Catalog excerpts

Ordering Guide For Linear Displacement Transducers ABSOLUTE PROCESS CONTROL KNOW WHERE YOU ARE... REGARDLESS

Open the catalog to page 1

FACTORY AUTOMATION In a Gemco position sensor, a current pulse is sent down a magnetostrictive wire in a specially designed waveguide (Figure A). The interaction of this current pulse with the magnetic field created by the movable magnet assembly produces a torsional strain pulse on the wire, which travels at sonic speed along the wire (Figure B). The strain pulse traveling up the wire is sensed by a small induction pickup coil in the head assembly of the LDT. The position of the movable magnet is determined with high precision by measuring the time between the launching of the current...

Open the catalog to page 2

FACTORY AUTOMATION 950IS 950MD Housing Only. This housing accepts all rod style LDTs. 953 Clock (+) 1_|—u Data (+) SSI EtherNet/IP Clock (+) 1_|—u Data (+) SSI EtherNet/IP 7330 1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Open the catalog to page 3

FACTORY AUTOMATION

Open the catalog to page 5

FACTORY AUTOMATION 952A Differential Consult Factory Sensor Dependant

Open the catalog to page 6

FACTORY AUTOMATION Principles Analog Version The analog units are an industry standard and are available with voltage or current outputs. The output format, voltage or current, is hardware specified. The 952, 953, 955 and 957 model LDTs have programmable voltage and current outputs. The output’s count direction, zero and span are all programmable. The 952, 953, 955A and S and 957 units are programmable without any accessories or adaptors. Control Pulse The control pulse signal interface is a differential RS422 output. The maximum cable length for the differential digital LDT is 1,500 feet....

Open the catalog to page 7

FACTORY AUTOMATION Output Types Variable Pulse (PWM) The variable pulse signal interface is a pulse width modulated signal (RS422). The maximum cable length for the differential LDT is 1,500 feet. The LDT can also be configured for external or internal interrogation. External interrogating is when an external device connected to the LDT generates a start pulse. This start pulse should be a minimum of 1.0 microsecond in duration. Within 50 nanoseconds after the leading edge of the start pulse has been received, the LDT will generate an output pulse. The duration of the output pulse is...

Open the catalog to page 8

FACTORY AUTOMATION Output Types SSI (Synchronous Serial Interface) Displacement value is encoded into a 24, 25 or 26 Bit format and transmitted at high speeds. Synchronization in a closed loop system is made easy. A clock pulse train from a controller is used to gate out sensor data: one bit of position data is transmitted to the controller per one clock pulse received by the sensor. The absolute position data is continually updated by the sensor and converted by the shift register into serial information. The sensors fulfill all requirements to the SSI standard for absolute encoders....

Open the catalog to page 9

FACTORY AUTOMATION EtherNet/IP™ is an Industrial Ethernet implementation of the Common Industrial Protocol (CIP), managed by the Open Device Vendor Association (ODVA). EtherNet/IP™ was introduced in 2001 and today is the most developed, proven and complete industrial Ethernet network solution available for manufacturing automation. EtherNet/ IP™ systems require only a single point network connection for both configuration and control, thus simplifying installation and wiring. Our linear displacement transducer line utilizes advanced, proven Magnetostrictive technology to provide highly...

Open the catalog to page 10

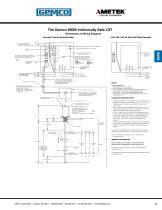

FACTORY AUTOMATION The Gemco 950IS Intrinsically Safe LDT The 950IS can be used in hazardous environments when connected to an approved safety barrier. The LDT is UL & CSA listed for Class I, Group C & D, Class II, Groups E, F, & G and Class III hazardous locations, when properly installed. The term ‘Intrinsically Safe’ is used to describe electronic equipment that has the ability to be mounted directly in explosive atmospheres without chance of an explosion. The term ‘Intrinsically Safe’ pertains to a device’s inability to produce an electrical spark of enough significance to...

Open the catalog to page 11

FACTORY AUTOMATION The Gemco 950IS Intrinsically Safe LDT 0120 NOTE 1: A complete system consists of an LDT, a Gemco Magnet, a Tranceiver and IS Barrier. IS Barrier and Panel Mount Bracket are ordered separately. IS Barrier P/N 04517039. Panel Mount Bracket for Barrier P/N 04517214. Stroke Length NOTE 2: This 950IS model transducer must use a Gemco style magnet. See pages 60-62 for magnet options. Insert stroke length to 0.1 inch. Enter as a fourplace number. Example: A 12.0” stroke enters as 0120. To convert metric strokes, multiply millimeter value by 0.03937 for inch value. NOTE 3: All...

