Catalog excerpts

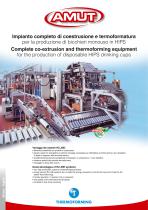

Impianto completo di coestrusione e termoformatura per la produzione di bicchieri monouso in HIPS Complete co-extrusion and thermoforming equipment for the production of disposable HIPS drinking cups Vantaggi dei sistemi IN LINE: • altissime produttività per prodotti a basso peso; • elevato risparmio energetico (si elimina l’energia necessaria per raffreddare a bobina prima e poi riscaldare la foglia in ingresso alla termoformatura); • operatività del personale semplicata (necessario, in produzione, 1 solo addetto); • massima qualità del prodotto termoformato; • riciclaggio in linea dello scarto. Italiano - English Great advantages of IN LINE systems: • very high production output for extremely light products; • energy saving (IN LINE systems do not need the energy required to cool the foil reel and to heat the foil before thermoforming); • friendly operation (1 operator only is required); • best quality of the thermoformed products; • complete in line scrap recycling.

Open the catalog to page 1

Principali caratteristiche tecniche Main technical features • Extrusion section for the production of multilayer sheet up to 4 layers, to thermoform two-coloured cups for vending machines. • Special calendering for the in-line thermal conditioning of the extruded sheet, with servo drives for the electric synchronization with the index of sheet. • Forming station, with servo drive. • Plugs device, with servo drive. • Horizontal punching, with servo drives for the electric synchronization of all movements. • Grinding units for the in-line, total reclaiming of scraps (skeleton and thermoformed...

Open the catalog to page 2All AMUT catalogs and technical brochures

-

TURBO WASHER

2 Pages

-

PET RECYCLING AT 500 KG

2 Pages

-

SUPERCENTRIFUGE

2 Pages

-

FRICTION WASHER

2 Pages

-

PET BOTTLE WASHING LINES

12 Pages

-

Pipe in Pipe

4 Pages

-

CROSS-HEADS

2 Pages

-

TEX & TEPO series

4 Pages

-

TEAT series

4 Pages

-

CAST FILM LINES

8 Pages

-

Conical Twin Screw Extruders

4 Pages

-

BOTTLE-TO-PACKAGING

2 Pages

-

HIGH FRICTION PRE-WASHER

2 Pages

-

EXTRUSION LINES FOR PROFILE

4 Pages

-

LS SERIES

2 Pages

-

HS-HTS SERIES

2 Pages

-

Haul-Off and Cutting Units

2 Pages

-

SOLAR Line

4 Pages

-

BOTTLE TO PACKAGING

2 Pages

-

FRICTION WASHER

2 Pages

-

PET BOTTLES RECYCLING LINES

12 Pages

-

EXTRUSION LINES FOR PIPES

8 Pages

-

TWIN SCREW EXTRUDERS

8 Pages

-

SINGLE SCREW EXTRUDERS

8 Pages