Catalog excerpts

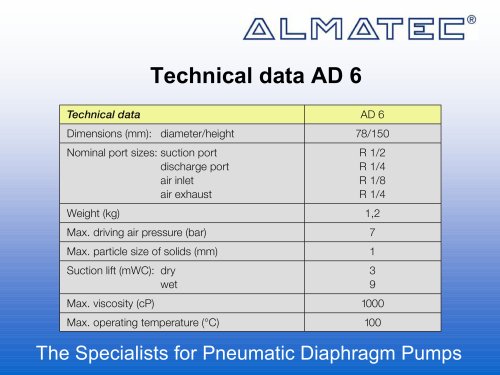

ALMATEC Air-Operated Diaphragm Pumps AD 6 Operating and Installation Instructions ought to be studied before installing the pump Original Instruction Introduction ALMATEC air-operated diaphragm pumps are constructed according to the state of the art and they are reliable. Imminent danger by operating error or misuse can lead to damages of properties and/or persons. The pumps are to be applied for the intended use and in a safety-related proper condition only. Each person working on the ALMATEC air-operated diaphragm pumps concerning installation, start-up, handling or maintenance has to read this manual completely and in an attentive way and has to follow all mentioned procedures and safety notes. General description of the machine, appropriate use and residual dangers AD 6 pumps are oscillating positive displacement pumps and are based on the functional principle of double diaphragm pumps. Both product chambers are sealed to one side by a diaphragm, which are interconnected by a piston rod. Directed by an air control system, the diaphragms are alternately loaded with compressed air so that they move back and forth. When the compressed air has forced one diaphragm towards the product chamber and displaced the liquid from that chamber, liquid is simultaneously drawn in by the other diaphragm, thus refilling the second product chamber. When the end of the stroke is reached, it reverses automatically and the cycle is repeated in the opposite direction. The appropriate use of an Almatec air-operated diaphragm pump refers to the liquid transport taking into account the operation parameter mentioned in this manual and in compliance of the given terms for commissioning, operation, assembly, disassembly and maintenance. Even if all necessary safety measures described in this manual have been met, a residual danger exists by leakages or mechanical damages. At sealing areas or connections liquid can be released uncontrollably then. The ALMATEC Maschinenbau GmbH is certified as a modern, quality-orientated enterprise according to DIN EN ISO 9001:2008 and 14001:2005. Before release for dispatch, any pump has to undergo an extended final control. As a general rule in the countries of the EU only such machines are allowed to take into operation, which are determined to meet the regulations of the EU machinery directive, the harmonized standards, European standards and the respective national standards. Hence the operator has to verify whether the ALMATEC pump manufactured and delivered properly according to the customers order meets the mentioned requirements. Therefore make sure, before putting the pump into operation, that the pump and the used materials of construction are suitable for the provided application and the installation site. All housing parts, diaphragms and valves exposed to the medium are made of PTFE-TFM (housing nut made of PVDF). Storage In general the ALMATEC pump is delivered operational and packaged. If the unit is not installed right away, proper storage conditions are important for a trouble free operation later. The pump has to be protected from wetness, coldness, dirtying, UV-radiation and mechanical influences. The following storage conditions are recommended: - Steady ventilated, dust and vibration free storage room - Ambient temperature between 15°C and 25°C with a relative humidity below 65% - Prevention of direct thermal influences (sun, heating) 1

Open the catalog to page 1

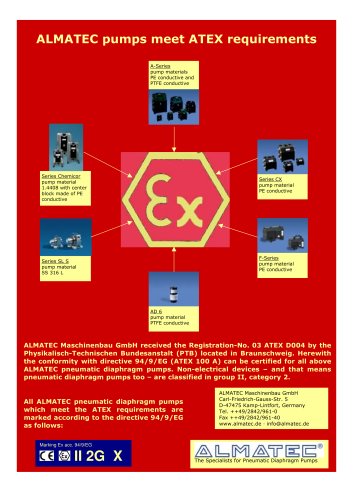

Operation in explosion-proof areas and for inflammable liquids (Reg.-No. PTB: 03 ATEX D004) For inflammable liquids as well as for applications in explosion-proof areas, only pumps with housings and fittings in conductive plastic materials may be used. The AD 6 with the housing material PTFE-conductive meets this requirement. With the exception of being used as submersible pump, the AD 6 has to be grounded. All housing parts are connected, therefore it is not necessary to ground single parts. ALMATEC pumps made of electrically conductive PTFE are suitable to be used in explosion areas of...

