Catalog excerpts

LIQUID LEVEL TECHNOLOGY Ordering Guide & Technical Information Continuous & Point Liquid Level Sensors ABSOLUTE PROCESS CONTROL KNOW WHERE YOU ARE... REGARDLESS

Open the catalog to page 1

FACTORY AUTOMATION FROM its inception in 1933, BjW Controls was on the leading edge of liquid level control. It all started with BIW's original idea of taking advantage of the electrical conductivity of most liquids to achieve floatless level control. Since then the idea has earned worldwide acceptance as the most reliable and versatile system of its kind. It has been utilized throughout such industries as the food, bever- age, dairy, pharmaceutical, and chemical processing indus- tries; in municipal waterworks and sewage treatment plants; and for numerous other commercial and industrial...

Open the catalog to page 3

Induction Relays THE SERIES 1500 INDUCTION RELAY WITH FIELD CONVERTIBLE CONTACTS PROVIDES A VERSATILE AND RELIABLE LIQUID LEVEL CONTROL As the pioneer producer of electrode-activated float- less level control systems, we acquired broad, practi- cal experience in developing and manufacturing equip- ment to meet the requirements of a wide range of liq- The Series 1500 Induction Relays provide versatile and economical means of controlling many proces- sing and production functions from remote locations with the safety inherent in a low energy sensing cir- cuit that is isolated from the AC...

Open the catalog to page 4

FACTORY AUTOMATION A floatless liquid level control system consists of a relay of the proper type, a holder designed to support one or more elec- trodes or probes in the liquid container. The corrosion resistant electrodes for all B|W induction relays are quite similar, differing only in contact arrange- As shown in diagrams below, the laminated core of the relay is H shaped. The primary coil is assembled to the upper bar of the core, and the secondary coil for the elec- trode is placed on the lower bar An armature located below the legs of the R core is connected to an insulated arm...

Open the catalog to page 5

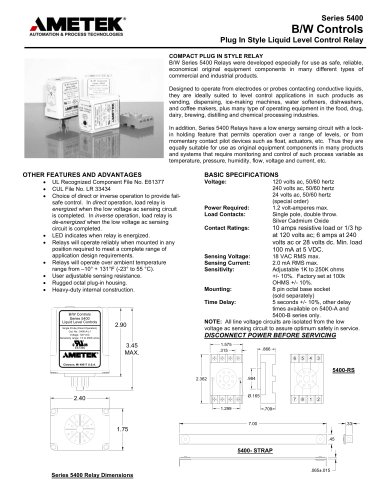

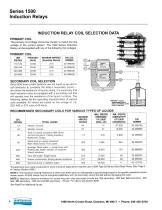

Induction Relays INDUCTION RELAY COIL SELECTION DATA PRIMARY COIL The primary coil voltage should be chosen to match the line voltage of the control system. The 1500 Series Induction Relay can be supplied with any of the following line voltages: PRIMARY COIL "Exceptionally pure water produced for some industrial applications requires use of B|W Type 52-Series Solid-State Relay, (See Page 5 NOTE1: The maximum closing resistance in ohms over which each coil will operate is approximately equal to the specific resistance values shown above. All B W relays may be energized indefinitely with the...

Open the catalog to page 6

FACTORY AUTOMATION MANUAL RESET RELAYS BIW Manual Reset relays are basic induction reiays equipped with a N.O. or N.C. reset button which permits an operator to reestablish the electrode for high or low level cutoff operation. Once a pump has been stopped by the liquid leaving or contacting the electrode, it cannot be started again until the relay has been manually reset by means of the pushbutton. Available as single pole or double pole — normally open or normally closed —■ and as single pole. double throw relays. When ordering, please specify oper- ation desired. NOTE: When ordering a...

