Website:

Albert Handtmann Armaturenfabrik GmbH & Co. KG

Website:

Albert Handtmann Armaturenfabrik GmbH & Co. KG

Group: Albert Handtmann Holding GmbH & Co. KG

Catalog excerpts

GERMAN ENGINEERING BY HANDTMANN handtmann Ideas for the future. ft |t*« all about the beer. KARBACH ^BREWING C?^tf ptouiUy. fotewtld in JCA'm

Open the catalog to page 1

Allagash Challenges Taking the Allagash Brewery from hose connections to a hard piped semi automated piping system. Automated and repeatable CIP process for cellar equipment. Allagash Brewing Company Allagash Brewing Company started in 1995 as a one-man operation in a small space on the outskirts of Portland, Maine. Founder Rob Tod had worked in a brewery setting before and recognized a void within the craft brewing movement. While both German and British styles had become prevalent throughout the U.S., the ever-creative Belgian styles were very difficult to find. Through his travels, Tod...

Open the catalog to page 2

Piping system for Fermentation/Aging and Hybrid CIP system including automation. Prefabricated customized pipe fence elements with stand pipe solution at the tank outlet already prepared for future growth. The automation of the system enables a clear control of the program sequences and the actual process parameters. The integrated data acquisition, data storage allows a representation of current process data, a well as a documentation of expired processes. Handtmann-Hybrid CIP skid guarantees best cleaning performance by intelligent mechanical engineering and software solutions. Stand pipe...

Open the catalog to page 3

Avery Challenges It's all about producing beer that we are proud of. “For us the quality of the product is driven by what happens in the cellar and the yeast propagation system.“ (Adam Avery) Due to the immense demand for Avery Beers, their previous 25.000-square-foot brewery has hit capacity in 2014. In the meantime, Adam Avery (Co-Founder and Owner) and his team moved to the new Green Field brewery in Boulder. Since 2015 another 2 successful expansions of the fermenting cellars were completed. During the latest expansion, fermenting cellar No. 3, 10 outdoor tanks are now sitting on a deck...

Open the catalog to page 4

Handtmann Solution “With their yeast propagation system Handtmann made a huge difference in our brewery, I might say they revolutionized the way we make beer.” (Adam Avery) Yeast Management • Tailor-made yeast propagation and yeast storage/pitching systems • Wort/yeast aeration devices • Best performance in terms of growing rates, hygienic execution and gentle treatment of yeast • Sophisticated and validated yeast processes handtmann New fermenting cellar No. 3 "inside" Yeast Management Versa Flex

Open the catalog to page 5

Bell's Challenges It started with a 15-gallon soup pot Fully automated new „Two Hearted" fermentation cellar with automated foam trap. "Replace hose connections" to generate hygienic, controllable and safe process structures. Founded by Larry Bell as a home brewing supply shop in 1983, Bell's Brewery, Inc. sold its first commercial beer in September 1985. Beer was initially brewed in a 15-gallon soup kettle and the company has grown remarkably from its production of 135 barrels (1 barrel = 31 gallons) in 1986 to over 310,000 barrels in 2014. Originally self-distributed, Larry and his staff...

Open the catalog to page 6

Handtmann Solution „SOL -piping system" for new fermentation cellar with foam trap. Latest Pipe fence expansion with individual tank pressure regulation and multifunctional tank utilization for 24 tanks. SOL (Short Outlet Loop) piping system The idea of the fully automated SOL piping systems is: • Keep the tank outlet pipe as short as possible to avoid yeast autolization • Keep the main product lines as short as possible to minimize product losses • Reduce the number of elbows for gentle product treatment • Guarantee easy maintenance and accessibility to valves and tank outlet for...

Open the catalog to page 7

Dogfish Head Challenges Fully automated yeast management system to propagate and store up to six yeast types simultaneously. Semi-automated fermentation and aging process with minimum work load. Dogfish Head Craft Brewery makes off-centered ales for off-centered people throughout the year. Many of their beers are available throughout the year, but some are only brewed once a year and in extremely limited supply – so be sure to grab them while you can. Log on to dogfish.com and click on the “Fish Finder” for a list of retailer accounts. High demand for CIO performance and execution with...

Open the catalog to page 8

Handtmann Versa Flex yeast management system supports the Dogfish philosophy of creativity and flexibility, easily achieving the required cell growth for all strains and gentle yeast treatment. Only 1 brewer per shift is needed to run the semi automated fermentation cellar. 4 Hybrid CIP skids guarantee great micro conditions from Brewhouse to bottling. ndtmann are truly partners cellaring in our and clean ing solutio place a gr ns. They eat effort to ensure the requir that all of ements D ogfish He provided ad set we in a truly re value eng tion. This ineered s process w oluorked gre from...

Open the catalog to page 9

Firestone Walker Challenge Firestone Walker Brewing Company FIRESTONE WALKER BREWING COMPANY High quality equipment standards are needed to create amazing, extraordinary beers". “Once beer production gets over 60 - 80.000 bbl, it starts getting complicated and the need for technology and process comes in." (Adam Firestone) brewed its first beer in 1996 in a small facility rented from the Firestone Vineyard estate in Santa Barbara County. In 2001 owners Adam Firestone and David Walker purchased the SLO Brewing Company located in Paso Robles, CA. Firestone Walker's ales are selectively...

Open the catalog to page 10

Semi-automated piping system for “tanks on skirts” with flexible usage as fermentation/storage and bright beer tanks. The Inova double seat valves with single seat lifting and balancer cleaning will ensure the fully automated process in the bright beer cellar. CIP - Hybrid system • Customized CIP programming and recipe development • Low water and chemical consumption are guaranteed by carefully engineered components and intelligent programming • Backwash features, dedicated tank cleaning procedures, hot cleaning of tanks dc Fully automated bright beer cellar Automated Hybrid CIP solutions...

Open the catalog to page 11All Albert Handtmann Armaturenfabrik GmbH & Co. KG catalogs and technical brochures

-

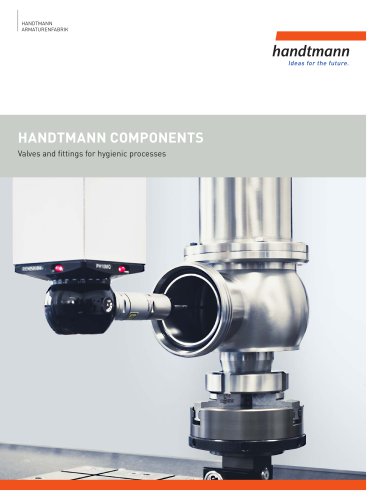

HANDTMANN COMPONENTS

24 Pages

-

Handtmann product catalogue

336 Pages

-

Handtmann Hop to the Top

2 Pages

-

RFC Radial Flow Column

4 Pages

-

CSS 2.0 Adsorber Material

2 Pages

-

CF Filter Technology

4 Pages

-

Handtmann Yeast management

12 Pages