Catalog excerpts

PALLET RACKING SOLUTIONS

Open the catalog to page 1

DESIGN, MANUFACTURE, INSTALL Based in Milton Keynes, Apex has provided pallet racking solutions to a huge number of household name brands, across all sectors and industries. Our leading design and technical solutions provide our clients with the best in storage solutions. ailmisei ailmiser

Open the catalog to page 2

CUSTOM DESIGN The best design for a business looking to implement a new storage solution, is the one that provides the ideal balance between capital cost, operational efficiencies (that improves ROI) and providing end user satisfaction. At Apex, we have been designing solutions with this in mind for more than over 75 years. We understand the importance of using the most appropriate storage equipment, utilising the cube to create maximum storage space, as well as minimising distances that products travel, increasing pick rates and improving pick accuracy. MANUFACTURED IN THE UK Maintaining...

Open the catalog to page 3

Apex maintains rigorous management processes in order to comply with a wide of policies, covering health & safety, environmental and quality. We operate quality systems in accordance with the latest ISO standards. Over the years SEMA has developed a series of relevant "Codes of Practice," which are the Industry standards. As SEMA Members, we are required to conform to these standards. ISO 9001:2008 Certification of quality management system for all areas of the business. ISO 14001 The globally recognised standard for environmental management. ound your horn BS OHSAS 18001-2007 The...

Open the catalog to page 4

Whittan is committed to Safety, Health, Environment and Quality Assurance. SHEQ is at the forefront of our business. We are fully aware of the responsibilities that come with working in a high risk industry, and as such, we constantly strive to continually improve our solutions that safeguard our staff, our customers, our supply chain and our planet. Our overall approach to efficiency, means that both customers and colleagues are able to make the safe choice. Our Safety, Health, Environment and Quality statements, along with our wider policies and procedures, allow us to maintain the...

Open the catalog to page 5

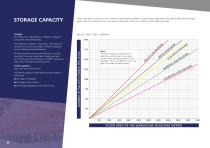

STORAGE CAPACITY These charts give an indication of the number of pallet positions available in a given space, depending on the type of pallet racking storage system used. This is based on the 2 most popular pallet sizes; 1200 entry x 1000 and 1200 x 800 entry pallet. Further guidance How many levels will there be? The following details will help determine the number of pallet levels: l The height of the pallet l The height of the building l The lift height/capability of the fork lift truck Note This chart includes an allowance for pedestrian access areas & cross-aisles, and are based upon...

Open the catalog to page 6

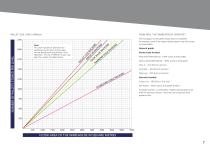

HOW WILL THE WAREHOUSE OPERATE? The throughput of the pallets should also be considered. For example, some of the higher density systems may limit access to stored pallets. NUMBER OF PALLETS STORED PER LEVEL Note This chart includes an allowance for pedestrian access areas & cross-aisles, and are based upon typical Reach Truck Operation. The use of different trucks may alter the number of pallets stored. General guide Mechanically Handled: Wide Aisle Pallet Racking - 100% access to every pallet Narrow Aisle Pallet Racking - 100% access to every pallet Drive In - FILO (First In Last Out)...

Open the catalog to page 7

WIDE AISLE The simplest of racking systems, wide aisle pallet racking allows direct access to every pallet and is easily adjustable, subject to manufacturers approval, to cater for different sizes and shapes of goods. Wide aisle (with a minimum of 2.5 metres wide aisles) requires no specialised handling equipment. A standard counter balance truck can be used in aisles 3.5 to 4 metres wide, whilst reach trucks can work in aisles only 2.5 metres wide. A limitation of using standard lift trucks, is that the racking systems height is restricted to the maximum lift height of the trucks. With...

Open the catalog to page 8

NARROW AISLE Narrow Aisle Racking significantly increases storage capacity compared, to Wide Aisle solutions, by reducing the aisle widths by up to 50% and increasing rack heights. This makes excellent use of the floor space and ensures maximum use of the available headroom, whilst still allowing individual access to all pallets stored. Specialist Narrow Aisle lift trucks are required in either ‘man-down’ or ‘man-up’ variants, allow movement in the narrow aisles. To reduce the risk of accidental damage from user error and to improve safety within the system, rails or wire guidance is...

Open the catalog to page 9

DYNAMIC STORAGE Our range of Dynamic Storage solutions can save up to 50% space and reduce travel distances by up to 80%. Pallet Live, Carton Live and Push-back Racking offer, maximum flexibility and efficiency in storing high turnover stock, with accurate FIFO or FILO flow of products. Pallet Live Racking First In - First Out (FIFO) Drive-in Racking is the ideal solution when space is at a premium, or high-density storage is required. By eliminating aisles, it is possible to maximise cubic space, enabling more pallets to be stored per cubic metre. Working on a first in, first out basis,...

Open the catalog to page 10

Push-Back Racking - First In - Last Out (FILO) Pallets are loaded and unloaded from the same aisle, reducing truck travel distances and improves workplace efficiency. Pallets are loaded in sequence onto roller beds or wheeled carriers and are pushed back along inclines to utilise the full depth of the racking. When a load is retrieved, the remaining pallets roll forward into position at the loading/unloading face. Ideal for utilising space against walls and for marshalling areas. Carton Live Storage - First In - First Out (FIFO) Working on the same principle as Pallet Live, Carton Live...

Open the catalog to page 11

MULTI TIER PALLET RACKING STRUCTURES Installing a multi tier pallet racking structure maximises your buildings storage capacity, without the need to extend or relocate. l Allows order picking on multiple levels Multi-tiers are most effective for online retailers and e-commerce operations where picking and packing are combined with a high SKU (Stock Keeping Unit) turnover. l Most efficient use of the building, maximising floor area against height The system is extremely cost-effective, as the racking structure supports the walkways - saving on construction costs. It improves the pick...

Open the catalog to page 12