Catalog excerpts

L1.0406 • L1.0506 L1.0706 • L1.0807 • Connection up to M60 x 2 • Nominal flow rate up to 850 l/min

Open the catalog to page 1

Application Ventilation of tanks for hydraulic and lubrication systems, and gearboxes. General The oil levels in the tanks of hydraulic systems are subject to continuous variation due to temperature changes and the operation of cylinders and pressure vessels. In order to prevent over pressure in the tanks, an exchange of air with the external atmosphere is necessary. By the use of a ventilating filter, the outside air that is drawn in is filtered and the ingress of dust is therefore prevented. Special features The ventilation openings are designed that dust on the surface of the tank is not...

Open the catalog to page 2

Ap-curves for complete filters in Selection Chart, column 2 Dx The abbreviations represent the following p-values resp. finenesses: 2 CL =2 pm Composite 99,5 % efficiency for particles of size 2 pm tested in a single pass test with ISO MTD For special applications, finenesses differing from these curves are also available by using special composed filter media.

Open the catalog to page 3

Remarks: • The ventilating filters listed in this chart are standard filters. If modifications are required, e.g., with integrated dipstick, we kindly ask for your request. • Ventilating filters in Vandalism Proof design see catalogue sheet 50.20.

Open the catalog to page 4

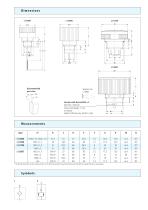

Recommended port sizes Measurements Type * The thread dimensions do not exactly conform to the DIN ISO standard thread (functioning with the DIN ISO standard thread is guaranteed)

Open the catalog to page 5

Layout Sizes The determining factor for selecting the size is the maximum over / under pressure allowed in the container. For versions without double check valves, the initial pressure drop with a clean air filter should not exceed 0,03 bar. For versions with double check valves, the initial pressure drop for air IN with a clean air filter should not exceed 0,1 bar. Filter fineness In the ideal case, the fineness of the ventilating filter matches the fineness of the system filter (see also CETOP RP 98 H). By the use of filter fineness 2 CL the ingress of dust into the tank is effectively reduced....

Open the catalog to page 6

· Connection up to M42 x 2 · Nominal flow rate up to 850 l/min

Open the catalog to page 7

Description Application Ventilation of tanks for hydraulic and lubrication systems, and gearboxes. General The oil levels in the tanks of hydraulic systems are subject to continuous variation due to temperature changes and the operation of cylinders and pressure vessels. In order to prevent over pressure in the tanks, an exchange of air with the external atmosphere is necessary. By the use of a ventilating filter, the outside air that is drawn in is filtered and the ingress of dust is therefore prevented. Special features The ventilation openings are designed that dust on the surface of the...

Open the catalog to page 8

Diagrams ∆p-curves for complete filters in Selection Chart, column 3 Pressure drop as a function of the flow volume air IN / OUT Pressure drop as a function of the flow volume air OUT Pressure drop as a function of the flow volume air IN Filter fineness curves in Selection Chart, column 4 Filtration ratio β as a function of particle size x tested in a single pass test with ISO MTD The abbreviations represent the following β-values resp. finenesses: Filtration ratio β for particles > x µm 2 CL = 2 µm Composite 99,5 % efficiency for particles of size 2 µm tested in a single pass test with ISO MTD...

Open the catalog to page 9

Selection Chart Dx UT L1 L2 L3 N gr. ir I ir O ment ment ment dia e e a ure a te see ve r re re re se ra p r ssu ss asu asu easu ess ce /cu nA ro ow pre g pre k me k me m l fl re d m D finen surfa tio k l t ng n ec na stic ipstic ipstic ymbo cki racki nn er mi ressu iagra ilter igh Co P Dip D F No Filt D d S Cra C We . no with spanner SW 47 with spanner SW 47 with spanner SW 47 with spanner SW 47 with Easy Lock Pin with Easy Lock Pin with Easy Lock Pin with Easy Lock Pin with Easy Lock Pin with Easy Lock Pin with Easy Lock Pin with Easy Lock Pin Remarks: • The ventilating filters listed in...

Open the catalog to page 10

(Easy Lock Pin, supplied with L1.0809) Version with thread M42 x 2 eye R2,5 / hole ø2 fixing chain (length 17 cm) on request ARGO-HYTOS Part No. S0.0512.1302 Spanner size (special wrench, supplied with L1.0808) Recommended port sizes Measurements Type * The thread dimensions do not exactly conform to the DIN ISO standard thread (functioning with the DIN ISO standard thread is guaranteed)

Open the catalog to page 11

Layout Sizes The determining factor for selecting the size is the maximum over / under pressure allowed in the container. For versions without double check valves, the initial pressure drop with a clean air filter should not exceed 0,03 bar. For versions with double check valves, the initial pressure drop for air IN with a clean air filter should not exceed 0,1 bar. Filter fineness In the ideal case, the fineness of the ventilating filter matches the fineness of the system filter (see also CETOP RP 98 H). By the use of filter fineness 2 CL the ingress of dust into the tank is effectively reduced....

Open the catalog to page 12

· With filling filter · 6 hole flange · Nominal flow rate up to 850 l/min

Open the catalog to page 13

Description Application Filling / ventilation of tanks for hydraulic and lubrication systems as well as gearboxes. Design Filling filter: Ventilating filter: General The oil levels in the tanks of hydraulic systems are subject to continuous variation due to temperature changes and the operation of cylinders and pressure vessels. In order to prevent over pressure in the tanks, an exchange of air with the external atmosphere is necessary. By the use of a ventilating filter, the outside air that is drawn in is filtered and the ingress of dust is therefor prevented. A combined filling filter prevents...

Open the catalog to page 14

Diagrams ∆p-curves for complete filters in Selection Chart, column 2 Pressure drop as a function of the flow volume Air IN/OUT Pressure drop as a function of the flow volume Air OUT Pressure drop as a function of the flow volume Air IN Filter fineness curves in Selection Chart, column 5 Filtration ratio β as a function of particle size x tested in a single pass test with ISO MTD The abbreviations represent the following β-values resp. finenesses: Filtration ratio β for particles > x µm 2 CL = 2 µm Composite 99,5 % efficiency for particles of size 2 µm tested in a single pass test with ISO MTD...

Open the catalog to page 15All Altantek Hidrolik Pazarlama ve Tic. A.S. catalogs and technical brochures

-

BD2 + R24

30 Pages

-

Hydraulic orbit motor & Accessories

147 Pages

-

GPL009

76 Pages

-

Steering units

7 Pages

-

HPLDF

7 Pages

-

GPG009

25 Pages

-

M4MF

27 Pages

-

MINING Fittings

73 Pages

-

FITTINGS

3 Pages

-

MINING Hoses

41 Pages

-

DRILLING

14 Pages

-

Pin Prick Tool

1 Pages

-

Nipple Inserter

1 Pages

-

Hydroforming

1 Pages

-

Marking Machines

1 Pages

-

Cleaning Machines

1 Pages

-

UNIFLEX

22 Pages

-

Hose Skiving Machines

2 Pages

-

HOSES

30 Pages

-

ALTAN ÜRÜN KATALOĞU

55 Pages

-

ALUMINIUM HEAT EXCHANGERS

42 Pages

-

CRIMPED FITTINGS

138 Pages

-

HOSE PROTECTIONS

20 Pages