Website:

ALLGAIER PROCESS TECHNOLOGY

Website:

ALLGAIER PROCESS TECHNOLOGY

Group: SIEBTECHNIK TEMA Group

Catalog excerpts

PROCESS TECHNOLOGY Dr.-Ing. Mathias Trojosky Head of drying technology department ALLGAIER PROCESS TECHNOLOGY GmbH Uhingen System users frequently have to decide whether to use a drum dryer (rotary dryer) or a fluidised-bed dryer (vibratory dryer). While the application areas of these two types of dryers overlap to a certain degree, there are various selection criteria which favour one or the other for a given application. It can often be difficult to make the right choice. This also applies to the users of drying systems. Each supplier of such systems naturally advertises the technology of his product range as the best, and the users are faced with the problem of deciding which system is really the best for the intended application. This article could perhaps help to solve the problem. Drum dryers have been used for decades for drying many different types of goods and are widely used in the building, minerals and raw-materials industry. Fluidised-bed dryers, on the other hand, are widely used in the manufacture of chemicals, foodstuffs and pharmaceuticals. Various special applications, such as spray-granulation dryers, suspension and paste dryers, fluidised-bed dryers/coolers with heat exchangers integrated into the fluidised bed, have been developed for fluidised-bed dryers. In the last twenty years fluidised-bed dryers have also been installed in the building-material and minerals industry. At the same time, however, drum dryers have been improved further and permit energy-efficient applications, particularly in the minerals industry, and very robust and hard-wearing solutions.

Open the catalog to page 1

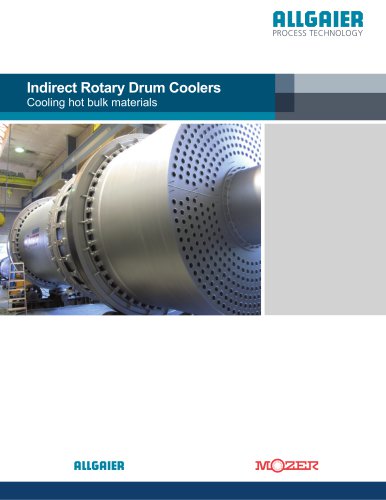

Drum dryers: energy-efficient and particularly robust In drum dryers, the material to be dried is moved by the rotation of the drum and by the effects of vanes and blades mounted inside the drum. In the past, drum dryers were in most cases constructed with a slight downward inclination in order to support the movement of the material. Today, the drums are almost always mounted horizontally. Lifting blades lift the moist material from the base of the drum and then allow it to fall, thus ensuring good contact between the moist material and the hot air. In most drying applications, the...

Open the catalog to page 2

Fluidised-bed dryers: efficient drying of products with uniform Fluidised-bed dryer for drying sand, limestone and marble Saving energy during drying In cases where the material to be dried has to be cooled immediately, the use of a double-shell dryer for drying and cooling in a single unit is recommended. In such dryers, the material is dried in the inner tube of the drum. The dry and warm material then flows from the inner tube into the outer shell, where it is moved in the opposite direction by suitably designed vanes and blades and is cooled by the incoming, cold ambient air. With the...

Open the catalog to page 3

ALLGAIEAPROCESS TECHNOLOGY Competent advice guarantees optimal solutions In general, the air distribution plates should be designed with a sufficiently high pressure loss in order to ensure good distribution of the drying air over the complete area of the dryer. The fans for the drying air must therefore generate a high pressure. Otherwise, the air will take the path of least resistance through the material to be dried and this will result in a poor flow of air, particularly in places where the material is moist. For this reason, fluidised-bed dryers have a higher specific consumption of...

Open the catalog to page 4All ALLGAIER PROCESS TECHNOLOGY catalogs and technical brochures

-

Vibration-Round-Screener VRS

3 Pages

-

Dry cleaning of stone

3 Pages

Archived catalogs

-

Contact Disc Dryer CDry

20 Pages

-

Pharmatical process

6 Pages

-

Allgaier Process Technology

16 Pages