Catalog excerpts

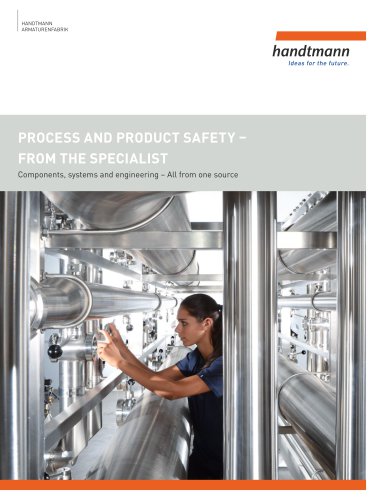

HANDTMANN ARMATURENFABRIK PROCESS AND PRODUCT SAFETY – FROM THE SPECIALIST Components, systems and engineering – All from one sourc

Open the catalog to page 1

PERFECT HANDTMANN ENGINEERING For your products and processes Albert Handtmann Armaturenfabrik GmbH & Co. KG Arthur-Handtmann-Straße 11 D-88400 Biberach/Riss

Open the catalog to page 2

From brewhouse to bottling - Handtmann Engineering provides solutions for the construction, renovation, expansion and optimization of your cold block. → Preparation and planning Our Engineering for your success → Tailor-made concepts to meet your aims and objectives → Tailor-made for your specific system → Handtmann expertise focuses on your process and plant parameters, resulting in excellent cost efficiency → Project management → Overall project planning in 3D → Our experienced team of engineers and brewing technologists support you with functional descriptions and flow diagrams from the...

Open the catalog to page 3

VERSA FLEX Yeast Management, the fully automated spa & wellness for your yeast cells YEAST MANAGEMENT Propagation, storage, revitalization

Open the catalog to page 4

YEAST WRANGLER semi-automated Tailor-made Yeast Management solutions with „Versa Flex“ and „Yeast Wrangler“. The global trend of brewing different specialty beers holds new challenges in the management of various yeast strains. The tailored Handtmann yeast management system, available as „Versa Flex“ and „Yeast Wrangler“, offer the best solution for the brewer. With multi-functional equipment and intelligent process design, different yeast strains can be simultaneously propagated, stored and revitalized. Through the use of proven Handtmann components and technology, crosscontaminations are...

Open the catalog to page 5

Handtmann double outlet seperates the beer and the yeast PIPING SYSTEMS For your fermentation, storage and bright beer tank area

Open the catalog to page 6

Fully automated fermentation / storage Tailor-made pipe fence combined with the piping system SOL with INOVA double seat valves Handtmann piping systems - Developed for your requirements. Handtmann develops, designs and manufactures piping systems, pipe fence elements and valve blocks for the brewing and beverage industries. Our systems from brewhouse to bottling are in worldwide use. The Handtmann piping systems are individually designed to the highest Piping System Properties ^ Completely prefabricated pipe fence elements and valve blocks ^ Highest quality due to prefabrication with...

Open the catalog to page 7

The Handtmann CIP media filtration through a ceramic Crossflow filter provides economical and ecological caustic recycling FILTRATION Fine and sterile filtration of beverages, gentle beer stabilization, innovative protein recovery

Open the catalog to page 8

MMS - Sterile filtration in front of the bottling line CSS - Continous beer stabilization From classic beer clarification to modern nanofiltration. MMS Multi Micro System fine and sterile filtration for beer The Multi Micro System is the filter that combines the classic features of the deep-bed filtration with modern technology. The MMS allows the preservation of product quality and combines a simple and safe procedure with the best biological safety. The delivery program includes plant sizes of 30 hl / h to 600 hl / h, fully automated on request. Your Benefits → Retains fresh taste and...

Open the catalog to page 9

CIP-SYSTEMS Hygienic & Hybrid systems

Open the catalog to page 10

Chemical dosing station of a CIP-system in a brewery Handtmann CIP-systems are designed and manufactured according to the latest technical developments under sanitary aspects. The systems are designed according to customer specific tasks and operating conditions. Matched to the process, cleaning programs guarantee maximum safety and productivity in daily use. CIP Hygienic & Hybrid Properties ^ For maximum hygiene requirements ^ Avoid „Cross Contamination" ^ Controlled storage of CIP media ^ Minimal consumption of cleaning media ^ Exact dosage control the cleaning media through flowmeters ^...

Open the catalog to page 11

Ethernet switch Ethernet switch Visualization fermentation Overview system structure A clear and functional system piping, with meaningful user-friendly automation, is the optimal condition for the efficient operation of a plant. The automation of the system enables a clear control of the program sequences and the actual process parameters. The integrated data acquisition, data storage allows a representation of current process data, as well as a documentation of expired processes. Our Competence Your Benefits → From small investment plan to the complex process plant we provide reliable,...

Open the catalog to page 13

Semi-automatic RFC System in batch production PROTEIN CAPTURE Protein purification / extraction

Open the catalog to page 14

RFC radial flow column for the industrial biotechnology Fully automatic RFC System in continuous production RFC Radial Flow Chromatography. Industrialist chromatography processes in biotechnology and in „Functional Food Applications“ such as lactoferrin recovery have been derived from the pharmaceutical industry. High investment costs for the plant were the result. The Handtmann RFC columns and the matched peripheral (piping, manifolds, CIP-systems) offer immense savings while maintaining fully automatic processes on an industrial scale. Your Benefits → RFC column content up to 265 liters →...

Open the catalog to page 15

handtmann Ideas for the future. YOUR PARTNER. aaaaa • aaaa aaaa aaaa aaaa aaaa aaaa Albert Handtmann Armaturenfabrik GmbH & Co. KG Arthur-Handtmann-Str. 11 88400 Biberach/Riss Germany Tel.: +49 7351 342-0 Fax: +49 7351 342-4255 sales.fittings@handtmann.de www.handtmann.de www.facebook.com/HandtmannArmaturenfabrik

Open the catalog to page 16All Albert Handtmann Armaturenfabrik GmbH & Co. KG catalogs and technical brochures

-

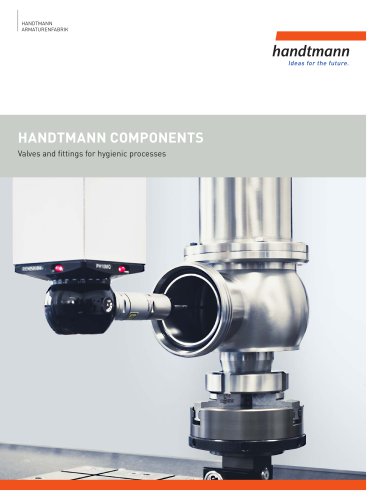

HANDTMANN COMPONENTS

24 Pages

-

Handtmann product catalogue

336 Pages

-

Handtmann Hop to the Top

2 Pages

-

RFC Radial Flow Column

4 Pages

-

CSS 2.0 Adsorber Material

2 Pages

-

CF Filter Technology

4 Pages

-

Handtmann Yeast management

12 Pages