Catalog excerpts

HYDRAULIC HOSE, FITTINGS & ADAPTERS

Open the catalog to page 1

CHART SYMBOLS Internal diameter Minimum bend radius Outside diameter Wall thickness Maximum working pressure Minimum burst pressure

Open the catalog to page 3

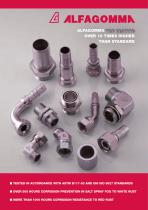

ALFAGOMMA TOP COATING OVER 10 TIMES HIGHER THAN STANDARD ■ TESTED IN ACCORDANCE WITH ASTM B117-03 AND UNI ISO 9927 STANDARDS ■ OVER 500 HOURS CORROSION PREVENTION IN SALT SPRAY FOG TO WHITE RUST ■ MORE THAN 1000 HOURS CORROSION RESISTANCE TO RED RUST

Open the catalog to page 4

NEW EXTRA FLEXIBLE BIO OIL RESISTANT HOSE RANGE n specially designed for bio oil full compatibility n extreme flexibility: up to 50% better bend radius compared to sae 100R n minetuff cover for top abrasion & ozone resistance n msha-approved fire resistant cover

Open the catalog to page 5

HALOGEN FREE RANGE NEW 2SC HF HALOGEN FREE HOSE ENVIRONMENTAL FRIENDLY Alfagomma has extended the HF range adding 2SC, available from June. The item code doesn’t change, but the new hose can be recognized by the logo HF in the branding text. The swaging parameters of 2SC-HF remain the same of the standard 2SC. ALSO AVAILABLE IN HF RANGE: www.alfagomma.com Dimensions shown may be changed without prior notice

Open the catalog to page 6

■ EXCELLENT ABRASION RESISTANCE (10 TIMES HIGHER THAN EN-ISO 6945 ■ HIGH OZONE RESISTANCE (10 TIMES MORE THAN THE STANDARD) ■ MSHA APPROVED COVER ■ ALTERNATIVE TO PROTECTIVE SLEEVE IN APPLICATIONS REQUIRING ABRASION RESISTANCE

Open the catalog to page 7

Appendix SETTING NEW STANDARD ALFAGOMMA cares for the environment and for your equipment among ALFAGOMMA’s newest products are ALFATECH 4000, 5000, 6000 spiral hose, low temperature, Temp Tech, MineTuff, SuperTuff hose and a complete coupling line (two pieces and precrimped ALFACRIMP systems). They join the extensive range of ALFAGOMMA hose, the high pressure hydraulic components that have set the standard for reliability and durability. DESIGN Throughout the world ALFAGOMMA has build up a name synonymous with quality, a reputation based on first class product, a commitment to research and...

Open the catalog to page 8

Appendix AND... 1. Always position a shield between you and any pressurised hydraulic lines when working next to them... or shut the pressure off. 2. Wear safety glasses. 3. Do not use your hands to check for leaks. Do not touch a pressurised hydraulic hose assembly with any part of your body, if fluid punctures the skin, even if no pain is felt, a serious emergency exists. Obtain medical assistance immediately. Failure to do so can result in loss of the injured body part or death. 4. Stay out of hazardous areas while testing hose assemblies under pressure. Use proper safety protection. 5....

Open the catalog to page 9

Type Approvals REFERENCE SPECIFICATIONS SAE - DNV - EN - DIN - CERCHAR - Society of Automotive Engineers Det Norske Veritas European Norm Deutsche Institute Normen Centre d’Etudes et Recherches Des Charbonnages de France U.S. Mine Safety and Health Administration Landesobergamt Nordrhein - Westfallen Australian Standard Bureau Veritas Germanischer Lloyd International organization for Standardization The listing below are intended only as guides in identifying which ALFAGOMMA hoses comply with requirements of various agencies. Hose Flexor 1TE/R6 HF Flexor 2TE HF Flexor 3TE/R3 HF Flexor 4...

Open the catalog to page 10

Hose Guidelines SAFETY GUIDE AND BASIC FACTORS FOR THE SELECTION, INSTALLATION AND MAINTENANCE OF HOSE AND HOSE ASSEMBLIES Hydraulic hose (and hose assemblies) has a limited life dependent on service conditions to which is applied. Subjecting hose (and hose assemblies) to conditions more severe than the recommended limits significantly reduce service life. Exposure to combinations of recommended limits (i.e., continuous use at maximum rated working pressure, maximum recommended operating temperature and minimum bend radius) will also reduce service life. Laminar flow - In laminar flow, the...

Open the catalog to page 11

User Guide TECHNICAL INFORMATION – NORMOGRAM OF THE FLOW The normogram herewith is pivotal to help you find the hose diameter by knowing the liquid flow and speed. In order to find the correct diameter you should trace a line between the flow value (l/min) and the suggested speed (m/sec) according to the kind of delivery (pressure or return). The value touched by the line in the central column will indicate the hose ID (mm/inches) that must be used. dash sizes Recommended maximum velocity for suction lines Recommended maximum velocity for return lines Recommended maximum velocity for...

Open the catalog to page 12

Hose Guidelines It is therefore important to calculate correctly the required flow line sizes. Undersized pressure lines results in high fluid velocity causing an excessive pressure drop, and heat built up, which impair overall system performance. Undersized suction lines can cause cavitation at the hydraulic pump inlet, affecting performance, shortening pump life, and creating excessive noise levels. The flow capacity normogram on page (12) is an aid to determine the correct hose internal diameter size, desired flow rate and recommended velocity. By the use of any two known factors, the...

Open the catalog to page 13

Hose Guidelines Do not use any ALFAGOMMA hose or fitting for any application requiring non-conductive hose, including but not limited to applications near high voltage electric lines, unless the application is expressly approved in the ALFAGOMMA technical publication for the product, the SAFETY GUIDE hose is both orange in colour and marked “non-conductive”, and the manufacturer of the equipment on which the hose is to be used specifically approves the particular ALFAGOMMA hose and fitting for such use. ALFAGOMMA does not supply any hose or fittings for conveying paint in airless paint...

Open the catalog to page 14

Hose Guidelines CORRECT ASSEMBLY INSTALLATION Satisfactory performance and appearance depend upon proper hose installation. Excessive length destroys the trim appearance of an installation and adds unnecessarily to the cost of the equipment. Hose assemblies of insufficient length to permit adequate flexing, expansion or contraction will cause poor power transmission and shorten the life of the hose. The diagrams below offer suggestions for proper hose installations to obtain the maximum in performance and economy. Adequate hose length is most important to distribute movement on flexing...

Open the catalog to page 15All ALFAGOMMA catalogs and technical brochures

-

LOW TEMPERATURE RANGE

6 Pages

-

Evolution

24 Pages

-

HIGH TEMPERATURE RANGE

6 Pages

-

INDUSTRIAL HOSE & FITTINGS

389 Pages

-

HYDRAULIC HOSE FITTINGS & ADAPTERS

450 Pages

-

OIL WELL CEMENTING

1 Pages

-

Hammer Union

4 Pages

-

Alfabbiotech

4 Pages

-

Hose in 61m

1 Pages

-

LIGHT SERIE CLAMPS - DIN 3015

14 Pages

-

QUICK RELEASE COUPLINGS

82 Pages

-

Industrial hose & fittings

256 Pages

-

OIL & GAS PRODUCT RANGE

128 Pages

Archived catalogs

-

hydraulic hoses

68 Pages

-

OIL & MARINE DIVISION

42 Pages