Website:

AMETEK Drexelbrook

Website:

AMETEK Drexelbrook

Group: AMETEK

Catalog excerpts

DATA SHEET NOW WITH MULTI-CAL CALIBRATION SOFTWARE! Use the Best For over 50 years, Drexelbrook has been the world’s leader in capacitive based measurements by providing reliable and accurate products at a reasonable cost. We offer the highest pressure and temperature ratings in the industry, 1500 PSI and temperatures up to 450°F. Easy Configuration with Built-in Display and Keypad All Universal IV CM comes from the factory pre-calibrat-ed and requires only one point validation. Field configuration can be done from anywhere along the two-wire loop with our STExplorer PC Software. You can also configure via local display / keypad without the need for laptop or handheld communicators. Worldwide Approvals The Universal IV CM Model has been approved for Class I, Div1, and Zone 0 hazardous locations. FM, FMc, ATEX, as well as IECEx approvals are available. Eliminate Routine Maintenance The Universal IV CM ignores paraffin and other coatings that buildup on the probe. No need to take apart the spool pieces and tie-off large pipelines. The Universal IV CM can be configured as either an insertion probe with a NPT fitting (Reference our Universal IV CM Model with Temperature compensation) or as a flanged mounted inline spool probe for most common pipe diameters. Temperature Compensation The dielectric constant of crude oil can change with any changes in temperature. These changes may cause standard cut monitors to change without any variance in water content. The Universal IV Water Cut Monitor measures product temperature internally and calculates a true water cut reading at any temperature within the process temperature range. Multi-Cal Density Compensation The density or API gravity of crude oil changes due to many factors including temperature, material changes as well as the region and or formation that it is being pulled from. These changes will cause standard cut monitors to mistakenly attribute changes in density to changes in water content if not properly accounted for. The new Drexelbrook UIV CM with Multi-Cal Density Compensation utilizes system measured variables such as temperature, flow and density from a customer supplied Coriolis meter and calculates the corrected value for true water content. Multi-Cal software allows for up to 10 different density calibration points to reduce recalibration requirements, thus insuring maximum accuracy load to load. APPLICATIONS Automatic Well Testing (AWT) Lease Automatic Custody Transfer (LACT) Basic Sediment and Water (BS & W) Separation Vessels Truck Unloading Pump Protection Dielectric Analysis Machinery Lube Oil Monitoring

Open the catalog to page 1

Universal IV™ Density Compensated Water Cut Meter Operating Overview for Density Compensation The Drexelbrook UIV CM with Density compensation employs the use of a remote electronics housing (Density Compensation Module –DCM) to perform the compensation adjustments for density changes in the process flow. The DCM is identical to the housing used on standard cut monitor system and meets all hazardous area approvals. It can be mounted in close proximity to the cut monitor, anywhere on the LACT skid or in the non hazardous electronics control area. To perform density compensation the...

Open the catalog to page 2

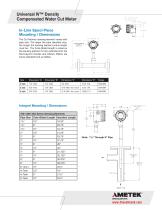

Universal IV™ Density Compensated Water Cut Meter In-Line Spool Piece Mounting / Dimensions The Cut Monitor sensing element varies with pipe size. The larger the pipe diameter size, the longer the sensing element active length must be. The Cote-Shield length is sized so the sensing element is fully extended into the fluid beyond nozzles and elbows. Below are some standard look up tables. Integral Mounting / Dimensions 700-1202-4XX Series Sensing Elements

Open the catalog to page 3

Technology RF Admittance / Capacitance Supply Voltage 19-30VDC, 4-wire system Ouput/Digital Protocol 4-20mA, HART Compatible with HART®7 Accuracy and Resolution Water Cut Nominal Water Cut Water Cut Range Variance* Resolution** *The measurement accuracy of an inline, dynamic water cut measurement is dependent upon many process variables including: oil dielectric consistency, fluid velocity at the sample point, mounting geometry and homogeneity of the oil/ water emulsion. The values above represent nominal water cut measurement variances for a properly installed sensor under...

