Website:

ALLGAIER PROCESS TECHNOLOGY

Website:

ALLGAIER PROCESS TECHNOLOGY

Group: SIEBTECHNIK TEMA Group

Catalog excerpts

Rotary drums and fluidized bed dryers add quality to your process

Open the catalog to page 1

Agro Chemicals Fertilizers Recycling Waste materials Inorganic sludges Filter cakes Iron sulphate Titanium dioxide Hydroxides Limestone Magnesite Magnetite Metal chips Wood chips Gypsum Ore Ilmenite Slag Potash Salts Dolomite Fly ash Coke Anthracite Talc Steel shot Bone grist Fodder Cocoa nibs Rice Allgaier drum and fluidized bed dryers make processes more productive Today, Allgaier dryers are used successfully in almost all industrial sectors. Particularly in the mineral processing industry but also in the chemical and fertilizer industry and in recycling operations, the rotary drum dryers...

Open the catalog to page 2

Features • High thermal efficiency • Few parts subject to wear • Product-optimized drying • Large number of process options • Easy access and thus easier replacement of spare parts • Variable design for different products For every requirement Regardless of whether a single unit or a complete system is needed - Allgaier can meet every requirement. With complete solutions, including engineering, installation and commissioning, Allgaier proves their competence in the area of plant construction.

Open the catalog to page 3

Drum dryers, System MOZER® Single-shell, double-shell and triple-shell drums Allgaier rotary drum dryers are used, particularly in the minerals industry, for drying free flowing but also sticky and abrasive wet materials. The design ensures high performance in a small space. Special versions also permit the use of combined processes. Their main features are high throughput rates and the ability to process solid materials with widely differing granulometric properties. Allgaier outside – MOZER® inside The drum dryers are available in single-shell, double-shell and triple-shell versions. The...

Open the catalog to page 4

Combined processes Allgaier has extended and perfected the use of drum dryers. The result of this work is a range of designs for new combined processes in a single system which are therefore very effective and economical. A technical highlight is the double-shell drum dryer system TK and it‘s even more efficient sytem TK+, which dries and cools the sand in a single step. The TK+ system is feeding part of the wet product, referred to as the “bypassing product”, directly into the outer drum. There it is mixed with the dry and warm product from the inner drum which dries the wet bypassing...

Open the catalog to page 5

With screening unit. This system dries and screens many types of materials with reasonably good separation (aluminium scrap, shredded recycling products, ...). There is thus a reduced need for separate downstream screening steps. With cleaning zone. This system replaces separate washing steps especially for lime stone aggregates or increases the amount of good material from dry separation. This system produces granules from powders and cakes, such as of fertilizers, lime, bentonite and clay. It can also be used for coating applications (urea, potash granules). Municipal waste or paper...

Open the catalog to page 6

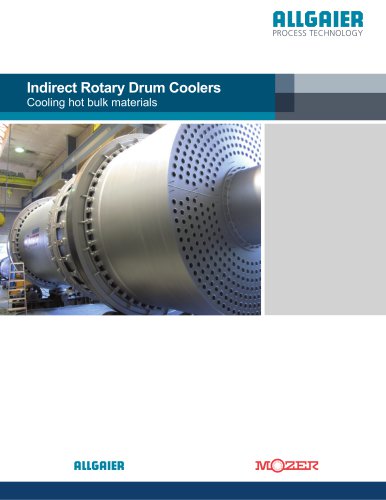

System RK/KT-R Two different systems of indirect rotary drum coolers for hot and very hot bulk materials (titanium dioxide, slag, hydroxides, gypsum) with heat recovery from the hot products. Drum dryers can be combined with static water-cooled sand coolers to achieve uniformly low outlet temperatures, regardless of the ambient temperature.

Open the catalog to page 7

Fluidized bed dryers and coolers Allgaier fluidized bed dryers can be used advantageously for the treatment of many material substances, such as sand, limestone and ceramics and also for pellets and granules, mineral fertilizers, salt and fine chemicals. The high rate of heat transfer in the fluidized bed ensures economical solutions and results in small plants. The dryers are extremely robust and have no moving parts inside the process space. This results in minimal costs for maintenance and spare parts. Features • Low temperatures of the dried materials • Careful drying of sensitive...

Open the catalog to page 8

Reliable after-sales service Allgaier is a reliable partner from the start of a project to the after-sales service - with very competent consultant engineers, a high level of mobility and a dependable spare part service. Process knowledge for better processes Since the drying behaviour of moist products varies widely, the drying systems must be designed and adapted accordingly - a task which requires a lot of expertise, experience and instinct and is not easy. The Allgaier Test Center is attuned to this and finds the best solution with the aid of practical tests. With the support of...

Open the catalog to page 11

Competent spare parts and customer service Spare parts hotline: +49 7161 301-293 service-tro@allgaier.de • Spare and wearing parts in original quality • Modernization, retrofit, repair and service of existing drying systems • Process consulting • Energy consulting • Product development RIIGRIER PROCESS TECHNOLOGY ALLGAIER Process Technology GmbH Ulmer Strasse 75 73066 Uhingen Germany Phone: +49 7161 301-100 Fax: +49 7161 301-5035 process-technology@allgaier.de www.allgaier.de

Open the catalog to page 12All ALLGAIER PROCESS TECHNOLOGY catalogs and technical brochures

-

Vibration-Round-Screener VRS

3 Pages

-

Dry cleaning of stone

3 Pages

Archived catalogs

-

Contact Disc Dryer CDry

20 Pages

-

Pharmatical process

6 Pages

-

Rotary Drum

4 Pages

-

Allgaier Process Technology

16 Pages