part of our BobTail tooling range. Discuss your requirements with our dedicated systems team to find the optimum solution to suit your need. To install BobTail the basic tooling requirement is: H Installation Tool – Either pneumatic or hydraulic Nose Assembly – To match with the fastener and tool Powerig® – To supply power to hydraulic tools Additional Hose Set –...

Open the catalog to page 7

HOW IT WORKS How BobTail Works Installation Sequence Clamp Force or Pre–Load: In the initial stages of the installation process, the tool engages and pulls on the tail of the fastener. The joint is pulled together before the anvil portion of the nose assembly is forced down the collar. This progressively locks (swages) it into the grooves of the harder pin. The pin and swaged collar combine to form the installed fastener. The squeezing action reduces the diameter of the collar, increasing its length. This in turn stretches the pin, generating a clamp force over the joint. Shear strength of...

Open the catalog to page 8All Arconic catalogs and technical brochures

-

V964L Series

22 Pages

-

2812L Series Slam Latch

6 Pages

-

Green Energy Brochure

4 Pages

-

Magna-Bulb®

3 Pages

-

HuckForce Powerig™ Range

8 Pages

-

DIBt Newsletter

9 Pages

-

Torque Vs. Clamp

7 Pages

-

Huck 360 White Paper

5 Pages

-

Huck v. Time White Paper

4 Pages

-

Blind Fastener White Paper

5 Pages

-

Simmonds Nylstop DHE Series

2 Pages

-

Simmonds Nylstop MHT Series

2 Pages

-

Simmonds Nylstop PH Series

2 Pages

-

Simmonds Nylstop T Series

2 Pages

-

Simmonds Nylstop P Series

2 Pages

-

Simmonds Nylstop Series

3 Pages

-

Simmonds Cold Forging

2 Pages

-

Simmonds Product Brochure

2 Pages

-

Marson Threaded Inserts

7 Pages

-

Marson Value Rivets

4 Pages

-

Marson Product Brochure

44 Pages

-

SNEP Brochure

4 Pages

-

Recoil OEM

2 Pages

-

Recoil Kit for End User

2 Pages

-

Recoil Auto Aftermarket

2 Pages

-

Recoil product brochure

6 Pages

-

Camloc Handles CAM-D30

1 Pages

-

Camloc Handles CAM-D20

1 Pages

-

Camloc Handles CAM-D10

1 Pages

-

Camloc Hinges HC80

1 Pages

-

Camloc Hinges HC70

2 Pages

-

Camloc Hinges HC60

1 Pages

-

Camloc Hinges HC50

1 Pages

-

Camloc Hinges HC40

1 Pages

-

Camloc Hinges HC30

2 Pages

-

Camloc Hinges HC20

2 Pages

-

Camloc Hinges HC10

2 Pages

-

Camloc Hinges HI60

1 Pages

-

Camloc Hinges HI50

1 Pages

-

Camloc Hinges HI40

1 Pages

-

Camloc Hinges HI30

2 Pages

-

Camloc Hinges HI20

2 Pages

-

Camloc Hinges HS50

1 Pages

-

Camloc Hinges HS40

1 Pages

-

Camloc Hinges HS30

1 Pages

-

Camloc Hinges HS20

1 Pages

-

Camloc Hinges HS10

1 Pages

-

Camloc Locks CAM-L70

1 Pages

-

Camloc Locks CAM-L60

15 Pages

-

Camloc Locks CAM-L50

3 Pages

-

Camloc Locks CAM-L40

3 Pages

-

Camloc Locks CAM-L30

6 Pages

-

Camloc Locks CAM-L20

9 Pages

-

Camloc Locks CAM-L10

8 Pages

-

Camloc Locks, Hinges, Handles

75 Pages

-

Camloc Catalogue Keenserts

9 Pages

-

Camloc V18L Series

4 Pages

-

Camloc V917L Series

5 Pages

-

Camloc V951L Series

6 Pages

-

Camloc V96L Series

2 Pages

-

Camloc V95L Series

2 Pages

-

Camloc 1429L Series

5 Pages

-

Camloc CAM-PT10 Series

4 Pages

-

Camloc D4002 Series

10 Pages

-

Camloc Product Brochure

6 Pages

-

Camloc 715F Series

3 Pages

-

Camloc 991F Series

5 Pages

-

Camloc 2600-2700 Series

11 Pages

-

Camloc 50F Series (3700N)

6 Pages

-

Camloc 50F Series (900N)

6 Pages

-

Camloc 15F Series

3 Pages

-

Camloc 5F Series

4 Pages

-

Bobtail

2 Pages

-

Huck LockBolts

7 Pages

-

Magna-Lok®

10 Pages

-

FloorTight®

4 Pages

-

BOM®

4 Pages

-

Auto-Bulb?

2 Pages

-

Magna-Tite?

5 Pages

-

HuckLok?

2 Pages

-

Huck® LockBolts®

1 Pages

-

DIBt APPROVAL NEWSLETTER

6 Pages

-

244BT

22 Pages

-

255

2 Pages

-

245

2 Pages

-

241E

2 Pages

-

LH-224 Series

2 Pages

-

2025 Series

2 Pages

-

C6L®

14 Pages

-

The Huck® Product Range

7 Pages

Archived catalogs

-

HS7 Series (Huck-Spin Tool)

2 Pages

-

2480 Series

2 Pages

-

Hucktainer®

8 Pages

-

Hucktainer Encaps®

8 Pages

-

Magna-Grip®

10 Pages

-

C50L®

15 Pages

-

C120L®

18 Pages

-

BobTail®

2 Pages

-

FloorTight®

7 Pages

-

Auto-Bulb?

8 Pages