Catalog excerpts

Dimensional drawing ♦Model 3: Robot, positioner table, and robot carriage Specifications, appearance, and equipment are subject lo chango without notice for further improvement Be sure to read the manual carefully before use. • Dedicated partitions are required for hazard-free operation of the system. • the system requires 1.07 pm wavelength barriers. ■•'The specifications described in this catalogue are for the Japanese domestic market This laser product uses a Class 4 invisible laser for processing and a Class 3R visible laser for positioning. Class 4 invisible laser: Avoid eye or skin exposure to direct or scattered radiation. Never look into the radiation nor touch it. Class 3R visible laser: Avoid direct eye exposure. AMADA CO., LTD. All Rights Reserved.

Open the catalog to page 1

Multi-functional, high speed, and high grade welding Amada Fiber Laser Welding system achieves high speed and high grade welding that is impossible with conventional laser welding. Amada provides the solutions to customer's issues by Fiber laser oscillator, Amada's original processing head, various software and features to assist you with the complete welding process and enhance your laser welding productivity. Fiber laser welding system Fiber laser welding system(FLW) 'FLW is the acronym for fiber laser welding. Proposal of integrated processing from 3D CAD/CAM to welding Product...

Open the catalog to page 2

high speed, and high grade welding | What is a fiber laser? O Welding performance improvement of highly reflective or difficult-to-weld materials A fiber laser is short in wavelength with high beam absorption against metals. This means that the fiber laser is able to weld aluminium, copper, and many other highly reflective or difficult-to- weld materials thereby expanding your process range. © Realization of high grade processing by smooth continuous welding Continuous waveform (CW) welding produces highly airtight, smooth welds. NC auto focus control enables a wide range of processing from...

Open the catalog to page 3

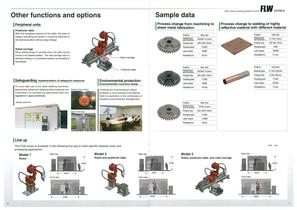

Other functions and options Sample data Process change from machining to sheet metal fabrication Positioner table With the workpiece placed on the table, the axes of rotation and tilting are driven to move the weld line to the desired position without setup change. Robot carriage When welding large or complex parts, the robot can be moved to the desired position. The robot carriage helps to eliminate working in a constrained position and handling of | Safeguarding Implementation of safeguard measures For your safe use of our laser welding machines, appropriate equipment safeguarding...

Open the catalog to page 4All AMADA SA catalogs and technical brochures

-

RBR series

3 Pages

-

FLW ENSIS

2 Pages

-

HRB series

4 Pages

-

AML 2515AJ

8 Pages

-

BREVIS 121AJ

4 Pages

-

HFE 3i 5012

4 Pages

-

HG ATC Series

8 Pages

-

HFE M2 Series

8 Pages

-

HFE M2 5012

4 Pages

-

TK-3015EU

2 Pages

-

EG 4010

4 Pages

-

HG 1003 ARs

8 Pages

-

EG 6013 AR

8 Pages

-

AS LUL

2 Pages

-

EML 2515 AJ

4 Pages

-

ACIES Series

8 Pages

-

Bending Tools

96 Pages

-

EM ZRT Series

8 Pages

-

Fabrivision

4 Pages

-

HG Rm

8 Pages

-

LC F1 NT

8 Pages

-

GS II/ GX II

2 Pages

-

LC Alpha IV

8 Pages

-

HFE-M2

8 Pages

-

TURRET PUNCH PRESS TOOLING

72 Pages

-

NEX 2

16 Pages

-

LCG AJ

8 Pages

-

ENSIS AJ

8 Pages

-

LC C1 AJ

8 Pages

-

FO MII NT

8 Pages

-

QUATTRO

8 Pages

-

FLC AJ

8 Pages

-

LCG

8 Pages

-

HG SERIES

8 Pages

-

HG ATC

8 Pages

-

HG ARs

4 Pages

-

HFE 3i SERIES

8 Pages

-

FOL AJ

8 Pages

-

EM-MII

4 Pages

-

EM-ZR SERIES

8 Pages

-

AE-NT

8 Pages

-

FMB Electric press brake

2 Pages