Catalog excerpts

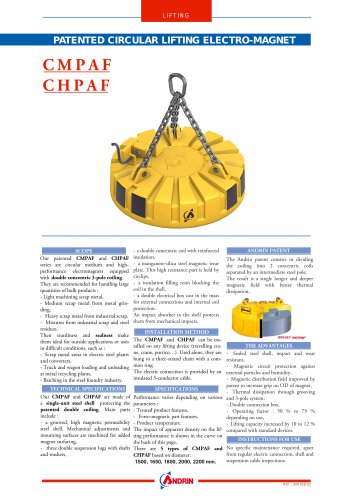

PATENTED CIRCULAR LIFTING ELECTRO-MAGNET CMPAF CHPAF SCOPE Our patented CMPAF and CHPAF series are circular medium and highperformance electromagnets equipped with double concentric 3-pole coiling. They are recommended for handling large quantities of bulk products : - Light machining scrap metal, - Medium scrap metal from metal grinding, - Heavy scrap metal from industrial scrap, - Mixtures from industrial scrap and steel residues. Their sturdiness and sealness make them ideal for outside applications or uses in difficult conditions, such as : - Scrap metal areas in electric steel plants and converters, - Truck and wagon loading and unloading at metal recycling plants, - Batching in the steel foundry industry. TECHNICAL SPECIFICATIONS Our CMPAF and CHPAF are made of a single-unit steel shell protecting the patented double coiling. Main parts include : - a grooved, high magnetic permeability steel shell. Mechanical adjustments and mounting surfaces are machined for added magnet surfacing, - three double suspension lugs with shafts and washers, - a double concentric coil with reinforced insulation, - a manganese-silica steel magnetic wear plate. This high resistance part is held by circlips, - a insulation filling resin blocking the coil in the shell, - a double electrical box cast in the mass for external connections and internal coil protection. An impact absorber in the shell protects them from mechanical impacts. ANDRIN PATENT The Andrin patent consists in dividing the coiling into 2 concentric coils separated by an intermediate steel pole. The result is a single longer and deeper magnetic field with better thermal dissipation. INSTALLATION METHOD The CMPAF and CHPAF can be installed on any lifting device (travelling crane, crane, portico…). Used alone, they are hung to a three-strand chain with a common ring. The electric connection is provided by an insulated 3-conductor cable. THE ADVANTAGES - Sealed steel shell, impact and wear resistant, - Magnetic circuit protection against external particles and humidity, - Magnetic distribution field improved by patent to increase grip on OD of magnet, SPECIFICATIONS - Thermal dissipation through grooving Performance varies depending on various and 3-pole system, parameters : - Double connection box, - Treated product features, - Operating factor : 50 % to 75 % - Ferro-magnetic part features, depending on use, - Product temperature. - Lifting capacity increased by 10 to 12 % The impact of apparent density on the lif- compared with standard devices. ting performance is shown in the curve on INSTRUCTIONS FOR USE the back of this page. There are 5 types of CMPAF and No specific maintenance required, apart from regular electric connection, shell and CHPAF based on diameter: suspension cable inspections. 1500, 1650, 1800, 2000, 2200 mm.

Open the catalog to page 1

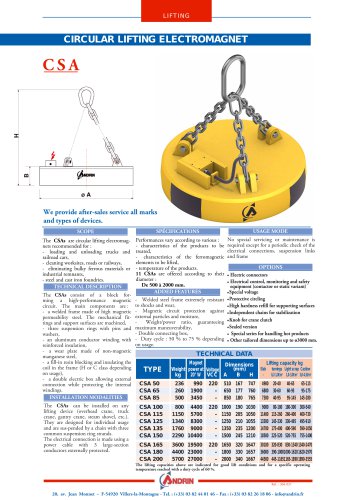

TECHNICAL FEATURES C MPAF – CHPAF We provide after-sales service all marks and types of devices. patented Andrin Magnet Weight strength at VDC kg 20 kW voltage Lifting capacity in kg Size (mm) A B Slab Socket Chip Light scrap Pig mould - Cast iron scrap 0.2-1.0 t/m3 1.0-3.0 t/m3 3.0-4.5 t/m3 The lifting capacities above are indicated in good holding conditions and at temperatures achieved with a percentage duty cycle of 60 %. OPTIONS • Electric devices • Electrical control, monitoring and security equipment (contactor or static variant) • Specific voltage • High-hardness mounting surface...

Open the catalog to page 2

AVERAGE LIFTING CAPACITY GRAPH BASED ON BULK MATERIAL DENSITY Standards: NFC 79-300 (44-4-2) Density : tons/m3 The lifting capacities above are indicated in good holding conditions. They are the average of 5 lifts at a temperatures achieved with a percentage duty cycle of 60 %. Réf. : 304 129 02

Open the catalog to page 3

AVERAGE LIFTING CAPACITY GRAPH BASED ON BULK MATERIAL DENSITY Standards: NFC 79-300 (44-4-2) The lifting capacities above are indicated in good holding conditions. They are the average of 5 lifts at a temperatures achieved with a percentage duty cycle of 60 %. Andrin S.A. - RCS Briey B 645 510 355 - The information is given for information purposes only and is subject to change - Non-contractual document - 06/2005 • MSC

Open the catalog to page 4