Open the catalog to page 7

Induction Relays REFER TO SERVICE BULLETIN FORM 511 FOR DETAILED WIRING CAUTION: Electrodes are terminals of live electrical circuits and must be installed to prevent accidental contact by personnel. Control power must be disconnected before servicing. * A GOOD DEPENDABLE GROUND RETURN CONNECTION TO THE LIQUID IS REQUIRED. t For direct wiring to a 208-240VAC, 1 phase load device, 2 load contacts are required; see Series 1500E, F & H Relays. 1080 North Crooks Road, Clawson, Ml 48017 • Phone: 248-435-0700

Open the catalog to page 8

FACTORY AUTOMATION REFER TO SERVICE BULLETIN FORM 511 FOR DETAILED WIRING CAUTION: Electrodes are terminals of live electrical circuits and must be installed to prevent accidental contact by personnel. Control power must be disconnected before servicing. * A GOOD DEPENDABLE GROUND RETURN CONNECTION TO THE LIQUID IS REQUIRED. $ For direct wiring to a 208-240VAC, 1 phase load device, 2 load contacts are required; see Series 1500E, F & H Relays. Toll Free: 800-635-0289 • Email: apt.orders@ametek.com • Web: www.ametekapt.com LIQUID LEVEL TECHNOLOGY

Open the catalog to page 9

Induction Relays CONDUCTIVE LIQUIDS With the exception of products such as oil, gasoline, ani- mal fats and other similar products, most liquids and some moist bulk materials have sufficient conductivity to use BIW level detecting relays. The Series 1500 relay can be used on liquids with resistance up to about 90,000 ohm-cm (conductivity to 11 micromho/cm). For liquids with higher resistance the BIW Series 5200 relays must be used for applications up to 12 megohms resistance. Liquids such as milk and beer, and some pharmaceutical products will foam during processing. The liquid phase is...

Open the catalog to page 10

FACTORY AUTOMATION Shown with cover remove <J CROSS REFERENCE Consult Factory For Special Line Heavy Duty Pilot 120 to 600 VAC EXAMPLE: A liquid level application requires 1 N.O., 1 N.C. and 1 N.O. Holding Contact. The line voltage available is 115 VAC It is desired to detect the level of storm run-off water The installa- tion is outside requiring a NEMA4 water tight enclosure. Toll Free: 800-635-0289 • Email: apt.orders@ametek.com • Web: www.ametekapt.com ^J?.?0"*"*}*,. 11 LIQUID LEVEL TECHNOLOGY

Open the catalog to page 11

Induction Relays Manual Reset reset relay. Consult factory manual reset 1080 North Crooks Road, Clawson, Ml 48017 • Phone: 248-435-0700

Open the catalog to page 12

FACTORY AUTOMATION OPEN CHASSIS GENERAL PURPOSE ENCLOSURE Size 8 pan head screws with captivated wire clamping plate Approx. Shipping weight Approx. shipping weight: 5 pounds with relay. WATER & DUST TIGHT ENCLOSURE EXPLOSION-PROOF ENCLOSURE Approx. shipping weight: 9 pounds with relay. Class II, Group E.FIC Approx. shipping weight: 12 pounds with relay. OIL-TIGHT ENCLOSURES Approx. shipping weight: 7 pounds with relay. Toll Free: 800-635-0289 • Email: apt.orders@ametek.com • Web: www.ametekapt.com LIQUID LEVEL TECHNOLOGY

Open the catalog to page 13All AMETEK Factory Automation catalogs and technical brochures

-

956 eBlok

8 Pages

-

958A

6 Pages

-

Motogard Series

4 Pages

-

7330X Series

2 Pages

-

7330 V Series

2 Pages

-

7330 S & F Series

2 Pages

-

7330 EX/ED Series

2 Pages

-

Industrial Brakes

2 Pages

-

957

6 Pages

-

Linear Displacement Transducers

86 Pages

-

950IS

3 Pages

-

CATRAC & SnapTrac Catalog

32 Pages

-

1980 Rotating Cam Limit Switch

20 Pages

-

953A/D/SSI VMAX Gemco LDT

6 Pages

-

950MD Gemco LDT

1 Pages

-

955S Smart BRIK

2 Pages

-

955LC Brik

2 Pages

-

952 BlueOx Gemco LDT

9 Pages

Archived catalogs

-

1986DN - DeviceNet Resolver

2 Pages

-

955D BRIK Gen III Gemco LDT

2 Pages

-

955A Brik Gemco LDT

2 Pages

-

925 Cable Reel Sensor

8 Pages

-

Linear Cable Reel Sensor

8 Pages

-

RESOLVER CATALOG

20 Pages