Catalog excerpts

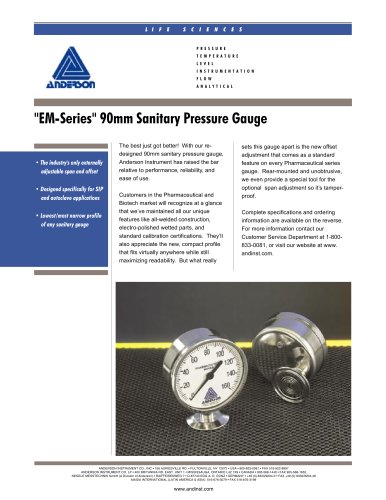

The 90mm Anderson "Pharmaceutical" gauge has rapidly become the pressure gauge of choice for applications in the pharmaceutical and biotechnology industries. It is designedto meet the most stringent of speci cations, including thosefor accuracy, surface nish, and temperature stability.Applications include process lines and vessels, ltrationequipment, pumps, heat exchangers and other pressure dependent devices or processes. These gauges are particu- larly appropriate when the process line or equipment will be steam sterilized. The un lled version can even be completely autoclaved while on the equipment.A few of the unique features of this gauge include the electropolished diaphragm and standard re-zero feature, along with a special polysulfone crystal that withstandsautoclave temperatures as well as cleaning chemicals that readily etch other lenses. Each gauge is shipped with a cer- ti cate of calibration, your assurance that it has beencalibrated to the most exacting tolerances.A new available option provides increased dampening,without oil- lling the case.For complete peace of mind in specifying sanitary pressure gauges that meet or exceed the CGMP's of the Pharmaceuti-cal Industry, specify the Anderson "Pharmaceutical Series". CONSTRUCTION/FINISH Diaphragm: Welded 316L stainless steel, electropolished. Maximum R > PERFORMANCE Calibrated Accuracy: 0.75% of full scale, from 10% - 90% of range (pressure ranges) ѱ 0.75% of full scale, from 25" vacuum to 90% of pressure range (compound ranges) Repeatability: 0.25% of full scaleHysteresis: ѱ 0.25% of full scaleLinearity: 0.25% of full scaleOperating Temperature Limits (process): 25 to 250ѰF (-3 to 124C)Ambient Temperature Limits: 40 to 120аF (4 to 49C)In-line Steam Sterilization Limits: Up to 300аF (149C) for 1 hour Autoclave Sterilization Limits: Up to 300аF (149C) for 1 hour (un lled case only)Temperature Effect: б 0.16% /10F change in process or ambient temperatureStability: Within speci ed accuracy for 6 months under normal operating conditions. Calibration check recommended at 3 month intervals for gauges being steam sterilized or autoclavedOver-range Capability: 10% of span > a = 8 microinches (.2 microns)Fitting: Welded 316L stainless steel polished (180 grit)Case and Stem: Welded 304 stainless steel polished (180 grit)Crystal: Polysulfone, .080" minimum thickness, corrosion resistantDial: 3.50 inch diameter (90 mm); pressure sensitive adhesive Standards: Designed and manufactured to sound engineering practices in accordance with Article 3.3 of the PED 97/23/ECEnvironmental Rating: NEMA 4X, IP-66 OPERATIONAL Capillary (internal) Fill: 80% glycerine (food grade) / 20% USP de-ionized waterRe-zero Feature (standard): Tamper-resistant; б 5% of span, non-interactive with spanResponse Characteristics (Typical): Un lled: 40% (Gauge dampens 40% of pulsation) Filled: 45% Mechanically Dampened: 95% > M E E T S O R E X C E E D S C G M P ' S O F T H E P H A R M A C E U T I C A L I N D U S T R Y size="-1">

Open the catalog to page 1

DIAL NAME/LOGO 01 Anderson MOUNTING CASE FILL 1 Bottom 4 Back 5 Left 6 Right 0 Un lled Case 2 Mechanical Dampening PROCESS CONNECTION 004 1-1/2" Tri-Clamp 005 2" Tri-Clamp 016 1-1/2" C.B. "I" Line (male) 017 2" C.B. "I" Line (male) 123 Anderson "CPM" Flushmount CAPILLARY FILL 1 Mineral Oil 4 80/20 Glycerin/H > ANDERSON INSTRUMENT CO., INC. 156 Auriesville RoadFultonville, NY 12072 USA1-800-833-0081 FAX 518-922-8997 PRESSURE RANGE > ANDERSON INSTRUMENT CO. LP 029 30" Hg/0/30 psig (-1/0/2 Bar) 031 30" Hg/0/ 60 psig (-1/0/4 Bar) 032 30" Hg/0/100 psig (-1/0/7 Bar) 033 30" Hg/0/160 psig (-1/0/11...

Open the catalog to page 2All Anderson Instrument catalogs and technical brochures

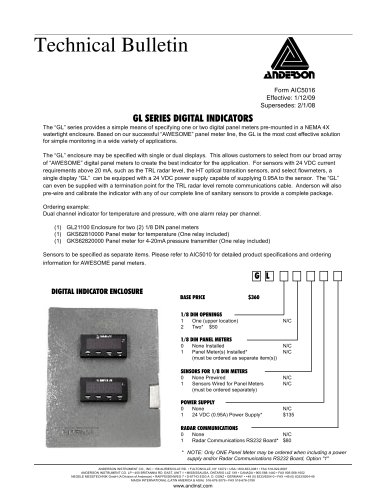

-

LA

2 Pages

-

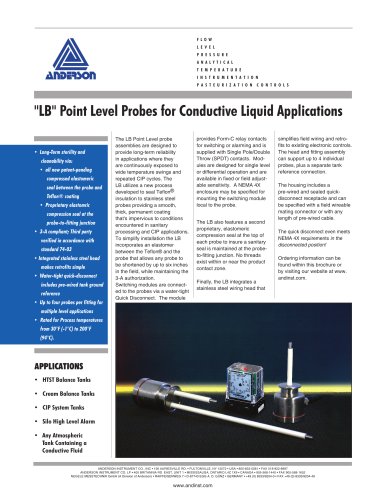

LB/LL

4 Pages

-

TD

4 Pages

-

SL

4 Pages

-

Turbine Flowmeter

2 Pages

-

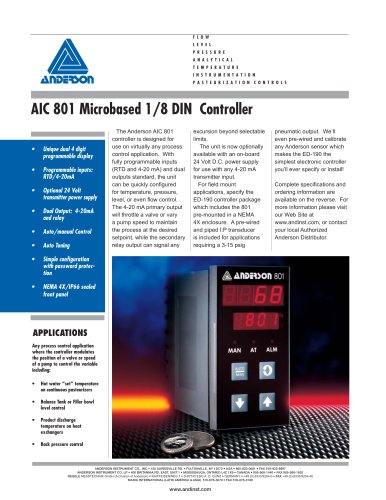

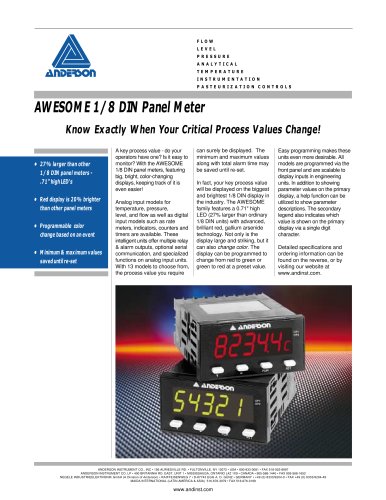

AWESOME 1/8 DIN Panel Meters

2 Pages

-

Thermowells

2 Pages