Website:

AMANDUS KAHL

Website:

AMANDUS KAHL

Group: KAHL Holding

Catalog excerpts

WOOD PELLETING PLANTS BESPOKE FOR CAPACITIES UP TO 8000 KG/H PER PRESS

Open the catalog to page 1

Depending on the input product, which can be dry wood shavings, wet sawdust, wood chips or even whole tree trunks, different process steps are required. Depending on the requirements on the finished wood pellets, we need for example a product with a granular size of approx. 4 mm and a residual moisture content of approx. 10 % directly before the pelleting press. This means tree trunks require the maximum process steps: debarking, wet chipping, drying, dry grinding, pre-conditioning, pelleting, cooling, storing or loading. If wet sawdust is available, for example, drying will be the first...

Open the catalog to page 2

WOOD PELLETS: THE BEST-SELLING AND HIGH-QUALITY PRODUCT For decades, KAFIL pelleting plants have been applied successfully for compacting organic products of different particle sizes, moisture contents and bulk densities. We are constantly developing our machines in order to improve their capacities and economic efficiency. KAFIL pelleting presses are particularly appropriate for products which are difficult to pellet. OUR SERVICES • Consultation, assistance in obtaining approval, engineering, commissioning, installation, and after-sales service. • KAHL supply turn-key plants for the...

Open the catalog to page 3

Soft wood pellets KAHL WOOD PELLETING PLANTS AMANDUS KAHL offer pelleting presses with a drive power from 3 kW to 500 kW. In total, 11 different sizes are available. The production capacities of most plants range between 1.5 and 8 t/h per press. Smaller plants work efficiently, too. Larger plants of up to 40 t/h are provided for industrial production of pellets. PLANT FOR THE PRODUCTION OF DINPLUS WOOD PELLETS, WITHOUT HAMMER MILL, UP TO 5 T/H Pre-/wet grinding plant for wood chips Drying plant for wood chips Storage facilities for dried chips

Open the catalog to page 4

Hard wood pellets QUALITY CAN BE RECOGNISED AT FIRST GLANCE! HIGH PELLET QUALITY = HIGH BULK DENSITY HIGH BULK DENSITY = BETTER COMBUSTIBILITY Due to the great variety of input products and the different plant sizes available, we plan and calculate KAHL plants according to the requirement of the customer considering the capacity and the local conditions. There is, for example, the small pelleting plant for only 300 kg/h for the cabinetmaker's workshop pelleting its own dry wood waste. Such a plant only works 4 hours a day and still is economically efficient. Pelleting and cooling plant...

Open the catalog to page 5

HIGH-PERFORMANCE PRESSES OF KAHL COMPETENCE FOR INDUSTRIAL WOOD PELLETING PLANTS KAHL FABRIC BELT DRIERS Since 1925 AMANDUS KAHL have built pelleting plants. We attend to our customers with maintenance and service throughout the service life of the plant. These are generally several decades. Our own technical service is available for our customers on site. Thanks to the state-of-the-art control and regulation technique, we use all possibilities for remote maintenance of our plants via Internet connections. The biomass is pressed through a die by pan grinder rollers, formed into endless...

Open the catalog to page 6

KAHL FLAT DIE PELLETING PRESSES DEMONSTRATE QUALITY IN ALL DETAILS Pan grinder head with guide plates for the exact product distribution Reinforced cutting devices Breathing air filter prevents moisture in the gear interior Reinforced press chamber Cutting device for smooth edges and less fines Oil filter with flow meter Hydraulic nut with quick-action coupling Pan grinder head stop for optimum adjustment of rollers and die Gear oil spraying plant protects against overheating Insertion of the clamping ring Large bearings = long service lives Long service lives = less wear costs Good pellet...

Open the catalog to page 7

BESPOKE PLANTS FOR HIGH-QUALITY PELLETS OUR OWN PRODUCTION LINE GUARANTEES QUALITY All main machines of the pelleting plant, i.e. pan grinder mills, hammer mills, belt driers, pelleting presses and coolers, are produced in our factory at Reinbek near Hamburg. Here, we also have our own pilot plant for carrying out pelleting tests with the most different products, realising feasibility studies and generating a reliable data base for future scale-up.

Open the catalog to page 8

PRESSES FROM KAHL: CONSTRUCTION OF HEAVY MACHINERY PAYS OFF PELLETING STATION UP TO 60 T/H Conveying and distribution unit Pelleting plant Cooling and aspiration system MACHINE AND PLANT OPTIMISATION As for energy efficiency, we consider the complete plant, from the reception facilities to the finished product silos. With an improved press control, clear machine monitoring and the use of a so-called traffic light control system, downtimes can be avoided and the service lives positively influenced.

Open the catalog to page 9

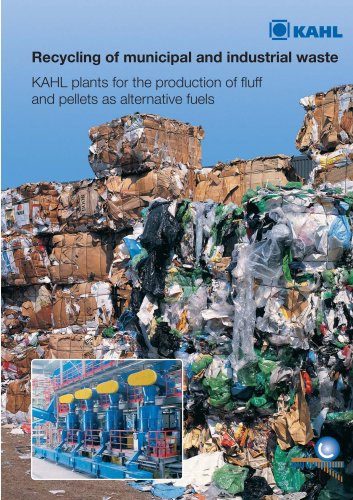

KAHL AS PARTNER OF THE RECYCLING INDUSTRY KAHL PELLETING PRESSES ARE EXTREMELY SUITABLE FOR COMPACTING A LARGE VARIETY OF PRODUCTS. Pelleting of renewable raw materials for energy recovery has been a topic for KAHL for more than 30 years, after receiving corresponding research assignments following the energy crisis in the i97o's. Straw and dried forage pelleting plants have formed part of our delivery programme since then, too. So, we can rely on long-standing experience. WASTE TYRES DOMESTIC WASTE POSSIBLE APPLICATIONS OF THE KAHL PELLETING PRESS • Wood waste • Sawdust • Wood and sanding...

Open the catalog to page 10

PLANT EXAMPLES

Open the catalog to page 11

AMANDUS KAHL GmbH & Co. KG Dieselstrasse 5–9 · 21465 Reinbek Hamburg, G

Open the catalog to page 12All AMANDUS KAHL catalogs and technical brochures

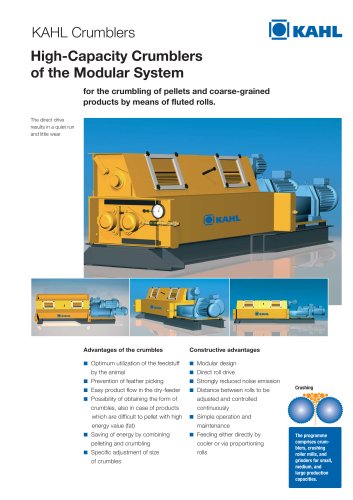

-

PELLET MILLS

9 Pages

-

AK01 KAHL ROTOSPRAY®

2 Pages

-

KAHL High-Speed Mixer SMW

2 Pages

-

KAHL Annular gap expander

4 Pages

-

KAHL AKANA Hammer Mills

2 Pages

-

KAHL Press O-500/390

2 Pages

-

KAHL Continuous Mixer

2 Pages

-

KAHL Batch Mixers

2 Pages

-

Crown Expander OEK

2 Pages

-

Belt driers and coolers

8 Pages

-

Pelleting Presses

8 Pages

-

Annular Gap Expander

4 Pages

-

KAHL Fabric Belt Drier

4 Pages

-

Feedmills, Plants, and Machines

12 Pages

Archived catalogs

-

Waste Tyre Recycling Plants

6 Pages