Catalog excerpts

RECTANGULAR LIFTING ELECTROMAGNET APPLICATION AREA RTAs are rectangular three-pole electromagnets with an aluminium winding. They are recommended for handling products with a flat surface: - slabs, - ingots, - metal sheets, - beds of extruded section. Their robustness means they are ideal for intensive use in areas such as : - continuous casting, - hot and cold rolling mills, - flame cutting workshops, - steel distribution networks, - shipyards. TECHNICAL DESCRIPTION RTAs consist of a precision-welded steel frame protecting the winding. The main component parts are : - a three-pole magnetic circuit made of high magnetic permeability steel. The mechanical fittings and contact surfaces are machined, - Two double suspension lugs with bolts and washers for a joint-ring two-strand chain, - a concentric aluminium winding with reinforced insulation, - a wear plate made of non-magnetic manganese-silicon steel. This highstrength part is welded to the frame, - filler resin protecting and holding and insulating the winding in the frame (class H or C depending on the application), - a compartmented double electrical box enabling external connections while protecting the internal winding. Standard RTAs can easily be modified to allow special applications : - 4 suspension lugs, - lateral handling hooks, - orientation or tipping clevises, - immersion chambers. Used on their own, they are suspended using a joint-ring two-strand chain. For longer products, several RTAs can be assembled on fixed or telescopic sling bars. The electrical connection is ensured by a 3-conductor large-cross section cable protected externally. SPECIFICATIONS The performance varies according to various parameters : - characteristics of the ferromagnetic parts to be lifted, - temperature of the products (up to 650° C), - thickness of the load, - air gap between the magnet and the load. The influence of the air gap and of the load’s thickness on the lifting capacity is detailed in the graphs in appendix. INSTALLATION PROCEDURE Six types of RTA are proposed according RTAs can be installed on any lifting sys- to their width : tem (overhead crane, crane, gantry, sta- 300, 400, 500, 600, 700, 800 mm. THE PLUSES cker). - Welded steel frame extremely resistant to impacts and wear, - Protection of the magnetic circuit against external particles and humidity, - Light weight thanks to the use of aluminium, - Double connection box. UTILISATION INSTRUCTIONS No specific maintenance or servicing required except a periodic check of the electrical connections, the suspension links and the frame

Open the catalog to page 1

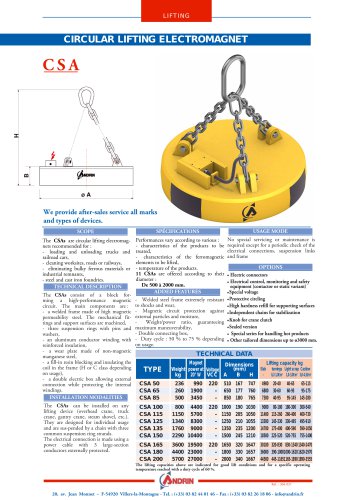

TECHNICAL FEATURES We provide after-sales support for all makes and types of equipment. OPTIONS • Temperature probe • Electrical connectors • Electrical control, monitoring and safety equipment (contactor or static variant) • Specific voltage • Protection hooping • Pole extension • Hard facing of the contact faces • Independent chains for stabilisation • Bushed lugs • Four-lug suspension • Watertight version • Cast frame version • Special HV series for handling hot products up to 650°C • Other made-to-measure dimensions • Fixed and telescopic sling bars

Open the catalog to page 2

PERFORMANCE GRAPHS (LIFTING FORCES) FOR E24 GRADE STEEL Per NFC 79-300 (44-4-1) standards The lifting capacities above are given for good gripping conditions. They are the average of five lifting operations for a running temperature that has been reached with a duty cycle of 60%.

Open the catalog to page 3

PERFORMANCE GRAPHS (LIFTING FORCES) FOR E24 GRADE STEEL Per NFC 79-300 (44-4-1) standards The RTA-series electromagnets are grouped according to their widths: 30, 40, 50, 60, 70 and 80. There is a graph for each width making it possible to determine, for each electromagnet, the separation force (see NF C 79-300, 44.4.1.1. Operating check of lifting electromagnets) according to the following data: thickness of the flat load made of E24 steel (E), air gap (e) and part of the pole surface covered by the load. The graphs show the separation forces in daN for each decimetre of length of the...

Open the catalog to page 4