Catalog excerpts

1 ® Air-operated Diaphragm Pumps made of Plastic E-Series State of the Art: registered Community Design NO. 001 096 291

Open the catalog to page 1

® Since its foundation in 1984, ALMATEC Maschinenbau GmbH has kept on defi ning the current state of the art of air operated diaphragm pumps via decent product characteristics. 1984 Series AD (Multicor) The compact and “closed” design of this pumps has immediately become the ALMATEC trademark. Its massive plastic construction provided the mass an oscillating pump requires. The housing material used for wetted parts have been either abrasion-resistant polyethylene or the chemically almost universally resistant PTFE. The outer surface was completely metal-free. Diaphragms with integrated...

Open the catalog to page 2

® THE E-SERIES AT A GLANCE • air-operated diaphragm pumps in solid design • housing made of PE or PTFE, both also available in a conductive version • interchangeability to the A-Series • seven sizes from DN 8 to DN 80 • max. capacities of 0.9 to 48 m3/h • increased pump security due to innovative ring-tightening structure • compared to the A-Series, increased capacity and decreased air consumption thanks to the optimized fl ow pattern, decreased noise level • ATEX conformity • exterior free of metal • optimized diaphragm fi xing • different possible port confi gurations • ball or cylinder...

Open the catalog to page 3

4 The ALMATEC E-Series is based on the functional principle of double diaphragm pumps. The basic confi guration consists of two external side housing with a center housing between them. Each of the side housings contains a product chamber which is separated from the center housing by a diaphragm. The two diaphragms are interconnected by a piston rod. Directed by an air control system, they are alternately subjected to compressed air so that they move back and forth. In the fi rst fi gure, the compressed air has forced the left-hand diaphragm towards the product chamber and displaced the...

Open the catalog to page 4

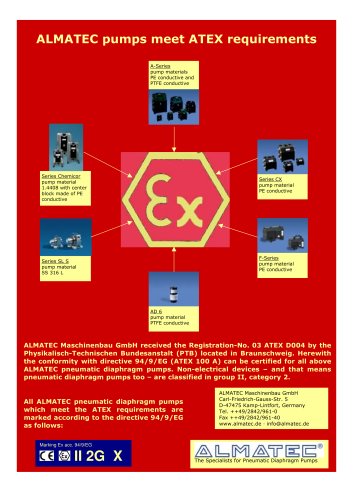

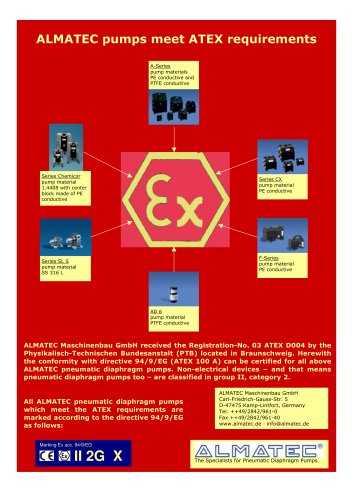

5 CONDUCTIVE VERSIONS FOR EXPLOSION-PROOF AREAS (ATEX CONFORMITY) The housings and internals of the conductive versions are made of PE or PTFE fi lled with conductive pigment which always remains below the limits set by the FDA. The pumps are to be grounded via a connection on the center housing, thus excluding the risk of electrostatic charges. Conductive pumps of the E-Series are ATEX conform. They can consequently be used without diffi culty in gas and dust atmospheres and for infl ammable liquids. MORE SPECIAL FEATURES ALMATEC air-operated diaphragm pumps of the E-Series consist of only...

Open the catalog to page 5

6 The metal-free, pneumatically pilot-operated PERSWING P® air control system ensures accurate reversal of the main piston and is characterized by low noise levels. Only two moving parts ensure that there is absolutely no dead center. It does not require maintenance, operates without any lubrication whatsoever and is made up of no more than four different parts. The complete cartridge can be replaced easily. The patented PERSWING P® is a precision control system and therefore requires clean, oil-free compressed air to ensure its optimal function. Ball valves are robust and insensitive to...

Open the catalog to page 6

7 Barrier chamber system (code B) The ALMATEC barrier chamber system for sizes E 10 to E 50 meets high safety requirements. The individual diaphragm is replaced by two diaphragms arranged in tandem with a barrier chamber of conductive PE between them and fi lled with non-conductive liquid. The barrier chambers must always be fi lled entirely to transmit the air pressure to the medium. Therefore it is monitored by a level sensor. If the diaphragm on the product side breaks, medium merely enters the barrier chamber and the non-conductive liquid fl ows into the medium. The change in...

