Catalog excerpts

A-Las™ Automated Laser Alignment System™ P/N: 990014 BENIFITS Turns days of costly downtime and labor into a push of one button and a few seconds Reduces the necessity for personnel to access the beam path promoting an accident free environment Totally eliminates the labor costs of manual alignment increasing productivity and cash flow Eliminates reliance on outside contracted labor eliminating schedule delays and reducing unnecessary cost Decreases machine scheduled and unscheduled downtime increasing machine productivity and revenue Eliminates contamination of optics in sealed beam path reducing replacement costs and inventory Identifies failed optical components reducing costly troubleshooting and downtime FEATURES FIG 1 depicts the information presented to an operator. two significant areas are the upper right hand and lower left hand zones. The right hand section shows the current beam position, white spot, blue crosshairs, and the red reference crosshairs. Located down and right of the current beam position is the aligned location or targeted position. The lower left hand section, direction arrow area, provides manual position control. Directly above is a Correct Offset button that corrects both axes simultaneously. To the right of the direction arrow area is the Auto Correct button which, when A-LasTM has been configured with multiple modules, corrects the alignment of each module in sequence. Useable process laser wavelengths 100-400, 800-30,000nm; contact factory for 400-800nm Process laser power range .001-20,000 Watts Network and control multiple stations from one desktop computer allowing one person to diagnose and correct multiple machines American Laser Enterprises, LLC. PO Box 309 Novi, MI 48376 Phone: 248-449-3714 Fax: 248-449-7631 Email: info@a-l-e.net Web: a-l-e.net FIG 2 shows the result of correcting the misalignment in FIG 1 utilizing either Correct Offset or Auto Correct.

Open the catalog to page 1All American Laser Enterprises catalogs and technical brochures

-

High Power WELDING HEAD

1 Pages

-

CLADDING HEAD - LATERAL FEED

1 Pages

-

CLADDING HEAD - FIBER LASER

1 Pages

-

ABZ WRIST - CUTTING SYSTEM

1 Pages

-

CUTTING HEAD W/ Z-AXIS 90°

1 Pages

-

CUTTING HEAD Ø1.0" - f3.5"

1 Pages

-

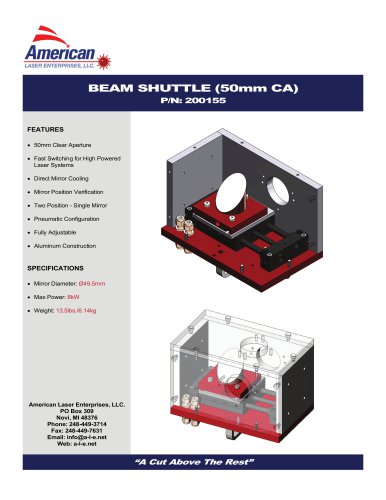

BEAM SHUTTLE (50mm CA)

1 Pages

-

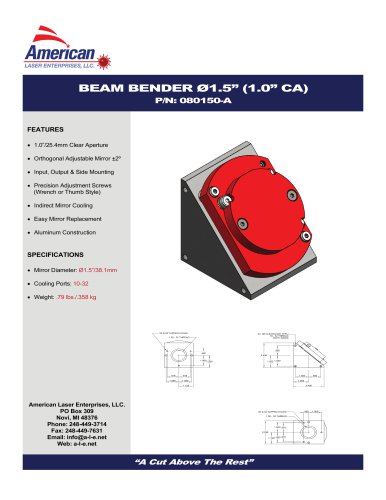

BEAM BENDER Ø1.5" - 1.0" CA

1 Pages

-

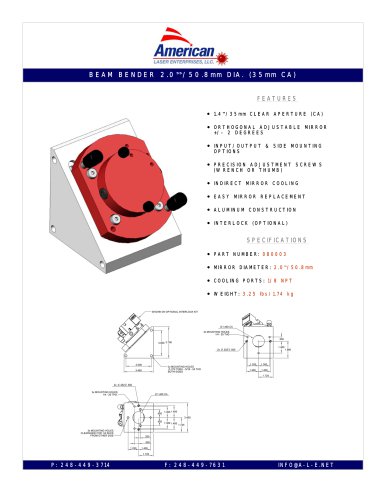

BEAM BENDER Ø2.0" - 1.4" CA

1 Pages

-

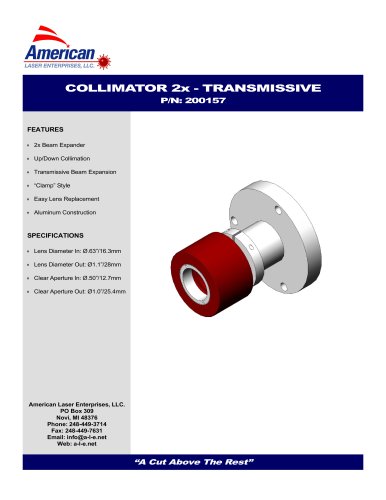

COLLIMATOR 2X - TRANSMISSIVE

1 Pages

-

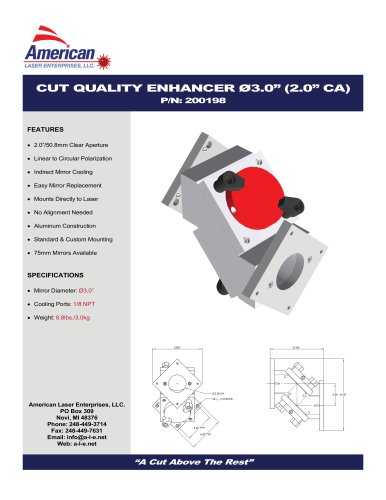

CUT QUALITY ENHANCER Ø2.0"

1 Pages

Archived catalogs

-

Laser Component Parts

48 Pages

-

CUTTING HEAD Ø1.5" - f7.5"

1 Pages

-

COLLIMATOR 2X - TRANSMISSIVE

1 Pages

-

COLLIMATOR 1.6X - REFLECTIVE

1 Pages

-

CUT QUALITY ENHANCER Ø3.0"

1 Pages

-

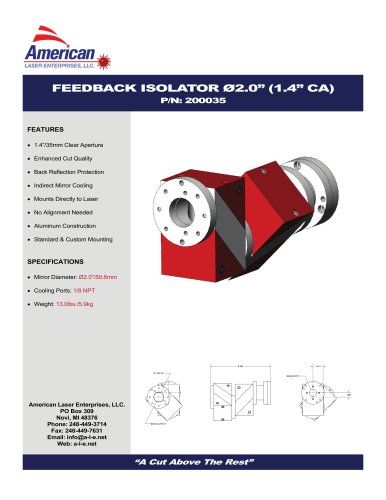

FEEDBACK ISOLATOR Ø2.0"

1 Pages

-

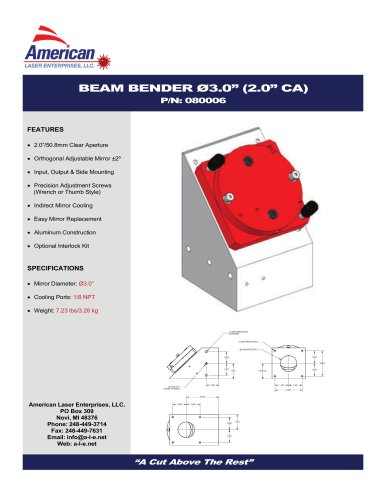

BEAM BENDER Ø3.0" - 50mm CA

1 Pages