Catalog excerpts

Hydraulic orbit motors & Accessories

Open the catalog to page 1

The operating principle of the motors is based on an internal gear design, consisting of a stator and rotor through which the output torque and speed are transmitted. The distributor valve is driven synchronously by the rotor through a cardan shaft ensuring that each one of the chambers of the motor are filled and emptied precisely. SPOOL VALVE -The distributor valve has been integrated with the output shaft. The valve has hydrodynamic bearings, and has infinite life when load ratings are not exceeded. OM, OP, OPL, OR, ORL and OH motors have a Spool Valve. DISC VALVE's function is to...

Open the catalog to page 3

HYDRAULIC MOTORS OM APPLICATION » Conveyors; » Textile machines; » Mining machinery; » Machine tools; » Ventilators; » Construction plant equipment and access platforms etc. OPTIONS » Model - Spool valve, gerotor; » With or without flange; » Side and rear ports; » Series with pressure valve(s) » Shafts - straight and splined; » Metric and BSPP ports; » Other special features. | Int OMP Series with Integrated Internal Crossover Relief Valve A—► B, Ap= 100 bar (50 bar) OMP Series with Integrated Internal Crossover Relief Valve A, Ap = 100 bar (50 bar) OMD Series with Integrated Internal...

Open the catalog to page 4

* Intermittent operation: the permissible values may occur for max. 10% of every minute. ** Peak load: the permissible values may occur for max. 1% of every minute. *** For speeds of 30 RPM or lower, consult factory or your regional manager. 1. Intermittent speed and intermittent pressure drop must not occur simultaneously. 2. Recommended filtration is per ISO cleanliness code 20/16. A nominal filtration of 25 micron or better. 3. Recommend using a premium quality, anti-wear type mineral based hydraulic oil HLP(DIN51524) or HM (ISO 6743/4). If using synthetic fluids consult the factory for...

Open the catalog to page 5

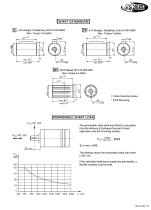

|FUNCTION DIAGRAMS luM \A.b ^ The function diagrams data was collected at back pressure 5-5-10 bar and oil with viscosity of 32 mm2/s at 50° C.

Open the catalog to page 6

[FUNCTION DIAGRAMS The function diagrams data was collected at back pressure 5-5-10 bar and oil with viscosity of 32 mm2/s at 50° C.

Open the catalog to page 7

|FUNCTION DIAGRAMS roivrso The function diagrams data was collected at back pressure 5-5-10 bar and oil with viscosity of 32 mm2/s at 50° C.

Open the catalog to page 8

Three Bolts Mount [^- Oval Mount (2 Holes) C : 3xM6-12mm depth P(A B|:2xG3/8 or (M18x1,5)-12mm depth T :G1/8 or (MlOxl)-IOmm depth Standard Rotation Viewed from Shaft End Port A Pressurized - CW Port B Pressurized - CCW Reverse Rotation Viewed from Shaft End Port A Pressurized - CCW Port B Pressurized - CW

Open the catalog to page 9

[c]- 0I6 straight, Parallel key 5x5x16 DIN 6885 Max. Torque 3,9 daNm V- Motor Mounting Surface * ForF Mounting [PERMISSIBLE SHAFT LOAD The permissible radial shaft load [Prad] is calculated from the distance [L] between the point of load application and the mounting surface:

Open the catalog to page 10

Meta Hydraulic is introducing hydraulic motor with a new generation of speed sensor. The electric output signal is a standard voltage signal that can be used for regulating the speed of a motor. The speed is measured by a sensor in accordance with the Hall principle. Signal processing and amplification are performed in the sensor housing. Aconnection is provided in the housing by a Plug connector Ml 2 Series. Thisperformanceisapplicableforallmotorsof OM series.Themaintechnicalfeatures correspond to the standard motors series OM.

Open the catalog to page 11

[Technical data] ^Output signal] Frequency range Output Power supply Current input Current load Ambient Temperature Protection Plug connector Mounting principle Pulses per revolution Load max.:lhigh=llow<50mA No load current, max: 20 mA [Wiring diagram] /imax (=50mA)

Open the catalog to page 12

I Pos. 1 [■ fAdjustmentOption^ omit - without valve - Side ports with single crossover relief valve > - Side ports with dual crossover relief valve Pos.2[ [Mounting-Flange-omit - Tree bolts mount -Oval mount, two holes Pos.3[ [Port type (not valid for P and D version)) omit - Rear ports - Side ports Pos. 5|-[Shaft Extensions* - p16 straight Parallel key 5x5x16 DIN 6885 - p16 straight Parallel key 5x5x16 DIN 6885 with corrosion resistant bushing - 014 straight, Parallel key 5x5x16 DIN 6885 SH |- 016,5 splined, B17x14 DIN 5482 Line to controled^ ■ B-»A (left running) A-»B (right running)...

Open the catalog to page 13

APPLICATION » Conveyors; » Feeding mechanism of robots and manipulators; » Metal working machines; » Textile machines; » Machines for agriculture; » Food industries; » Grass cutting machinery etc. » Model- Spool valve, gerotor; » Flange and wheel mount; » Motor with needle bearing » Side and rear ports; » Shafts- straight, splined and tapered; » Shaft seal for high and low pressure; » Metric and BSPP ports; » Other special features. foil flow in drain linel Ap f Pressure Losses^

Open the catalog to page 14

* Intermittent operation: the permissible values may occur for max. 10% of every minute. ** Peak load: the permissible values may occur for max. 1% of every minute. *** For speeds of 10 RPM or lower, consult factory or your regional manager. 1. Intermittent speed and intermittent pressure drop must not occur simultaneously. 2. Recommended filtration is per ISO cleanliness code 20/16. A nominal filtration of 25 micron or better. 3. Recommended using a premium quality, anti-wear type mineral based hydraulic oil HLP(DIN51524) or HM (ISO 6743/4). If using synthetic fluids consult the factory...

Open the catalog to page 15

* Intermittent operation: the permissible values may occur for max. 10% of every minute. ** Peak load: the permissible values may occur for max. 1% of every minute. *** For speeds of 10 RPM or lower, consult factory or your regional manager. 1. Intermittent speed and intermittent pressure drop must not occur simultaneously. 2. Recommended filtration is per ISO cleanliness code 20/16. A nominal filtration of 25 micron or better. 3. Recommended using a premium quality, anti-wear type mineral based hydraulic oil HLP(DIN51524) or HM (ISO 6743/4). If using synthetic fluids consult the factory...

Open the catalog to page 16All Altantek Hidrolik Pazarlama ve Tic. A.S. catalogs and technical brochures

-

BD2 + R24

30 Pages

-

GPL009

76 Pages

-

Steering units

7 Pages

-

HPLDF

7 Pages

-

GPG009

25 Pages

-

M4MF

27 Pages

-

MINING Fittings

73 Pages

-

FITTINGS

3 Pages

-

MINING Hoses

41 Pages

-

DRILLING

14 Pages

-

Pin Prick Tool

1 Pages

-

Nipple Inserter

1 Pages

-

Hydroforming

1 Pages

-

Marking Machines

1 Pages

-

Cleaning Machines

1 Pages

-

UNIFLEX

22 Pages

-

Hose Skiving Machines

2 Pages

-

HOSES

30 Pages

-

ALTAN ÜRÜN KATALOĞU

55 Pages

-

ALUMINIUM HEAT EXCHANGERS

42 Pages

-

CRIMPED FITTINGS

138 Pages

-

HOSE PROTECTIONS

20 Pages