Open the catalog to page 12

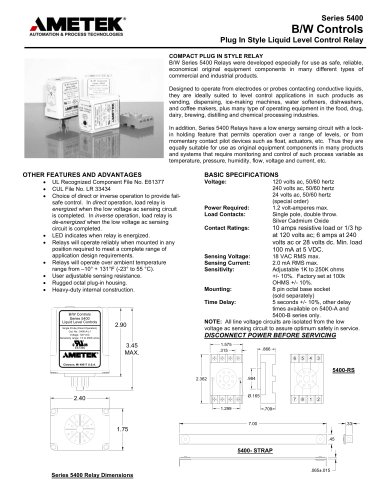

950IS Intrinsically Safe FACTORY AUTOMATION Dimensions & Wiring Diagram The Gemco 950IS Intrinsically Safe LDT Dimensions & Wiring Diagram 24O VOLT 6O HZ APPLICATION (Optional) 120 VOLT 6O HZ APPLICATION TO ASSOCIATED EQUIPMENT 4-2O MA. ISOLATED OUTPUT (1,OOO OHM LOOP CIRCUIT MAXIMUM) MINIMUM RANGE ADJUSTMENT (CLOCKWISE TO DECREASE) SPAN ADJUSTMENT (CLOCKWISE TO INCREASE) NEMA ENCLOSURE AS SPECIFIED (OPEN CHASSIS AVAILABLE) JUMPER FOR LEVEL/RANGE MODE. REMOVE COVER AND MOVE JUMPER IF RANGE MODE IS REQUIRED. (SEE INSTRUCTIONS BELOW FOR DETAILS) GROUND SHIELD AT CONTROLLER END ONLY. TO...

Open the catalog to page 13

FACTORY AUTOMATION Series 950MD Mill-Duty Housing The series 950 Mill-Duty Housing (950MD) was designed for applications where mounting a standalone rod style linear displacement transducer (LDT) is prohibitive. Potential physical damage, environmental conditions or mounting limitations are all elements that are involved in specifying a linear position feedback system that will perform flawlessly for many years to come. The 950MD housing has been designed to eliminate all of the above problems by protecting the LDT from physical and environmental damage such as temperature, corrosives,...

Open the catalog to page 14

FACTORY AUTOMATION 950MD Mill-Duty Housing Due to the fact that the standard Mill-Duty Housing has a mechanical stroke identical to the LDT active stroke, no physical over-stroke exists. If it is possible that the machine being coupled to can extend/retract beyond the stroke supplied, damage to the Mill-Duty Housing and possibly to the machine might occur. To compensate for this we call out fully retracted/fully extended over-stroke dimensions for the Mill-Duty Housing. These values are essentially the additional stroke length added to the Mill-Duty Housing. The reason they are called out...

Open the catalog to page 15All AMETEK Factory Automation catalogs and technical brochures

-

956 eBlok

8 Pages

-

958A

6 Pages

-

Motogard Series

4 Pages

-

7330X Series

2 Pages

-

7330 V Series

2 Pages

-

7330 S & F Series

2 Pages

-

7330 EX/ED Series

2 Pages

-

Industrial Brakes

2 Pages

-

957

6 Pages

-

950IS

3 Pages

-

CATRAC & SnapTrac Catalog

32 Pages

-

B/W Controls Catalog

56 Pages

-

1980 Rotating Cam Limit Switch

20 Pages

-

953A/D/SSI VMAX Gemco LDT

6 Pages

-

950MD Gemco LDT

1 Pages

-

955S Smart BRIK

2 Pages

-

955LC Brik

2 Pages

-

952 BlueOx Gemco LDT

9 Pages

Archived catalogs

-

1986DN - DeviceNet Resolver

2 Pages

-

955D BRIK Gen III Gemco LDT

2 Pages

-

955A Brik Gemco LDT

2 Pages

-

925 Cable Reel Sensor

8 Pages

-

Linear Cable Reel Sensor

8 Pages

-

RESOLVER CATALOG

20 Pages