Website:

ANDRITZ AG

Website:

ANDRITZ AG

Group: ANDRITZ SEPARATION

Catalog excerpts

Krauss-Maffei disc and drum filters SSFE, TDF, TSF

Open the catalog to page 1

Krauss-Maffei disc and drum filters Table of contents Vacuum drum filter, TSF Process advantages, TSF Pressure drum filter, TDF Operation, TSF/TDF Technical data, TSF/TDF Vacuum disc filter, SSFE Operation, SSFE Technical data, SSFE Test centers Company profile Product lines Krauss-Maffei vacuum drum filters TSF Process advantages, SSFE

Open the catalog to page 2

Krauss-Maffei TSF vacuum drum filter Wide range of applications Drum filters are the most frequently used continuous rotary filters and are found in many different applications due to their simplicity and ease of operation. Applications include solid/liquid separation processes in the chemical industry, plastics production, mineral refining, food processing industry and in the field of environmental protection. To suit your specific requirements we provide our vacuum drum filter in gas-tight, press belt and wash belt design. Processing parameters Main applications Operation Continuous...

Open the catalog to page 3

Krauss-Maffei TSF vacuum drum filter Process advantages Krauss-Maffei TSF vacuum drum filter, 40 m², gas-tight Proven design Vacuum drum filter in gas-tight design Optimized sealing Krauss-Maffei vacuum drum filters are avail- Krauss-Maffei vacuum drum filters in gas- Further improved and maintenance-friendly able in various materials of construction and tight design are suitable for operating pres- sealing cover hood and trough. with special cake discharge systems. Con- sures up to 70 mbar overpressure. tinuous improvement and decades of experience enable us to best adapt our equipment to...

Open the catalog to page 4

Krauss-Maffei TDF pressure drum filter High-pressure filtration Krauss-Maffei TDF pressure drum filter, 16 m² Closed filter For fine and ultra fine-grained prod- Processing parameters ucts in particular, pressure filtration Operating principle Pressure filtration allows an increased specific filtration rate together with a higher product quality. With the closed design, toxic products can be processed under inert gas. When conventional methods are not sufficient, Krauss-Maffei pressure drum filters are the right choice for effective and reliable dewatering requirements. They operate at...

Open the catalog to page 5

Krauss-Maffei TSF/TDF drum filter Operation The suspension to be filtered is fed washed, dried by suction, and removed continuously to the filter trough. from the filter cloth. The washing liquid is Depending on the application, differ- applied to the cake either directly by wash- ent suspension distribution systems ing devices (weirs, spray nozzles) or through are available to guarantee optimum fil- a wash belt placed on top of the solids layer. tration properties. A special ANDRITZ KMPT-design pendulum Scraper discharge The filtrate from the wash zone can be agitator prevents...

Open the catalog to page 6

Krauss-Maffei TSF/TDF drum filter Technical data Filter type Filter Drum Drum Number A B C Weight Drive area diamter width of cells ■ All data referring to TSF design. *) also available in TDF design. ■ Dimensions of TSF gastight and TDF on request. ■ Operating weight of filter includes through filling (app. data). ■ Power requirements in kW for drum drive and pendulum agitator drive (excl. vacuum and filtrate pump). All technical data are approximate and subject to change without notice.

Open the catalog to page 7

Krauss-Maffei SSFE vacuum disc filter High-capacity filtration High yield and product quality, combined with low production costs and environmental protection, provide the producer of bulk materials with a decisive competitive edge. A reliable process technology like filtration is an essential characteristic. The Krauss-Maffei disc filters, based on many years of experience and countless applications, give you an efficient filter operation to provide these attributes. These filters boast a tried-and-tested technology – and one that you can rely on day after day. Krauss-Maffei vacuum disc...

Open the catalog to page 8

Krauss-Maffei SSFE vacuum disc filter Process advantages Individual piping of cells Solids discharge Krauss-Maffei disc filters offer up to 80% more throughput and only 40% specific energy consumption com- pared to conventional disc filters. You benefit from high filtration performance, improved product qualities, and simple ■ Several filter cells with small cell volume ■ Short filtrate pipes with large hydraulic flow surface. Individual piping for each compartment. ■ High immersion depth. ■ Enlarged suction zone. ■ Single trough design. Your benefits: ■ Large filter area per disc. ■...

Open the catalog to page 9

Krauss-Maffei SSFE vacuum disc filter Operation Suspension feed Filtrate discharge Solids discharge The suspension is fed continuously into the All cells are provided with a separate filtrate As the disc filter rotates, the cake is dried by separate troughs and flows in the same di- pipe ending in the sealing plate. The filtrate removing the liquid and is discharged from rection as the rotating filter discs. Each filter flows along the control valve face and the the cloth at the end of this zone by means disc is divided into 30 cells. They rotate at control valve head to the receiver which...

Open the catalog to page 10

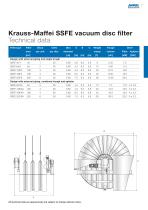

Krauss-Maffei SSFE vacuum disc filter Technical data Filter type Design with external piping and single trough SSFE 42/1 Design with external piping, combined trough and agitator SSFE 84/2A A All technical data are approximate and subject to change without notice.

Open the catalog to page 11

ANDRITZ KMPT Test centers Test center in Vierkirchen, Germany Production works in Florence, USA Based on these tests, we will provide equipped test centers in Germany a complete report which will recommend and the USA, offering both bench and the best solution for your solid/liquid sepa- pilot scale equipment. ration process, including scale-up informa- Our experienced engineers will consult with tion for the production equipment. you to determine the equipment most appropriate for your product, then will per- We can also assist in running long-term tri- form the necessary trials to...

Open the catalog to page 12

ANDRITZ KMPT Services Refurbished equipment Spare parts Our goal is to provide our customers with fast and reliable service, from the Our service centers are ready to provide you You can reach our skilled and experienced first process consultation throughout with regularly scheduled maintenance or service team around the clock. the entire service life of your ANDRITZ emergency service at your site. Our experts KMPT process equipment. provide assistance including assembly Maintenance contracts To assist our global customer base, we op- work, installation support, commissioning, We offer you...

Open the catalog to page 13All ANDRITZ AG catalogs and technical brochures

-

ANDRITZ BELT PRESS CPF-Q

12 Pages

-

GOUDA DRUM DRYER

32 Pages

-

TURBO GENERATOR SERVICE

8 Pages

-

TURBO GENERATORS

12 Pages

-

Image brochure

15 Pages

-

ANDRITZ METALS presentation

26 Pages

-

ANDRITZ SeaSOx brochure

9 Pages

-

ANDRITZ Maerz brochure

11 Pages

-

ANDRITZ belt press

8 Pages

-

Mill sifter

4 Pages

-

Yeast drying

4 Pages

-

PUREVO - the pharma centrifuge

20 Pages

-

Hydrasand

8 Pages

-

Lattomattic

2 Pages

-

Pump solutions for mining

5 Pages

-

Belt Drying System BDC

2 Pages

-

Mining & Minerals

9 Pages

-

F-type decanter centrifuge

4 Pages

-

Torrefaction of biomass

2 Pages

-

Solid bowl decanter D

4 Pages

-

Solid bowl decanter A

3 Pages

-

Power press belt filter

2 Pages

-

Aquaguard

2 Pages

-

Girapac

2 Pages

-

Aqua Screen

2 Pages

-

Aquadrum

2 Pages

-

Air pollution control

13 Pages

-

Aquatic feed

6 Pages