Catalog excerpts

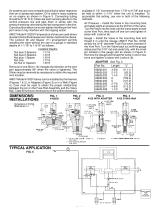

Model 4103 D Temperature Valves Patented FEATURES Protects stationary bearings and other parts from damage due to unsafe high temperature levels. ■ RELIABLE PROTECTION ■ INSTANT RESPONSE ■ COMPACT DESIGN ■ EASE OF INSTALLATION ■ USE WITH OIL, AIR, OR GAS ■ SIZES TO FIT MOST ENGINES APPLICATIONS ■ HIGH BEARING AND FLUID TEMPERATURE DETECTION ■ POWER OR COMPRESSOR CYLINDER OVERLOAD ■ HIGH PACKING GLAND TEMPERATURE DETECTION ■ HIGH DISCHARGE TEMPERATURE DETECTION 6710X Replaceable Fuse Rod Assembly AMOT Model 4103 Temperature Valves provide a low cost, reliable sensor which will initiate a warning or shutdown upon a sudden temperature rise in critical machine parts. Such temperatures may arise from tight, warn or out-ofround bearings, tight packing glands, cracked or broken shafts, torsional vibration, power or compressor cylinder overload, lack of lubricant flow and many other sources. Model 4103 Valves may be used in medium to large stationary bearings and can be applied to liquid systems by installing them in a 6721L Well. For similar capabilities in moving bearing applications, refer to AMOT's Model 4102 Temperature Detectors. Model 4103 has a stainless steel body containing a normally closed valve sealed with a Viton ball. The temperature sensing portion of the 4103 is a thin film of eutectic alloy located near the tip of the Fuse Rod Assembly. This eutectic alloy, less than 0.001 cubic inch in volume, secures a spring loaded fuse rod until the temperature at the sensing end of the rod melts the alloy. The fuse rod is then instantly released and allows the spring-loaded rod to unseat the Viton valve ball. A stainless steel ball is an optional item for use with lube oil as the control medium if high pressures are to be encountered. Generally, the standard Viton ball is recommended for use with air, gas, or lube oil control systems because it provides a leak-tight seal. INSTALLATION AMOT Model 4103 Temperature Valves are the basic sensing units in a safety system and must be tied into the system through connecting tubing. Control pressure may be clean, dry air, or a non-corrosive liquid such as lubricating oil at up to 90 psi.

Open the catalog to page 1

Air systems are more versatile and will give faster response than an oil pressured system. Oil is used in many systems on an engine as shown in Figure 5. Connecting tubing should be 5/16" O.D. Close-tee each sensing device to the control pressure line and pipe them in series with the pressure sensing valve being the last component in the line. Care should be taken not to over tighten the fitting in the Vent port since it may interfere with the tripping action. available in 1/2" increments from 1-7/8" to 9-7/8" and must be held to within +/-1/16" when the unit is installed. To accomplish...

Open the catalog to page 2

HOW TO ORDER When ordering please specify the following: 1. Indicate Model 4103. 2. Mounting Thread: 1/2-20 NF or 5/8-18 NF. 3. Installed Depth, see Table B. 4. Trip Temperature in deg. F: 174, 197, 217, 228, 253, 291, 324, or 343. 5. The following special features if required: a. Stainless Steel Valve Ball (instead of Viton.) b. Thermowells. c. Model 6660L Adapter. d. 6722 Gauge for Adjustment. e. M14 X 2 metric Mounting Threads. Available from UK factory only. f. 1/4BSP(Tr) Valve Port Thread (instead of NPT.) Available from UK factory only. This unit may be ordered using the full...

Open the catalog to page 3

MAINTENANCE It is recommended that the overall safety system be checked monthly for proper functioning by simulating an unsafe condition. AMOT recommends maintenance including visual inspection at the major overhaul of the engine or yearly if lacquering of the lube oil is observed. Excessive lacquering can cause sticking which impairs operation. Unscrew the Detector from the mounting hole and remove Fuse Rod Assembly (4) with a twisting motion. Hold it by the ends and visually examine the eutectic alloy area for exposed alloy. Visible alloy should be a clean fillet around the two brass...

Open the catalog to page 4All AMOT catalogs and technical brochures

-

IP1-Impact-Transmitter

2 Pages

-

7001 Swing Gate

4 Pages

-

4095 2-Way Vent Valve

1 Pages

-

4395 Electric Trip Switch

4 Pages

-

1672 Pressure Sensing Valve

7 Pages

-

4047 Pressure Valve

5 Pages

-

4109 Vibration Sensor

7 Pages

-

Model 8402

6 Pages

-

Model 4123C

5 Pages

-

Model 4418F

9 Pages

-

Model 4420

7 Pages

-

Model 2180

6 Pages

-

XTS-W Bearing Wear Monitor (BWM)

11 Pages

-

SEDM

4 Pages

-

MPD Introduction

12 Pages

-

Control System Solutions

12 Pages

-

Chalwyn Spark Arrestors

4 Pages

-

System Selection Guide

12 Pages

-

Product Selection Guide

20 Pages

-

Intake Air Shutoff Valve

4 Pages

-

Temperature Control Valve

21 Pages

-

Metal Particle Detector

8 Pages

-

2 or 3-Way Pressure Valve

5 Pages