Catalog excerpts

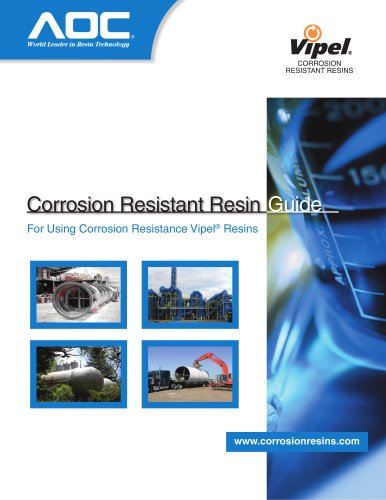

Vipel® Resin Overview AOC’s comprehensive family of Vipel® corrosion-resistant resins provides the optimum technology for long-term cost/performance in a wide range of corrosive environments. Resin Type Resin Series Higher styrene content version of Vipel F010. Good resistance to hot caustic solutions. Lower VOC/HAP and higher heat distortion temperature version of Vipel F010. Good balance of corrosion resistance and processability. User friendly in both filament winding and hand lay-up applications. Fire retardant, brominated bisphenol-A epoxy vinyl ester. Excellent resistance to both acidic and alkaline environments, plus thermal mechanical properties. Class I flame spread developed without synergists Fire retardant, brominated bisphenol-A epoxy vinyl ester. Lower in specific gravity than Vipel K026-AA. Excellent resistance to both acidic and alkaline environments, plus thermal mechanical properties. AOC is a leading producer of unsaturated polyester and vinyl ester resins and is the world leader in innovative resin technology. AOC manufactures its products in facilities strategically located throughout North America and Europe. AOC owned facilities are ISO 9001:2008 certified and use AOC’s proprietary process control technology to guarantee batch to batch consistency. From isophthalic polyesters, and terephthalics, to epoxy novolac and bisphenol A vinyl esters, AOC offers local availability, Class I flame spread developed without synergists worldwide, of a broad range of proven Vipel resins through its Fire retardant brominated bisphenol-A epoxy vinyl ester. Excellent resistance to both acidic and alkaline environments, plus thermal mechanical properties. network of distributors and plants. Please contact the AOC Class I flame spread with 1.5% antimony trioxide resistant specifications, and put the technology and service of Fire retardant, brominated bisphenol-A epoxy vinyl ester. Used in the structural layer where resistance to acidic and caustic environments are needed. Contains antimony products. the AOC Corrosion Team to work for you. Class I flame spread Fire retardant, bisphenol-A epoxy vinyl ester (higher cross-linked). Low VOC/HAP with excellent resistance to oxidizing chemicals at elevated temperatures. Class I flame spread developed without synergists Elastomeric Bisphenol A Epoxy Vinyl Ester Elastomeric bisphenol-A epoxy vinyl ester. For improved interlaminar adhesion and manufacturing composites that require extra flexibility. Epoxy Novolac Vinyl Esters Fire retardant, epoxy novolac vinyl ester. Recommended in pulp and paper industry for severe corrosion applications. Class I flame spread and smoke developed without synergists High molecular weight isophthalic/propylene glycol resin with broad chemical resistance at moderate temperatures and excellent processability. High molecular weight, two stage terephthalic, unsaturated polyester resin with the wet out, cure and handling characteristics of general purpose resins. F737 Terephthalic Polyester (High cross-linked) Excellent resistant to both acidic and alkaline environments. High monomer content and rigid. Isophthalic Polyesters CORROSIONRESINS.com The internet’s best resource on corrosion-resistant composites. Middle East Higher heat distortion temperature version of F085. Performs in a hotter environment. K095 Bisphenol A Fumerate Polyester Corrosion Specialists for Vipel resins that meet your corrosion Latin America Exceptional organic solvent resistance with improved high temperature properties. Sales Contacts North America Bisphenol A Epoxy Vinyl Esters Resilient isophthalic polyester. Designed for mild acidic environments. Meets UL 1316 and UL 1746 parts II and III and Steel Tank Institute requirements. AOC World Headquarters 955 Highway 57 East Collierville, TN 38017 +01 901 854 2800 +01 901 854 1183 (fax) corrosionresins@aoc-resins.com AOC and Vipel are registered trademarks of AOC, LLC. Printed in U.S.A. Copyright © February, 2012 AOC. Pub: AOCPowervs2012 Engineered Power and Energy Applications with Vipel technologies ®