Open the catalog to page 2

Installation and operation The four available connection points are identified by letters: S = suction port, D = discharge port, Z = air inlet and A = air exhaust. Two different connection kits are available as accessories. The "connection kit, sampling" comprises an inlet strainer for the suction port and hose connections for air inlet, air exhaust and discharge port. The "connection kit, laboratory" comprises hose connections for suction port, discharge port and air inlet. In general, the pump has to be connected load free. Neglecting this causes leakage and maybe even damages. Before...

Open the catalog to page 3

„h In case of a diaphragm rupture, it might be possible fort he fluid pumped to intrude into the air side of the pump. In very adverse conditions - e.g. pressure within the fluid system during stopped air supply - the fluid might as well find its way into the air supply lines. To protect other devices like pulsation dampers or even pneumatic valves, it is recommended to protect the air supply line accordingly, e.g. via a non-return valve. This would as well avoid polluting the air supply line. „h If the product tends to settle, the pump has to be equipped with the optional inlet strainer....

Open the catalog to page 4

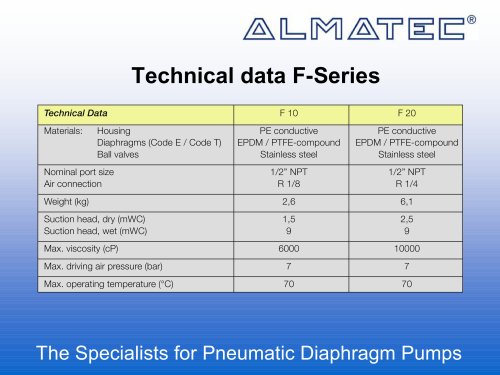

Additional temperature hints The temperature and pressure limitations listed on page 2 are solely based on mechanical temperature limits of the housing material used. Depending on the fluid pumped, the maximum safe operating temperature of the housing material can be reduced significantly. A general aspect of lower temperatures is, that below 0°C cold-brittling of the elastomers used within the pumps can results in accelerated wear. Regarding the housing materials, please note that PTFE keeps mechanically stable as well for an extended temperature range. However the temperature limit of...

Open the catalog to page 5

Spare parts list Item Piece Description Material Part number 1 1 Front housing PTFE-TFM conductive 1 06 010 65 2 1 Rear housing PTFE-TFM conductive 1 06 011 65 3 2 O-ring, product channel Kalrez® 9 06 614 79 4 4 Check valve PTFE-TFM 1 06 013 69 5 2 Plug PTFE 1 06 017 60 6 1 Lock pin PVDF 1 06 016 50 7 1 Housing nut PVDF 1 06 012 50 8 2 O-ring, housing nut FKM 9 65 616 74 9 1 Shaft PETP 1 06 230 84 10 2 Diaphragm PTFE-TFM 1 06 031 69 11 2 O-ring, diaphragm TFA/Silicon 9 35 615 63 12 6 O-ring, end caps NBR 9 36 504 71 13 2 End cap, cpl. PETP 1 06 251 84 14 1 Main piston, cpl. PETP 1 06 254 84...

Open the catalog to page 6All ALMATEC Maschinenbau GmbH catalogs and technical brochures

-

C- Serie

8 Pages

-

FUTUR Series

8 Pages

-

CXM Series Brochure A4

6 Pages

-

C-Series Brochure A4

6 Pages

-

Chemicor Brochure A4

8 Pages

-

Biocor Brochure A4

8 Pages

-

AHD/AHS Series Brochure A4

8 Pages

-

E-Series AODD Pumps

12 Pages

-

Almatec brochure

16 Pages

-

F-SERIES

16 Pages

-

CX

12 Pages

-

AH

20 Pages

-

FUTUR

20 Pages

-

CHEMICOR

20 Pages

-

A-SERIE

28 Pages

-

E-SERIES

12 Pages

-

Pumps for low to medium duty

1 Pages

-

Decontamination-Sheet

1 Pages

Archived catalogs

-

Almatec Market Brochure

8 Pages