Catalog excerpts

FABRICATION AUTOMATION CAPABILITIES Stamping Press Control & Automation Solutions

Open the catalog to page 1

OR AUTOMATE THE PRESSES YOU HAVE! With Batch-Run Manufacturing, JIT Delivery And Tighter Product Specifications... The Decision Is No Longer Should You Automate, BUT RATHER HOW TO AUTOMATE YOUR STAMPING PRESSES TO STAY COMPETITIVE. AMETEK, under our GEMCO™ brand name, has been supplying control and automation solutions for mechanical presses for over 35 years. We have a unique product and system mix that allows you to select the level of automation you need to stay profitable. We have also discovered that automation without effective monitoring can be costly. Therefore, we have “damage...

Open the catalog to page 2

At the heart of most press control circuits is a cam switch providing an accurate and reliable indication of crank shaft position. Therefore, the challenge is to have the best, most rugged cam switch on your press. THE GEMCO SERIES 1980 ROTATING CAM LIMIT SWITCH with RESOLVER THE GEMCO SERIES 1980 ROTATING CAM LIMIT SWITCH An Industry Standard For Over 35 Years! GEMCO Series 1980R Rotating Cam Limit Switch with Resolver Custom cam switch packages can include: GEMCO Series 1980 Rotating Cam Limit Switch The Series 1980 Rotating Cam Limit Switch is an industry standard for cam directed press...

Open the catalog to page 3

PRESS AUTOMATION PRODUCTS SOLUTION THE GEMCO SERIES 1996 RAM-SET TM The goals for any press automation project is to reduce die change and setup time and to better manage, coordinate and synchronize automation hardware such as feeders, oilers, blowoffs, robotic arms, etc. for greater press efficiency and part quality. But you may not need a full automation package to achieve these goals. The GEMCO line of press automation products allow you to select the level of automation you need today, and the flexibility to add additional automation devices later. The Ram-Set allows you to automate the...

Open the catalog to page 4

PRESS AUTOMATION PRODUCTS The unit monitors machine / position and delivers absolute position data at 12 bit (4,096 count) resolution to the SLC processor. Standard “Turns Counting” software allows a single turn resolver to be used in multi-turn applications like shut height monitor or control. Brake monitoring in metal stamping applications. In this configuration, automatic calculation of stop time and stop angle is transferred to the I/O image table. In addition, two programmable time limits are available to monitor maximum stop values: the first as a potential maintenance warning, and the...

Open the catalog to page 5

Full press automation means different things to different businesses. How do you find an automation system that is comprehensive, but can also be customized to your press operations, at a price you can afford? The GEMCO Series 1992 Press-Set ™ Rugged GEMCO Resolver Press-Set Relay Output Board Press-Set Automation Controller Full Press Automation at 1/3 the Cost of the Competition The resolver based Series 1992 Press-Set Automation Controller is a modular design that allows you to select features and options to reach the level of automation your business needs to stay competitive. The Series...

Open the catalog to page 6

The need for Automation is greater today then ever before. When press automation works, you remove many of the hands on functions in press operations. Press operators become managers of the process, automated systems do the work. GEMCO Series LDTs Analog, Digital & SSI Outputs 955 BRIK Gen III & 955S Smart BRIK • Low profile LDT. • Analog outputs, 0-10 VDC, +/-10 VDC, 0-5 VDC, +/- 5 VDC, 4-20mA. • Digital output Start/Stop, Control Pulse, and Variable Pulse (PWM). • Programmable zero and span. • Stroke length to 180”. • Wide input voltage range. • Optional floating magnet. • Programmable zero...

Open the catalog to page 7

OTHER PRESSROOM PRODUCTS & ACESSORIES GEMCO Series 952 BlueOx™ Digital LDT • Industry’s toughest transducer– 2,000 G hammer strikes without false signaling. • 30 G random vibration test without false signaling. • Resolution to .001”. • Repeatability to .001% of full stroke. • Up to 144” in 0.1” increments. TRANSDUCER MOUNTING: The proper mounting of the linear displacement transducer is critical to insure proper operation of the system. While no hard and fast rule applies to mounting the transducer, the following should be considered: A) The transducer should be mounted between a fixed...

Open the catalog to page 8

RESOLVERS High Resolution Resolver Transducers for Heavy Duty Industrial Applications For over 30 years, GEMCO’s 1986 Resolver Transducers have been a standard solution for harsh industrial applications such as steel mills and stamping press automation. GEMCO has always been a pioneer in the design and manufacturing of “built to order” resolver packages. We can mechanically and electrically match any competitor’s package while improving on the overall design to enhance the performance, accuracy or durability. Through our wide range of materials for construction and precision gear reducers...

Open the catalog to page 9

RESOLVERS Special Resolver Assemblies For applications requiring two electrically separate but redundant resolver signals, GEMCO offers a unique package that provides one resolver assembly with two internal resolvers tied to the main input shaft. The resolver outputs can be electrically the same or different from each other. We utilize a precision antibacklash gear head with two resolvers driven at a 1:1 ratio with the main input shaft. Each resolver is then wired to a seven pin amphenol connector that matches the requirements of the interface device. The resolver would typically be...

Open the catalog to page 10

CATRAC Get On The Right Track With Catrac Cable & Hose Carriers CATRAC is used on various types of machinery as a means of safely and efficiently conveying power, electrical, air, or fluid (or a combination of these) to equipment in motion. CATRAC is designed to be maintenance free and to protect cables and hoses from abrasion, wear, and twisting. A wide variety of options are available. The center pivot design allows for smoother cycling and minimal hose movement. The CATRAC design offers “No Pinch Points” to insure operator safety. Standard side links are high tensile steel for maximum...

Open the catalog to page 11All AMETEK Factory Automation catalogs and technical brochures

-

956 eBlok

8 Pages

-

958A

6 Pages

-

Motogard Series

4 Pages

-

7330X Series

2 Pages

-

7330 V Series

2 Pages

-

7330 S & F Series

2 Pages

-

7330 EX/ED Series

2 Pages

-

Industrial Brakes

2 Pages

-

957

6 Pages

-

Linear Displacement Transducers

86 Pages

-

950IS

3 Pages

-

CATRAC & SnapTrac Catalog

32 Pages

-

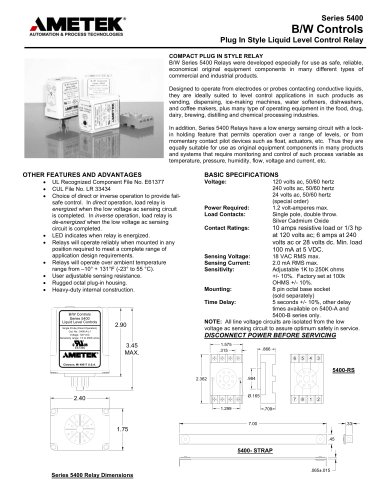

B/W Controls Catalog

56 Pages

-

1980 Rotating Cam Limit Switch

20 Pages

-

953A/D/SSI VMAX Gemco LDT

6 Pages

-

950MD Gemco LDT

1 Pages

-

955S Smart BRIK

2 Pages

-

955LC Brik

2 Pages

-

952 BlueOx Gemco LDT

9 Pages

Archived catalogs

-

1986DN - DeviceNet Resolver

2 Pages

-

955D BRIK Gen III Gemco LDT

2 Pages

-

955A Brik Gemco LDT

2 Pages

-

925 Cable Reel Sensor

8 Pages

-

Linear Cable Reel Sensor

8 Pages

-

RESOLVER CATALOG

20 Pages