Open the catalog to page 1

STACK LINER • • • • • Slurry Piping Slurry Strainers Wash Water Piping Baffles Mist Eliminator Beams Outlet Roof (Hood) Outlet Transition to Chimney Wash Water Piping Draw Off Piping Breaching Stack Liners Inside Chimney Stack Choke and Cap Corrosion Leadership CHIYODA CT-121 Jet Bubbling Reactor Slurry Piping Slurry Strainers Wash Water Piping Baffles Mist Eliminator Housing Structural Beams JBR Vessel (Shell, Floor, Roof) JBR Decks Gas Cooling Duct Gas Risers Oxi Air Piping Alignment Grid Columns Agitators Vipel® resin technologies are leading the fight against corrosion around the world....

Open the catalog to page 2

STACK LINER • • • • • Slurry Piping Slurry Strainers Wash Water Piping Baffles Mist Eliminator Beams Outlet Roof (Hood) Outlet Transition to Chimney Wash Water Piping Draw Off Piping Breaching Stack Liners Inside Chimney Stack Choke and Cap Corrosion Leadership CHIYODA CT-121 Jet Bubbling Reactor Slurry Piping Slurry Strainers Wash Water Piping Baffles Mist Eliminator Housing Structural Beams JBR Vessel (Shell, Floor, Roof) JBR Decks Gas Cooling Duct Gas Risers Oxi Air Piping Alignment Grid Columns Agitators Vipel® resin technologies are leading the fight against corrosion around the world....

Open the catalog to page 3

STACK LINER • • • • • Slurry Piping Slurry Strainers Wash Water Piping Baffles Mist Eliminator Beams Outlet Roof (Hood) Outlet Transition to Chimney Wash Water Piping Draw Off Piping Breaching Stack Liners Inside Chimney Stack Choke and Cap Corrosion Leadership CHIYODA CT-121 Jet Bubbling Reactor Slurry Piping Slurry Strainers Wash Water Piping Baffles Mist Eliminator Housing Structural Beams JBR Vessel (Shell, Floor, Roof) JBR Decks Gas Cooling Duct Gas Risers Oxi Air Piping Alignment Grid Columns Agitators Vipel® resin technologies are leading the fight against corrosion around the world....

Open the catalog to page 4

Vipel® Resin Overview AOC’s comprehensive family of Vipel® corrosion-resistant resins provides the optimum technology for long-term cost/performance in a wide range of corrosive environments. Resin Type Resin Series Higher styrene content version of Vipel F010. Good resistance to hot caustic solutions. Lower VOC/HAP and higher heat distortion temperature version of Vipel F010. Good balance of corrosion resistance and processability. User friendly in both filament winding and hand lay-up applications. Fire retardant, brominated bisphenol-A epoxy vinyl ester. Excellent resistance to both...

Open the catalog to page 5All AOC catalogs and technical brochures

-

AOC Crosslink, Volume 18

12 Pages

-

AOC Crosslink, Volume 19

12 Pages

-

Chroma-Tek Specialty Dispersions

13 Pages

-

AOC Resins Capabilities

8 Pages

-

Vibrin® Gel Coats

10 Pages

-

Resin Technology for CIPP

6 Pages

-

EcoTek® Sustainable Resins

4 Pages

-

Vipel® Resins for CIPP

8 Pages

-

CIPP RESINS

4 Pages

-

wind energy

6 Pages

-

AOC Crosslink

16 Pages

-

AOC Crosslink, Volume 16

16 Pages

-

Vipel® Guide to Fabricating

40 Pages

-

Atryl® Closed Mold Resins

4 Pages

-

Vipel® Resins for CIPP

8 Pages

-

Vipel® Vinyl Ester Brochure

6 Pages

-

Vibrin® Brochure

4 Pages

-

Hydropel® Brochure

4 Pages

-

Vipel® Corrosion Guide

32 Pages

-

AOC Capabilities Brochure

8 Pages