Catalog excerpts

AHD/AHS SERIES Air-Operated Double-Diaphragm Pumps Where Innovation Flows HIGH PRESSURE DIAPHRAGM PUMPS MADE OF PLASTIC AND STAINLESS STEEL AIR-OPERATED DOUBLE-DIAPHRAGM PUMPS CONSTRUCTED OF POYETHYLENE FOR HIGH-PRESSURE APPLICATIONS UP TO 15 BAR (218 PSIG)

Open the catalog to page 1

Two Pump Series–One Result AHD internal Series Pump with pressure booster Pump without internal pressure booster The two sizes of the AHS series feature an extremely rugged available in three sizes with housing that is suitable for higher discharge pressures. used for every application under heavy load conditions, from low psig), they can build up discharge pressures variable up to high pressure applications up yields a ratio of drive pressure/ ratio of drive pressure/discharge pressure discharge pressure of more than 1:2. The the corresponding air pressure has to be supplied, typical...

Open the catalog to page 2

AHD & AHS Series at a Glance Features & Benefits • Air-operated double-diaphragm pumps designed for a discharge pressure up to 15 bar (218 psig) • AHD Series (“D“ stands for Duplex) with internal pressure booster • AHS Series (“S“ stands for Simplex) without internal pressure booster, for using with an external booster • Corrosion-proof and wear-resistant housing in solid design made of polyethylene for heavy-duty applications • Double-acting principle of operation • Gentle displacement by compressible drive medium • Maximum capacities of 4, 10 and 20 m³/h (17, 44 and 87 gpm) for AHD pumps...

Open the catalog to page 3

Special Development for Filter Press Feeding In many industrial processes, substances occur in aqueous muddy form, where the liquid portion must be removed. This can be in production processes, for example in the filtration of edible oils or yeast solutions, but more frequently at the end of a process in waste sludge from various industries from surface finishes to wastewater treatment. The disposal of such sludge is frequently done by compression and drying in a filter press. The AHD Series has been specially developed for feeding filter presses with chemical waste and special sludge. With...

Open the catalog to page 4

Wear Resistant Housing Material & Solid Design All wetted housing parts are made of ultra-high-molecular-weight low pressure polyethylene (PE UHMW) in heavy solid design. PE competes with PP (polypropylene) which is frequently used in the manufacture of pumps. Thermally and chemically speaking, there are virtually no differences between these two. However, the similarity ends where the mechanical properties are concerned: trials based on the sand-slurry method have shown that the abrasion resistance of the PE (upper material sample) is 7 times higher than that of PP (middle material sample)...

Open the catalog to page 5

Spare part kits S for pumps of the AHD/AHS series are compiled for single-shift operation (8 hours per day). These kits ensure that the correct replacement parts are always available in the required quantities. This helps to avoid production stoppages and ensures that the Almatec pumps are always ready for action. Besides, it is cheaper to buy spare parts as a kit than individually. The standard configuration of the suction and discharge ports are according to the illustration: Discharge port to the top, suction port forward. Pump size Dimensions: Width Depth Height Flange connections Air...

Open the catalog to page 6

Performance Range The following data refer to water at 20°C (68°F) (referring DIN EN ISO 9906). The blue lines state the air consumption in Nm³/min. PSIG mWC Total Head Total Head Total Head 8.8 Flow Rate Flow Rate Flow Rate Total Head Total Head Total Head 22 Flow Rate Flow Rate Flow Rate Flow Rate Flow Rate 17.6 AHS 25 AHS 25 with External Booster AHS 25 with External Booster Flow Rate Flow Rate TotalTotal Head Head Head Total Total Head Total Head Total Head TotalTotal Head Head Head Total Flow Rate TotalTotal Head Head Head Total with External Booster Flow Rate 0 8.8 17.6 26.4 35.2 44...

Open the catalog to page 7

Where Innovation Flows PSG® reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 10-2018 ALMATEC Maschinenbau GmbH Hochstraße 150-152 47228 Duisburg, Germany Tel: +49 (2065) 89205-0 Fax: +49 (2065) 89205-40 info@almatec.de almatec.de Copyright © 2018 PSG®, a Dover company

Open the catalog to page 8All ALMATEC Maschinenbau GmbH catalogs and technical brochures

-

C- Serie

8 Pages

-

FUTUR Series

8 Pages

-

CXM Series Brochure A4

6 Pages

-

C-Series Brochure A4

6 Pages

-

Chemicor Brochure A4

8 Pages

-

Biocor Brochure A4

8 Pages

-

E-Series AODD Pumps

12 Pages

-

Almatec brochure

16 Pages

-

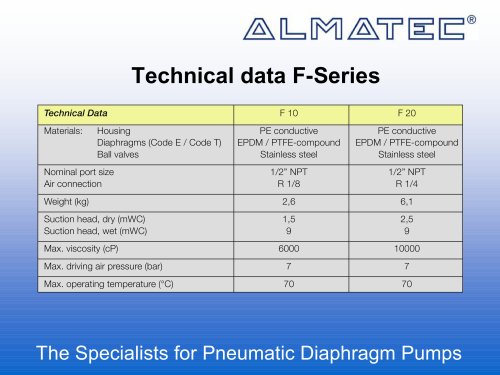

F-SERIES

16 Pages

-

CX

12 Pages

-

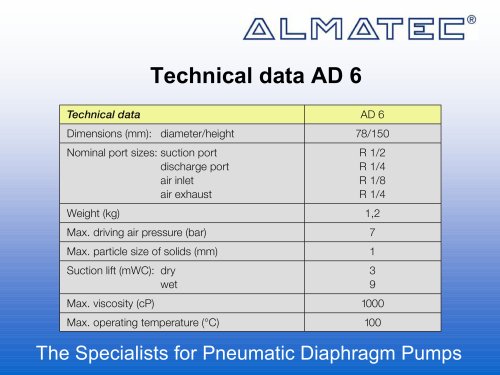

AD 6

8 Pages

-

AH

20 Pages

-

FUTUR

20 Pages

-

CHEMICOR

20 Pages

-

A-SERIE

28 Pages

-

E-SERIES

12 Pages

-

Pumps for low to medium duty

1 Pages

-

Decontamination-Sheet

1 Pages

Archived catalogs

-

Almatec Market Brochure

8 Pages