Website:

Alpha Moisture Systems Ltd

Website:

Alpha Moisture Systems Ltd

Group: HALMA

Catalog excerpts

Model SADPmini2-Ex Dewpoint Hygrometer 2297 SADPmini2-Ex User Manual

Open the catalog to page 1

Contact Information Head Office Alpha Moisture Systems Alpha House 96 City Road Bradford West Yorkshire BD8 8ES United Kingdom Tel: +44 (0) 1274 733100 Email: info@amsystems.co.uk Website: amsystems.co.uk Office Opening Hours: Monday - Thursday 8.30am - 5.30pm (UK TIME) Friday 8.30am - 5.00pm Saturday and Sunday - Closed Authorised Distributor Contact Information © Alpha Moisture Systems 2017-2023

Open the catalog to page 2

Introduction This User Manual is only for use with the instrument supplied. All information required for the safe and proper operational use of the instrument is contained here. Make sure you read and understand the information and instructions in the User Manual before using the instrument. Failure to operate the instrument as directed in this User Manual may: • Impair the inbuilt safety protection offered by the instrument • Expose personnel to risk of injury • Cause damage to and/or impair the function of the instrument • Invalidate the instrument warranty Explanation of Prohibition,...

Open the catalog to page 6

Instrument Description The SADPmini2-Ex is a fully self-contained, micro-controller based, battery operated dewpoint hygrometer primarily used for mobile analysis and short term continuous monitoring. Using an ultra-high capacitance aluminium oxide sensor and a high accuracy, high speed, Analogue to Digital Converter (ADC), the SADPmini2-Ex monitors dry industrial process gas and dry compressed air samples. Results are displayed on a colour Liquid Crystal Display. The SADPmini2-Ex is controlled via the Navigation Keypad. The display screen has two sections: • A primary, upper section ①...

Open the catalog to page 7

General Arrangement

Open the catalog to page 8

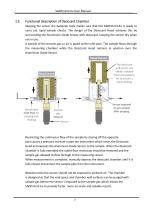

Functional Description of Desiccant Chamber Keeping the sensor dry between tests makes sure that the SADPmini2-Ex is ready to carry out rapid sample checks. The design of the Desiccant Head achieves this by surrounding the Aluminium Oxide Sensor with desiccant, keeping the sensor dry when not in use. A sample of the process gas or air is piped to the inlet port. The sample flows through the measuring chamber while the Desiccant Head remains in position over the Aluminium Oxide Sensor. Restricting the continuous flow of the sample by closing off the opposite port causes a pressure increase...

Open the catalog to page 9

Important Information 2.1 Bluetooth Certification 2 NOTE Bluetooth is a wireless technology standard for exchanging data over short distances from fixed and mobile devices. The SADPmini2-Ex uses a Bluetooth connection facility to allow data transfer to either a PC or a Bluetooth printer WT41 has modular certification with certification number R 209-J00047/J00231. This instrument complies with FCC radiation exposure limits - Contains FCC ID:QOQWT41/QOQWT41u. This device complies with Industry Canada licence-exempt RSS standard(s) - Contains IC: 5123A-BGTWT41/5123A-BGTWT41u. WT41 meets the...

Open the catalog to page 10

SADPmini2-Ex User Manual It is the responsibility of the user to ascertain the suitability of the SADPmini2-Ex for use in hazardous areas. Risk assessments should be carried out prior to use, taking into account the SADPmini2-Ex certifications, location and the gas being monitored. Symbols Table Symbol Description Lithium-ion Battery The SADPmini2-Ex is powered by a single lithium-ion battery. Only use the USB power supply supplied with the instrument to charge the battery. It is recommended that the SADPmini2-Ex be put on charge overnight prior to use Pressure Exposure The telescopic...

Open the catalog to page 11

Battery Information The SADPmini2-Ex uses a single lithium-ion battery (3.65 V nominal). The battery cannot be removed or replaced by the user. The instrument must be returned to an authorised agent for battery replacement. When the battery charge is low and/ or the battery is charging, the instrument display will be dimmed. If the battery is very low and the user tries to turn the instrument on, a battery low message will be displayed and the instrument will shut down. DO NOT Do not replace the battery. Only authorised agents should replace the battery. Do not open, crush, expose to heat...

Open the catalog to page 12

NOTE Authorised distributor details will differ locally

Open the catalog to page 13

Installation This section details the sample specific SADPmini2-Ex installation procedures and the instructions for obtaining the correct result from sample gas. 3.1 Gases to avoid Corrosive Gases: The Sensor should not be exposed to corrosive gases (or corrosive contaminants in the gas sample) as these can chemically attack the sensor, impairing calibration accuracy and/or damaging it beyond economic repair. Examples of such gases are mercury (Hg), ammonia (NH3), chlorine (Cl2) etc. Strong oxidising agents such as ozone (O3) should also be prevented from coming into contact with the sensor.

Open the catalog to page 14

Gas Sampling System DO NOT Do not allow the sample pressure to exceed 0.3 bar / 4 psi above ambient NOTE To maintain sample integrity and minimise equilibration time the system should be as simple as possible and of minimum swept volume. NOTE The sample tube should be stainless steel for very dry gas applications. If any section of the pipework must be flexible, it is recommended that PTFE is used. Installation Configurations The installation configurations discussed cover the following sample scenarios: • Clean gas < 10 bar • Clean gas > 10 bar • Particulate or liquid contamination No. 1 2...

Open the catalog to page 15

Clean Gas < 10 Bar Reduce positive pressure gas to atmospheric pressure. Use a needle valve at low pressures (<10 barg) to control flow and pressure drop. Clean Gas > 10 Bar Reduce positive pressure gas to atmospheric pressure. Use a stainless steel, low swept volume pressure regulator at higher pressures (>10 barg). Particulate/ Liquid Contamination Filter all particulate matter. Use a coalescing filter (with drain) for liquid condensate samples. Hygroscopic particulates and liquid condensate will slow the achievement of equilibrium and delay the final result. Hygroscopic liquid (such as...

Open the catalog to page 16

Install the sample piping system and equipment as per the required installation configuration. NOTE: The SADPmini2-Ex is not connected to the inlet piping system at this stage. Open the sample Isolation Valve and adjust the needle valve/ regulator to allow a flow of 5-15 litres per minute to atmosphere through to sample pipe. Allow the gas to flow through the sample pipe for 2 minutes to purge the system. After ensuring that the sample gas is clean and dry connect the sample pipe to the instrument. NOTE: The orientation of the ports is not important. When the sample flow is low or very dry...

Open the catalog to page 17All Alpha Moisture Systems Ltd catalogs and technical brochures

-

Model 6020 User Manual

41 Pages

-

SADPmini2 User Manual

57 Pages

-

AMT User Manual

14 Pages

-

AMT-Ex User Manual

15 Pages

-

PSS User Manual

17 Pages

-

DS1200-Exd-AMT-Ex

3 Pages

-

DS1500-Exd

2 Pages

-

DS4000-Exd-AMT-Ex

3 Pages

-

DSP-FCI Portable Hygrometer

3 Pages

-

Model 6020 Exd

4 Pages

-

Model 6020

3 Pages

-

DS1500

3 Pages

-

SADPmini2 Comparison Chart

1 Pages