Website:

Alzmetall

Website:

Alzmetall

Catalog excerpts

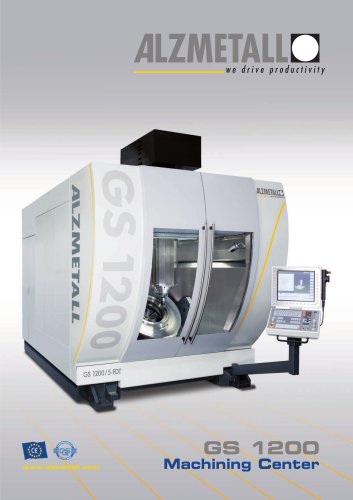

Machining Center

Open the catalog to page 1

ALZMETALL - COMPANY INTRODUCTION Premises is a company with an international reputation and global activities. For more than six decades we have been the leader in technology for drilling, milling and casting. Alzmetall products have proven themselves in general machining applications, in the automotive industry, in mould and die business, at the aircraft industry, as well as in many mid-size mechanical engineering enterprises. Our experience is based on over 198.000 machines supplied. We focus on precision, performance and Quality for all our products. With our own foundry we do not only...

Open the catalog to page 2

Machining Center with options: chip conveyor, cooling unit, coolant filter and mist extraction unit. These options are either to be installed along the right - or left side of the Machining Center. Highlights • Alzmetall Specific Gantry Concept (ASGK) • Grey Cast Iron and Spheroidal Graphite Cast Iron Machine Body and Frame components • Travel-System-Carriage with incorporated Box-in-BoxSystem - patented • 4-fold Linear Guidance for Travel-System-Carriage and Z-Axis with integrated Motor-Spindle • 3-fold Torque-Drives for Swivel-Axis (A-Axis) and Rotary-Axis (C-Axis) •...

Open the catalog to page 3

RESEARCH AND DEVELOPMENT Development by using Finite-Elements-Method (FEM) Z X FEM generated Structural Model - Point of force-input at TCP and simultaneously at Machine-Table Development The „Finite-Elements-Method“ was applied to obtain the desired static and dynamic characteristics of each individual part of the machine and to investigate the collective rigidity of the Machining Center. Multi-Elements-Simulation During the development process the Finite-Elements-Method was already applied by building the structure of the machine, patterned from the 3D-Volume–Model born from CAD to...

Open the catalog to page 5

BASIC DESIGN „Think Big“ when Milling and Turning Extreme rigid, Integral-Basic-Body prepared to be fitted with: • Frame Side Walls as carrier for both Y-Axes (Y- and V-Axis) • NC – Swivel- and Rotary-Table (A- and C- Axis) • Tool-Magazines (ATC) All statically stressed Basic-Machine-Parts made from EN-GJL 300 (GG 30) and all dynamically stressed Basic-Machine-Parts and components made from EN-GJS 500 (GG

Open the catalog to page 6

ALZMETAL - SPECIFIC GANTRY - CONCEPT (ASGK) – patented – 4-fold internal Linear Guidance Systems ALZMETALL- S p e c i f i c Gantry-Concept ( ASGK ) F Frame Side Wall In comparison to conventional and modified Gantry-Designs: ➠➠Deviation (Deflection) reduced by factor 2.3 delivers ➠➠Rigidity increased by factor 2.3 versus “On-Topmounted” Linear Guidance Systems ➠➠Less Position Deviation at TCP at the same level of Acceleration ➠➠Significant increase of Cutting-Tool lifetime 2 On-Top-mounted Linear Guidance Systems F Frame Side Wall l Conventional and modified Gantry-Designs • 2...

Open the catalog to page 7

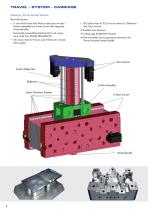

TRAVEL - SYSTEM - CARRIAGE Design Characteristics Box-in-Box-System: • Y- and V-Axis Frame Side Walls as static basic structure. Therein embedded two X-Axes-Carrier with integrated Z-Axis Monobloc • Dynamically stressed Basic-Machine-Parts and components made from EN-GJS 500 (GGG 50) • All 3 Linear-Axes (X/Y/Z) are each 8-fold and in 2 levels linear guided • All 3 Linear-Axes (X/Y/Z) are each driven by 2 Ballscrews and 2 Servo-Drives ➠➠Excellent Axes dynamics ➠➠Cutting edge Parallel-Path-Precision ➠➠Thermal stability due to geometrical symmetry with Thermo-Symmetric Motor-Spindle...

