Website:

AMANDUS KAHL

Website:

AMANDUS KAHL

Group: KAHL Holding

Catalog excerpts

PELLET MILLS COMPOUND FEED INDUSTRY

Open the catalog to page 1

AMANDUS KAHL ACCOMPANIES YOU on your way to the right decision AMANDUS KAHL has been manufacturing flat die pellet mills since the mid-1920s and can look back on around 100 years of expertise in the design and manufacture of pellet mills for various industries. Worldwide, the flat die pellet mill 39 – 1000 is one of the most successful pellet mills on the market. AMANDUS KAHL pellet mills are characterised by sophisticated technology and quality “Made in Germany”. The machine repertoire for the compound feed sector currently comprises more than 10 types of pellet mills with different sizes...

Open the catalog to page 2

COMPOUND FEED PELLETS Co ntact info @ akahl.de For controlled dosing of nutrients and to promote animal health in cattle, poultry and pigs. Main fields of application of pelleting Poultry feed pellets The requirements of feed pellets for different animal species differ in terms of length, diameter and composition. KAHL flat die pellet mills can be used to produce pellets for poultry, cattle and pig feeding. KAHL pellet mills are designed for universal use for a wide range of products differing in terms of structure, bulk density, binding strength and particle size. Horse feed pellets Calf...

Open the catalog to page 3

Co ntact info @ akahl.de A quick die change enables the production of differently shaped products Even rabbits benefit from the special shapes In addition to the typical cylindrical pellets, special shapes for example for horse, cattle and rabbit feeding can also be produced on KAHL pellet mills. Likewise, dog or cat treats can be produced with low investment costs. The robust dies and maximum production flexibility reflect AMANDUS KAHL’s high quality standards. For more variety: Go for pellet shapes such as cloverleaves or square pellets Dogfood Horse feed

Open the catalog to page 4

PAN GRINDER ROLLERS AND DIES Depending on the field of application, different hardening processes are required, all of which are carried out in KAHL’s own hardening shop for pan grinder roller and die production ADVANTAGES OF KAHL FLAT DIES Advantages offered by the machine High robustness Long service life and low wear Low consumption of operating materials Low lubricant requirement Low operating costs Fast and easy die change Low space requirement and footprint Low noise Large pelleting chamber for products with low bulk density Large pan grinder rollers with low circumferential speed...

Open the catalog to page 5

Co ntact info @ akahl.de PELLET MILLS Compound feed industry Die diameter mm Roller diameter/width mm Type Die diameter mm Roller diameter/width mm Type Die diameter mm Roller diameter/width mm Type Die diameter mm Roller diameter/width mm Hook height approx. 2435 1635 Number of rollers Roller speed m/s Hook height approx. 2170 1480 Hook height approx. 2280 1480 Hook height approx. 2365 Hook height approx. 2520 1720 Hook height approx. 2005 2005 213

Open the catalog to page 6

Compound feed industry Number of rollers Roller speed m/s Drive motor kW/min-1 Feeding hopper Secure and encrypted connection Dosing screw EAPR cabinet with graphic touch panel Mixing screw Pellet mill Hook height approx. 3300 3000 KAHL service team / online service Electronic automatic pellet mill regulation (EAPR) Hook height approx. 3300 2565 Co ntact info @ akahl.de EAPR Touch Panel Do you have questions regarding the KAHL technology? We will be happy to answer them and can be reached here: info@akahl.de +49 (0)40 727 71-0 akahl.com Optimum pellet mill operation Low manpower...

Open the catalog to page 7

Co ntact info @ akahl.de Pelleting plants for feedstuff 1 Compound feed plant: throughput capacity up to 210,000 t/a Dosing screw Mixing conditioner Pellet mill Belt cooler Learn more about our compound feed plant in Egypt (throughput capacity up to 300,000 t/a) Scan the QR code now Compound feed plant: throughput capacity up to 245,000 t/a

Open the catalog to page 8

Visit our online shop shop.akahl.de AMANDUS KAHL GmbH & Co. KG Dieselstrasse 5 – 9 21465 Reinbek Germany Directly to the online shop: Scan the QR code now

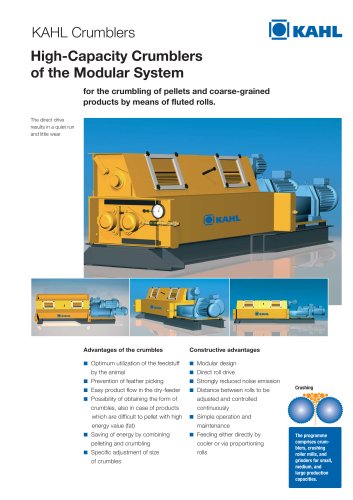

Open the catalog to page 9All AMANDUS KAHL catalogs and technical brochures

-

PELLET MILLS

9 Pages

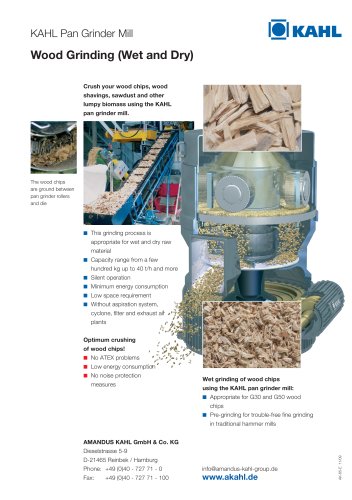

-

Wood Pelleting Plants

12 Pages

-

AK01 KAHL ROTOSPRAY®

2 Pages

-

KAHL High-Speed Mixer SMW

2 Pages

-

KAHL Annular gap expander

4 Pages

-

KAHL AKANA Hammer Mills

2 Pages

-

KAHL Press O-500/390

2 Pages

-

KAHL Continuous Mixer

2 Pages

-

KAHL Batch Mixers

2 Pages

-

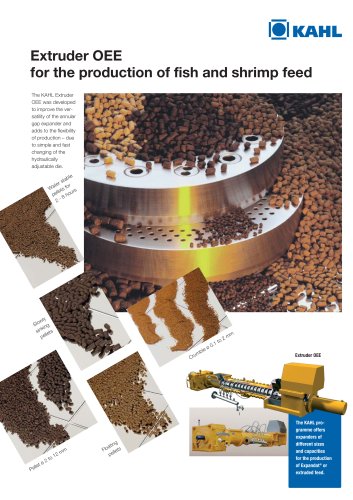

Crown Expander OEK

2 Pages

-

Belt driers and coolers

8 Pages

-

Pelleting Presses

8 Pages

-

Annular Gap Expander

4 Pages

-

KAHL Fabric Belt Drier

4 Pages

-

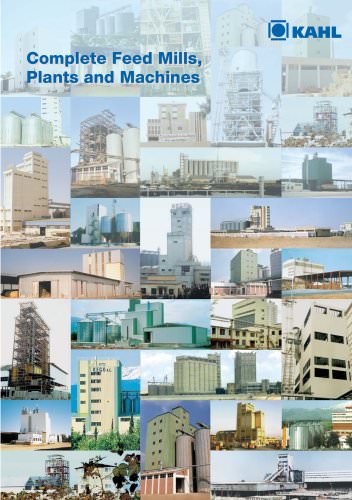

Feedmills, Plants, and Machines

12 Pages

Archived catalogs

-

Waste Tyre Recycling Plants

6 Pages