Open the catalog to page 4

Base Model Number U Universal IV System Type DO Density Cut Monitor model: 100 KHz, 0° Phase Digital Protocols Future Use 0 Future Use Approvals 9 FM/FMcXP with Density Cut Monitor A ATEX d with Density Cut Monitor B IECEx d with Density Cut Monitor Electrical Connection 3 3/4" NPT without external ground with Density Cut Monitor 4 M20 with external ground / Equipotential Bonding with Density Cut Monitor 5 3/4" NPT with external ground / Equipotential Bonding with Density Cut Monitor Surge / Noise Suppression 0 No additional filtering required 1 Signal RFI (Integral or...

Open the catalog to page 5

Base Model Number U Universal IV Base Model System Type DR Density Cut Compensation Module Digital Protocols 1 4 Wire 4-20mA w/HART® Future Use 0 Future Use Approvals 9 FM/FMcXP with Density Cut Monitor A ATEX d with Density Cut Monitor B IECEx d with Density Cut Monitor Electrical Connection 3 3/4" NPT without external ground with Density Cut Monitor 4 M20 with external ground / Equipotential Bonding with Density Cut Monitor 5 3/4" NPT with external ground / Equipotential Bonding with Density Cut Monitor Surge / Noise Suppression 0 No additional filtering required Integral /...

Open the catalog to page 6

Universal IV™ Density Compensated Water Cut Meter Model Numbering - Probe Dimensions and Process Connection (In Line-Spool Probe) Spool Piece Probe Pipe Size 002 D.X 17" Face to Face D.X 32" Face to Face D.X 32" Face to Face D.X 17" Face to Face D.X 32" Face to Face, Integral, No Dual Seal D.X 32" Face to Face, Integral, No Dual Seal D.X 17" Face to Face, Integral With Temp. Comp., No Dual Seal D.X 32" Face to Face, Integral With Temp. Comp., No Dual Seal D.X 32" Face v Face, Integral With Temp. Comp., No Dual Seal Material Type Carbon Steel 316 Stainless Steel - Flange Type 0 1 5 150...

Open the catalog to page 7All AMETEK Drexelbrook catalogs and technical brochures

-

Multipoint II Series

2 Pages

-

ClearLine Series

2 Pages

-

1500 SERIES RELAY

2 Pages

-

7014 and 7010 Series

2 Pages

-

Unifloat Level Sensors

9 Pages

-

Universal IV ™ CM Model

8 Pages

-

Model 375

4 Pages

-

Model 575 Series

5 Pages

-

Model 575P

4 Pages

-

Model 675

5 Pages

-

Dumpstar Series

2 Pages

-

Plugged Chute Detector

4 Pages

-

Universal II Series

2 Pages

-

Level Mate III

4 Pages

-

Model 575S

5 Pages

-

Model SST Slim-Line

4 Pages

-

Model SDT

4 Pages

-

Total Tank Level System

6 Pages

-

Drexelbrook Level Measurement

16 Pages

-

DR6300 Series

17 Pages

-

DR5200 Series

17 Pages

-

DR7000 Series

4 Pages

-

Z4-Series

6 Pages

-

Universal IV Sales Brochure

10 Pages

-

Coal and Fly Ash Solutions

6 Pages

-

RXL Series, IntelliPoint

4 Pages

-

401-400 Series

4 Pages

-

Model DDMC

8 Pages

-

Accessories Drexelcage

2 Pages

-

Point Level

5 Pages

Archived catalogs

-

USonic™ Series

4 Pages

-

PNT Series, ThePoint

4 Pages

-

Model SDT

4 Pages

-

701X Series Data Sheet

2 Pages

-

CM3 Series Cut Monitor

4 Pages

-

DR7000

4 Pages