Open the catalog to page 7

8 A lot of industrial applications need not only stationary air-operated diaphragm pumps but also mobile pumping units (e. g. as emergency pump, as short-dated replacement for a pump to be repaired or for decanting between two containers). The transport cart consists of a square-pipe frame made of stainless steel and four fi xable conductive castors. Room is available for product and air hoses. Possible accessories are: complete air supply with clamp connection, regulator with integrated fi lter and air-distributor for pump and damper. TRANSPORT CART TECHNICAL DATA Pump size E 08 E 10 E 15...

Open the catalog to page 8

9 The capacity specifi ed in the pump performance charts generally refers to water (1 mPa·s). The value must be reduced correspondingly when pumping media with higher viscosity. The design capacity can be read off directly from the graph and the corresponding pump size selected. The example shown here is based on a required capacity of 10 m3/h with a product viscosity of 6000 mPa·s. The dash-dotted line intersects the design capacity scale at 17 m3/h. When handling viscous media, the highly increased necessary suction capacity has to be taken into consideration also. A suffi cient size of...

Open the catalog to page 9

11 The pump size E 80 extends the E-Series range to seven sizes. With a maximum capacity of 48 m3/h the E 80 is proper for an effi cient circulation of great quantities. Housing material is PE. The housing bolts are not tighten against a ring. The using of spring washers allows a high security and less leakage liability. Further features of the A 80 at a glance: • air control system: in spite of high performance one piece only less spare parts and low noise level • icing: big muffl er for reduced risk of icing • product connections: fl ange connection DN 80 high stability and leakage...

Open the catalog to page 11

AL-003, 07.2009, Subject to change without notice The Specialists for Air Operated Diaphragm Pumps ALMATEC Maschinenbau GmbH Carl-Friedrich-Gauss-Str. 5 · 47475 Kamp-Lintfort, Germany Telephone ++49.2842.961-0 · Telefax ++49.2842.961-40 info@almatec.de · www.almatec.de ®

Open the catalog to page 12All ALMATEC Maschinenbau GmbH catalogs and technical brochures

-

C- Serie

8 Pages

-

FUTUR Series

8 Pages

-

CXM Series Brochure A4

6 Pages

-

C-Series Brochure A4

6 Pages

-

Chemicor Brochure A4

8 Pages

-

Biocor Brochure A4

8 Pages

-

AHD/AHS Series Brochure A4

8 Pages

-

E-Series AODD Pumps

12 Pages

-

Almatec brochure

16 Pages

-

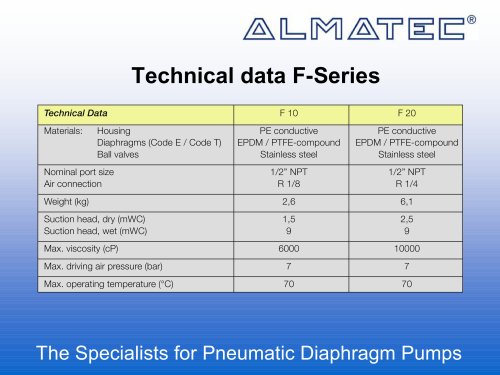

F-SERIES

16 Pages

-

CX

12 Pages

-

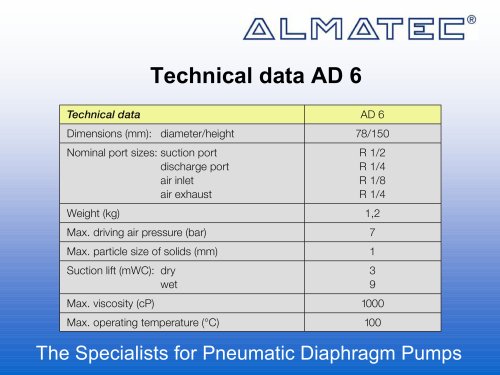

AD 6

8 Pages

-

AH

20 Pages

-

FUTUR

20 Pages

-

CHEMICOR

20 Pages

-

A-SERIE

28 Pages

-

Pumps for low to medium duty

1 Pages

-

Decontamination-Sheet

1 Pages

Archived catalogs

-

Almatec Market Brochure

8 Pages