Website:

AMANDUS KAHL

Website:

AMANDUS KAHL

Group: KAHL Holding

Catalog excerpts

Complete Feed Mills, Plants and MachinesComplete Feed Mills, Plants and Machines >

Open the catalog to page 1

AMANDUS KAHL GmbH & Co. KGThe delivery programme: F. H. SCHULE MUEHLENBAU GmbHNEUHAUS NEOTEC GmbH and AMANDUS KAHL HAMBURG was founded in 1876and today looks back on more than 125 years of machine and plant construction. In 1920, the first pelleting press designed as a worm extruder was supplied. Since 1948 the manufacturing programme has been continuously extended and in 1991 the KAHL Group was founded. Today, the members of the KAHL Group are: Process technology, engineering, machines, plants, turn-key feedmills, worldwide subsidiaries and agencies as well as after-sales service. Plants:...

Open the catalog to page 2

Page 4 > Continuous mixer, short time conditioner,batch mixer, continuous cellular wheel weigherCrushing roller mill, crumbler Annular gap expander flexibility of production KAHL Extruder OEE Flat die pelleting press,pellet hardness testerRotospray Page 5 Page 6 Page 7 Page 8 Page 9 > ֮ process,belt driers/coolersIndividual conditioning systems for hygienictreatment, Verticone mycotoxin treatment, hydrothermal treatment using the reactorEcology in the compound feed plant,ecoprocessorProcess control withESEP and EAPR Page 10 Page 11 Page 12 3 >

Open the catalog to page 3

Continuous mixer (molasses mixer) Short time conditioner MK Batch mixers MAH and BWM > ■ Temperature 50-95 C > Т֠ Temperature 50-95 C > Т֠ Mixers of the construction series MAH and BWM are discontinu- ous mixers > ■ Retention time 10-30 seconds > ■ Retention time 10-60 seconds > ■ Liquid addition up to 30 % > ■ Liquid addition up to 6 % > ■ Conditioning with steam and water > ■ Conditioning with steam and water > ■ They are used as individual machines or as batch mixers within a plant > ■ High speed > ■ Low speed > ■ 2-3 kWh/t energy input > ■ 1-2 kWh/t energy input > ■ Liquid addition is...

Open the catalog to page 4

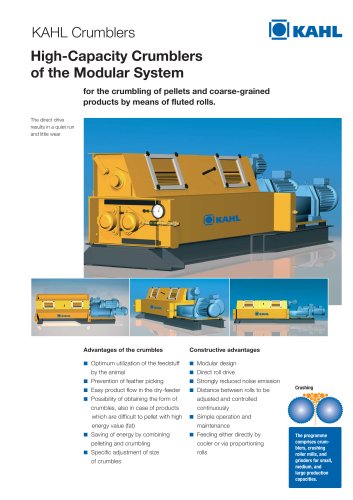

The KAHL crushing roller mill replaces traditional size reduction systems in the compound feed plant > Crushing roller mill 1000 > ■ Narrow particle size distribution (spectrum) > ■ Structure corresponds to the animals requirements > Ң֠ Particularly appropriate for granular products > ■ Modification of the structure during operation > ■ No aspiration required > ■ Low noise emission < 70 dBA > ■ No heat generation in the product being ground > ■ No moisture loss > ■ Up to 50 % energy savings > Crushing roller millwith 2 sections Crushing roller mill 1000 For the crumbling of pellets...

Open the catalog to page 5

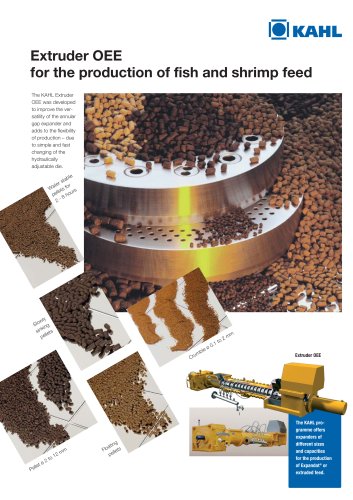

The KAHL Extruder is designed with a hydraulically adjustable die. Thus blockages are avoided. Together with the 10 minutes conditioner starting and stopping are possible almost without residues. > ■ Fast die change without special tools > ■ Double-walled tubular case for cooling and heating. > Extruder OEE Unlike traditionalextruders, the KAHL extruder OEE is equipped with a hydraulically adjustable die. Thus product and toolchange is considerably facilitated and accelerated. During starting and stopping of the plant, there are hardly any product losses.

Open the catalog to page 7

The new presstype 14-175 for the production of smallest capacities.Design: Jens Plewa,Hamburg ■ > Press manufacturingdepartment at AMANDUS KAHL, hall 4Pelleting presstype 39-1000 for high capacities Pellet hardness tester,manual individual test

Open the catalog to page 8

■ Exhaust air temperature reduced by 25 % > ■ Emission of odours reduced by 50 % > Eco-processor > ■ 30 % product heating by means of recirculation of heat > ■ Due to a 50 % steam reduction CO > 2 is also reduced by 50 % > ■ Smaller steam generator > Recirculation of heat ■ Lower water consumption due to a 50 % reduction of steam > ■ No formation of condensate > ■ Low dust emission Steam >

Open the catalog to page 11

ESEP , the E lectrical control S ystem of the E x P ander, and the EAPR ,the E lectrical A utomaticsystem for PR esses, have been developed by the company KAHL. > Modem/internetHMI MPI bus Process field bus DP, ASI bus Control roomKAHL serviceteam ■ Full automation of the complete production line > ■ Constant product quality at a high throughput rate > ■ Low manpower requirements > ■ Up to 3 lines on a PC > ■ Better monitoring of the production process > ■ High availability due to the use of proven quality components > ■ High process flexibility, adjustable and extendible without any...

Open the catalog to page 12All AMANDUS KAHL catalogs and technical brochures

-

PELLET MILLS

9 Pages

-

Wood Pelleting Plants

12 Pages

-

AK01 KAHL ROTOSPRAY®

2 Pages

-

KAHL High-Speed Mixer SMW

2 Pages

-

KAHL Annular gap expander

4 Pages

-

KAHL AKANA Hammer Mills

2 Pages

-

KAHL Press O-500/390

2 Pages

-

KAHL Continuous Mixer

2 Pages

-

KAHL Batch Mixers

2 Pages

-

Crown Expander OEK

2 Pages

-

Belt driers and coolers

8 Pages

-

Pelleting Presses

8 Pages

-

Annular Gap Expander

4 Pages

-

KAHL Fabric Belt Drier

4 Pages

Archived catalogs

-

Waste Tyre Recycling Plants

6 Pages