Website:

API Schmidt-Bretten, API Heat Transfer group

Website:

API Schmidt-Bretten, API Heat Transfer group

Group: API Heat Transfer

Catalog excerpts

SCHMIDT GASKETED PLATE HEAT EXCHANGERS ®

Open the catalog to page 1

Innovation, quality, and the experience of more than 140 years makes API Heat Transfer’s line of Schmidt® Plate Heat Exchangers an excellent choice for your heat transfer needs. Leadership in Plate Heat Exchangers Since 1879 The Schmidt® name traces its roots back to 1879 in Germany when the company founder, Wilhelm Schmidt, patented a new highly efficient counterflow external surface cooler for the brewing and dairy industries. The next major development was the first closed or pressurized spiral type plate heat exchanger constructed of brass plates milled with spiral channels and then...

Open the catalog to page 2

Automated Production API Heat Transfer’s commitment to meeting production demands is reflected by our continual improvement in manufacturing areas. Our unique plate pressing equipment takes the plate material from its raw state and converts it to a finished product in moments. Pressing tools are changed in minutes to allow easy conversion from one plate style to another. Special sensing equipment controls the pressure applied in the process to guarantee uniform thickness and the highest quality. Today & Tomorrow Today our Schmidt brand represents one of the widest selections of plate heat...

Open the catalog to page 3

Thermal Plate Options X SERIES HIGH PERFORMANCE PLATES Suitable for industrial and HVAC applications with clean, homogeneous, solid-free liquids. Thin film plates with corrugation depths between 2.0 and 3.0 mm for high thermal performance. Hard and soft plate corrugation patterns in the herringbone design to provide the most economic thermal solution for each application. Plates can be equipped with either the SIGMAFIX adhesive-free gasket system or with glued high performance gaskets. 7 SERIES UNIVERSAL PLATES Suitable for industrial, HVAC and liquid food applications. Hard and soft plate...

Open the catalog to page 4

Gasket Options SUPERIOR GASKET SEALING The sealing system used with our heat exchanger plates is designed as a one piece molded gasket with a vented double gasket boundary. This design prevents the two process fluids from mixing and gives you added peace of mind. If there are any leaks at the gasket around the plate or port areas, the leakage is to atmosphere and easily detectable. SIGMAFIX GASKET Our patented, adhesive-free gasket fastening system allows quick and easy gasket replacement through laterally built-in mounting clips. Ensures high resistance against front-face sticking and...

Open the catalog to page 5

Advantages – Features at a Glance Heat Transfer Performance The unique designs of our thermal plates produce high heat transfer coefficients for a given application, resulting in lower surface area and lower capital cost. Compact Design Plate heat exchangers contain large heat exchanging surfaces in a very compact, space-saving frame. This results in a much smaller space requirement and lower weight. Plates are formed in a wide variety of patterns and materials to meet your heat transfer needs. Peak Efficiency With high heat transfer coefficients and a true counter-current flow path, our...

Open the catalog to page 6

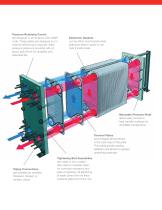

Pressure Retaining Covers are designed in accordance with ASME code. These plates are designed so no external reinforcing is required. Steel pressure plates are provided with an epoxy paint finish for durability and extended life. Elastomer Gaskets can be either mechanically fixed (adhesive-free) or glued to the heat transfer plate. Moveable Pressure Plate allows easy access to heat transfer surfaces for simplified maintenance. Thermal Plates have integral reinforcement in the neck area of the plate. This yields greater sealing reliability and allows for greater operating pressures. Piping...

Open the catalog to page 7

A world of heat transfer solutions API Heat Transfer’s global presence includes manufacturing facilities, R&D locations, and sales support throughout the world, all focused on one goal—to better serve our customers. Langenmorgen 4 75015 Bretten Germany 2777 Walden Avenue Buffalo, NY, 14225 USA API Heat Transfer 156 Qingqiu Street, 3rd District Suzhou Industrial Park Suzhou, Jiangsu 215126 China For more information about our heat transfer products, contact our API Heat Transfer sales representative or visit apiheattransfer.com or apiheattransfer.de GLOBAL HEADQUARTERS 2777 Walden Avenue |...

Open the catalog to page 8All API Schmidt-Bretten catalogs and technical brochures

-

SCHMIDT EVAPORATORS

10 Pages

-

OCA Series

6 Pages

-

SIGMASTAR

2 Pages

-

Steam Surface Condensers.

1 Pages

-

Basco® Type 500

1 Pages

-

SCHMIDT® SIGMASHELL

8 Pages

-

BOL Series

8 Pages

-

PCR With FinSep®

1 Pages

-

Gland steam condenser

1 Pages

-

Hairpin heat exchangers

1 Pages

-

SIGMA Plate Heat Exchangers

10 Pages

-

AOC Series

4 Pages

-

AOL Series

4 Pages

-

BOL Series

6 Pages

-

TTP Engine Cooling

8 Pages

-

Evaporators

8 Pages

-

SIGMASHELL

1 Pages

-

Basco Pipeline Aftercooler

8 Pages

-

Basco Type OP

8 Pages

-

Basco U-Tube

8 Pages

-

Basco/Whitlock Hub Design

16 Pages

-

Basco Type 500

12 Pages

Archived catalogs

-

EKT Series

2 Pages

-

BPCH Series

2 Pages

-

BPS Series

4 Pages

-

BP Series

20 Pages

-

EK Series

8 Pages

-

EC Series

6 Pages

-

CA Series

4 Pages

-

UC Series

5 Pages

-

DH Series

4 Pages

-

MA Series

4 Pages

-

OCA Series

28 Pages

-

AOC DC Fan Drive

4 Pages