Catalog excerpts

PRODUCT CATALOG TECHNICAL & INDUSTRIAL PRODUCTS WELCOME TO SOLUTION CITY®

Open the catalog to page 1

The impeller blades passing the inlet port draw air or other gases into the blower. The impeller blades then, by centrifigal action, accelerate the air outward and forward. Here the "regenerative” principle takes effect as the air is turned back by the annular shaped housing to the base of the following blades, where it is again hurled outward. Each "regeneration” imparts more pressure to the air. When the air reaches the stripper section at the outlet (the stripper is the part of the blower located between the inlet and the outlet in which the annulus is reduced in size to fit closely to...

Open the catalog to page 3

A: Nine Major Blower Application Areas B: Product Dimensional Listing C: Industrial / Chemical Processing Blowers 3. HP High Pressure Regenerative Blower DR 555 & CP 555 C23 7.5 HP High Pressure Regenerative Blower DR 808 & CP 808 C35 15.0 / 20.0 HP High Pressure Regenerative Blower DR 909 & CP 909 C45 20.0 HP High Pressure Regenerative Blower DR P13 C51 20.0 / 30.0 HP High Pressure Regenerative Blower DR 14 & CP 14 C55 40.0 HP High Pressure Regenerative Blower D: Environmental / Chemical Processing Blowers .5 HP Sealed Regenerative w/Explosion-Proof Motor EN...

Open the catalog to page 4

F: Application Specific Blowers Insrument Grade Regenerative Blower Minispiral MDC F3 Variable Flow Regenerative Blower Minispiral 12/24V HDC F5 Variable Flow Regenerative Blower Minispiral 12V HDC Extra Flow / Extra Wide Fat Boy F7 Variable Flow Regenerative Blower SPIRAL Simplex SL2 F9 Insrument Grade Regenerative Blower SPIRAL Duplex SL4 F11 Insrument Grade Regenerative Blower SPIRAL Duplex SL5 F13 Insrument Grade Regenerative Blower Nautilair F15 Remote Drive (Motorless) Blowers MD 101 Magnetic-Drive F21 Regenerative Blower Filtration - Inlet Filter (Single...

Open the catalog to page 5

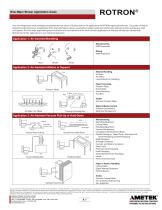

Nine Major Blower Application Areas Your own imagination and knowledge are probably the best source of in-plant and on-site applications for ROTRON regenerative blowers. This guide will help to pinpoint and stimulate your consideration of the many alternative sources we provide to replace costly and maintenance intensive suction and pressure units and systems. The nine major application groups are listed and a cross reference of the most common applications by industry will help you identify both identical and similar applications in your industrial operations. Application 1: Air-Assisted...

Open the catalog to page 6

Nine Major Blower Application Areas Application 4: Air & Gas Sampling, Boosting, or Circulating Air Pollution Control Air Sampling Air Stream Release Monitoring Fire Prevention Air Sampling Flue Gas Sampling Stack Lens Lens Light Beam Transmissometer Lens Purging Instrument Plastics Handling Desiccant Dryer Bed Regeneration Foundry Combustion Air Boost Instrumentation Glove Box Pressurizing Incubator Air Circulation Weather Measurement Sampling Manufacturing Combustion Air Boost Natural Gas Boost Oil Demisting Pharmaceutical Clean Room Air Circulation Oxygen Generator Combustion Chamber...

Open the catalog to page 7

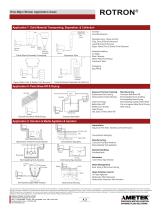

Nine Major Blower Application Areas Application 7: Solid Material Transporting, Separation, & Collection Bin Tube Carrier Pressure Blower Rotary Airlock Discharge To Process Dilute Phase Pneumatic Conveying Foundry Sand Reclamation Manufacturing - Waste Control Chip, Dust, & Particle Removal Liquid & Solvent Removal Paper, Plastic Film, & Textile (Trim) Removal Material Handling Air Slides Blast Cleaning Dilute Phase Conveying Pneumatic Tube Pneumatic Tube Paper, Plastic, Film, & Textile (Trim) Removal Collection Chamber General Material Separation & Collection Application 8: Parts Blow-Off...

Open the catalog to page 8

Product Dimensional Listing Note: Model weight will vary by HP and voltage. Refer to individual specification sheets to verify. AMETEK PRECISION MOTION CONTROL DYNAMIC FLUID SOLUTIONS This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual...

Open the catalog to page 9

AMETEK Dynamic Fluid Solutions' ROTRON brand has long been a world leader in regenerative blower technologies, bringing regenerative advantages to a new level, providing quiet, maintenance-free, oil-free operation. Our industrial DR (Domestic Regenerative) blowers include: • Rugged cast aluminum housing, cover, impeller, and muffler tower • Removable cast iron flanges bolted to a sheet metal manifold • TEFC motors on single-ended models, ODP motors on all double-ended models • Carbon steel shaft and zinc plated hardware • Permanently sealed motor bearings for 20,000-25,000 hours life Our CP...

Open the catalog to page 10

Voltage - ROTRON motors are designed to handle a broad range of world voltages and power supply variations. Our dual voltage 3 phase motors are factory tested and certified to operate on both: 208-230/415-460 VAC-3 ph-60 Hz and 190-208/380-415 VAC-3 ph-50 Hz. certified to operate on both: 104-115/208-230 VAC-1 ph-60 Hz and 100-110/200-220 VAC-1 ph-50 Hz. Special wound motors can be ordered for voltages outside our certified range. Operating Temperaturs - Maximum operating temperature: Motor winding temperature (winding rise plus ambient) should not exceed 140°C for Class F rated motors...

Open the catalog to page 11

Industrial / Chemical Processing Blowers • Manufactured in the USA - ISO 9001 and NAFTA compliant • CE compliant - Declaration of Conformity on file • Maximum flow: 13 SCFM • Maximum pressure: 13.5 IWG • Maximum vacuum: 13.5 IWG • Standard motor: 1/8 HP, TEFC • Cast aluminum blower housing, impeller & cover; slip-on steel flanges • UL & CSA approved motor with permanently sealed ball bearings • Inlet & outlet internal muffling • Quiet operation within OSHA standards MOTOR OPTIONS • International voltage & frequency (Hz) • Various horsepowers for application-specific needs BLOWER OPTIONS •...

Open the catalog to page 12All AMETEK Dynamic Fluid Solutions catalogs and technical brochures

-

Windjammer pro

6 Pages

-

Minijammer Blower

2 Pages

-

Microjammer Blower

2 Pages

-

AMETEK Nautilair Blower

2 Pages

-

ROTRON TDS

2 Pages

-

Windjammer Brushless Blowers

136 Pages

-

rotron transportation catalog

54 Pages

-

fuel cell advantage sheet

2 Pages

-

Water Aeration Blowers

2 Pages

-

Textile Blowers

2 Pages

-

Precision Cleaning

2 Pages

-

Packaging Blowers

2 Pages

-

Materials Handling

2 Pages

-

Electroplating Blowers

6 Pages

-

AMETEK Transportation

39 Pages

-

AMETEK Blowers

133 Pages

Archived catalogs

-

Nautilair Combustion Blowers

22 Pages

-

Pittman Motors

104 Pages

-

Blowers

128 Pages

-

Regenerative Blowers

196 Pages