Catalog excerpts

BIOCOR SERIES Where Innovation Flows METAL AIR-OPERATED DOUBLE-DIAPHRAGM PUMPS FOR STERILE APPLICATIONS WITHIN PHARMACEUTICAL, BIOTECHNICAL AND FOOD INDUSTRY

Open the catalog to page 1

BIOCOR the Aseptic Pump at a Glance • Air operated pumps for sterile applications within pharmaceutical, biotechnical and food industry • Built in accordance to the essential specifications (EHEDG, FDA, CLASS VI etc.) • Integrated cleaning-system with high cleaning results • CIP (clean in place) and SIP (sterilization in place) capabilities • ATEX conformity • Wetted materials made of SS316L (Basel Standard II) to < 0.4 pm (15.75 pin) • Sterile design: no horizontal areas • Drainage of the pump by magnetical lifting of the valve balls from the outside (B20 and B32 only) • Smooth diaphragms...

Open the catalog to page 2

Functional Principal The ALMATEC BIOCOR Series is based on the functional principle of air-operated double-diaphragm pumps. The basic configuration consists of two external product housings with a center block between them. Each of the product housings contains a product chamber which is separated from the center block by a diaphragm. The two diaphragms are interconnected by a piston rod. Directed by an air control system, they are alternately subjected to compressed air so that they move back and forth. In the first figure, the compressed air has forced the left-hand diaphragm towards the...

Open the catalog to page 3

More Special Features Always a demand for sterile applications: all housing parts of the BIOCOR pumps show no horizontal areas. Each pump of the B 20 an B 32 sizes comes with four ball lifting magnets, which can be attached to the pump housing from the outside at the location of the four ball valves. The ball valves are risen up magnetically out of their seats and the pump is drained entirely without having to be dismounted. There are no mechanical ball lifters with parts and seals in the wetted area. Soft redirections without rotating parts and shaft seals in the product chamber together...

Open the catalog to page 4

Diaphragm Monitoring (code D) A capacitive sensor installed in the pump muffler detects all liquids and in case of a diaphragm rupture it outputs a corresponding signal to a controller which then triggers an alarm or disconnects the pump via a connected solenoid valve. Barrier Chamber System (code BS) The ALMATEC barrier chamber system meets further safety requirements. The individual diaphragm is replaced by two diaphragms arranged in tandem with a barrier chamber filled with non-conductive liquid. The barrier chambers must always be completely filled so the driving air pressure can be...

Open the catalog to page 5

Dimension (mm/inch): length Weight (kg/lbs) Max. particle size of solids (mm/inch) Suction lift, dry (mWC/ftWC) Suction lift, wet (mWC/ftWC) Max. driving and operating pressure (bar/psig) Max. operating temperature (°C/°F) Nominal port size (depends of the choosen suction and discharge connection) Air connection, BSP REQUIRED CAPACITY m³/hr DESIGN CAPACITY L/min m³/hr Viscosity Of The Liquid in °E (referred to a specific gravity of 1) Pump Capacity The capacity specified in the pump performance charts generally refer to water (1 mPa·s). The value must be reduced correspondingly when pumping...

Open the catalog to page 6

Performance Charts The following data refer to water at 20°C / 68°F (referring to DIN EN ISO 9906) PSIG 100 90 Total head Pump with barrier chamber Pump capacity Total head BIOCOR 32 Air pressure bar Air consumption Nm3/min Pump capacity Total head BIOCOR 40 Air pressure bar Air consumption Nm3/min Pump capacity

Open the catalog to page 7

Where Innovation Flows PSG® reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 10-2018 ALMATEC Maschinenbau GmbH Hochstraße 150-152 47228 Duisburg, Germany Tel: +49 (2065) 89205-0 Fax: +49 (2065) 89205-40 info@almatec.de almatec.de Copyright © 2018 PSG®, a Dover company

Open the catalog to page 8All ALMATEC Maschinenbau GmbH catalogs and technical brochures

-

C- Serie

8 Pages

-

FUTUR Series

8 Pages

-

CXM Series Brochure A4

6 Pages

-

C-Series Brochure A4

6 Pages

-

Chemicor Brochure A4

8 Pages

-

AHD/AHS Series Brochure A4

8 Pages

-

E-Series AODD Pumps

12 Pages

-

Almatec brochure

16 Pages

-

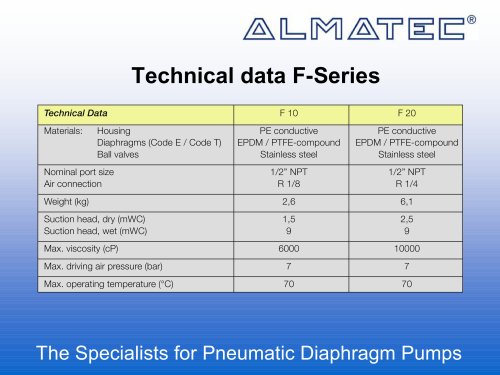

F-SERIES

16 Pages

-

CX

12 Pages

-

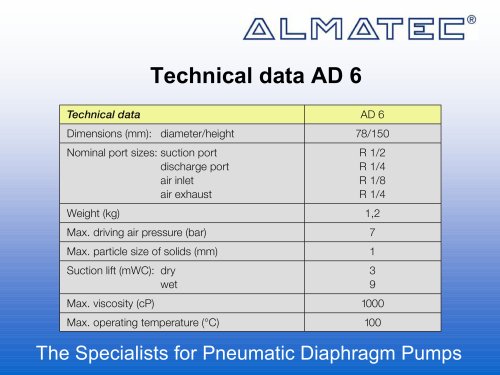

AD 6

8 Pages

-

AH

20 Pages

-

FUTUR

20 Pages

-

CHEMICOR

20 Pages

-

A-SERIE

28 Pages

-

E-SERIES

12 Pages

-

Pumps for low to medium duty

1 Pages

-

Decontamination-Sheet

1 Pages

Archived catalogs

-

Almatec Market Brochure

8 Pages