Open the catalog to page 8

NC - SWIVEL - AND ROTARY - TABLE (SDK) Swivel- (A-Axis) and Rotary- (C-Axis) Unit • Direct Rotary Drives (Torque-Motors) for high dynamic and oscillating Machining – maintenance free – • 2 internal Torque-Motors at each Frame side wall as NC-Swivel-Axis (A-Axis) – patented• NC-Rotary-Table (C-Axis) equipped with Torque-Motor ➠➠Highest swivel and rotational speed ➠➠Higher accuracies – no mechanical backlash ➠➠Elimination of friction at Drive-Components ➠➠Wear – and maintenance free delivers reduced Total Cost of Ownership (TCO) over lifetime period of Machining Center

Open the catalog to page 9

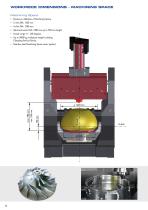

WORKPIECE DIMENSIONS - MACHINING SPACE Machining Space • Maximum utilization of Machining Space • C-Axis DIA. 1420 mm • A-Axis DIA. 1380 mm • Spherical sector DIA. 1380 mm up to 700 mm height • Swivel range +/- 140 degrees • Up to 3000 kg workpiece weight including Clamping-Set-Up-Device • Stainless steel Machining Space cover (option)

Open the catalog to page 10

OPTIONS NC-Swivel (A-Axis) -and Rotary-Table (C-Axis) Clamping surface mm Further executions on demand 1) 2) NPS = Zero Point Tooling Syst

Open the catalog to page 11

CNC - C o n t r o l s Heidenhain iTNC 530 HSCI (standard) Heidenhain TNC 640 (in prep.) KINEMATIK Gauging Accuracy check and compensation - KinematicsOpt., Heidenhain - C 996, Siemens Electrical Handwheels - HR 410, Heidenhain - HR 520, Heidenhain - Mini-Handwheel, Siemens 3 D -To u c h P r o b e s Infrared transmission - TS 640, Heidenhain - TS 740, Heidenhain - IRP 25.41, m&h Inprocess - OMP 60, Renishaw - TC 50, Blum Multiple-Media-Coupling for Rotary-Table 4-fold on selection air and/or fluids

Open the catalog to page 12

Tool Setting System Laser System for Tool Setting and Breakage Detection on selection including mechanical Touch Trigger Probes LTS 35.65, m&h, (without mech. Touch Trigger Probes) LC NT, Blum, (without mech. Touch Trigger Probes) TC 76, Blum, (with mech. Touch Trigger Probes) Camera and Screen Camera mounted at Machining Space with transmission to external flat screen or Video-Server for process-set-ups and process-controls Tool-Magazines Single Chain Magazine 75 Tool positions Double Chain Magazine 150 Tool positions Rack-Type Magazines over 150 Tool positions on request Production...

Open the catalog to page 13

Mist Extraction Unit Attached to Machine-Basic-Body Remote Diagnosis, Remote Maintenance and for NC-Programming-Support Machining Center Acceptance Workpiece according to ALZMETALL-Standard, on selection Customer-Workpiece (option) Services NC-Program-Training, Operator-Training for Heidenhain and Siemens Services Machining Center Installation, Set-Up, Production Assistance and Maintenance [ ] Options • Rotary-Table (C-Axis) various configurations • Mutiple-Media-Coupling for Rotary-Table (C-Axis) • Motor-Spindles RPM-Range 18.000 RPM/24.000 RPM • Tool-Magazines up to 150 Tool positions •...

Open the catalog to page 14Archived catalogs

-

DRILLING MACHINES

38 Pages

-

GS 1200

20 Pages