Catalog excerpts

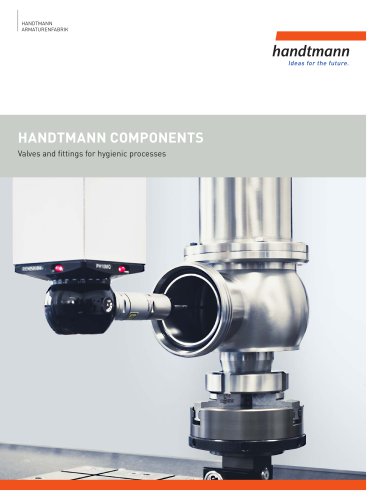

HANDTMANN ARMATURENFABRIK HANDTMANN COMPONENTS Valves and Fittings for Hygienic Processes - Technical Data

Open the catalog to page 1

OUR EXPERIENCE - YOUR SAFETY Products for your Industry Handtmann specialises in safe and reliable conveyance of liquid and gaseous media in the food industry. The business segments of Handtmann include components and valves, filtration and separation solutions, plant construction and comprehensive consulting services. Due to the high hygiene standards of the valves, they can be used by companies active in the fields of hygienic process engineering as well as in the beverage, dairy, chemical, bio and cosmetics industries. Brewing Industry Chemical Industry Beverage Industry Food Processing...

Open the catalog to page 2

01 SAFETY RELIEF VALVES 03 PRESSURE COMPENSATION VALVES 07 DOUBLE SEAT VALVES 11 SERVICE & SPARE PARTS Product film tank protection: Scan QR code with your smartphone or tablet -> watch the video of the Product film tank protection directly on the Handtmann website.

Open the catalog to page 3

Safety relief valve weight-loaded Type 32010 Finite elements calculation SAFETY RELIEF VALVES, SPRING - AND WEIGHT-LOADED Your first choice for hygienically sensitive areas Double guided valve rod, high quality pressure spring made of stainless steel YOUR BENEFIT: Vertical or horizontal installation and reproducible, safe function even in critical operating conditions Optimized valve disc construction for an easy on-site replacement of the seals. YOUR BENEFIT: Cost- and time saving All valve parts are exclusively made of stainless steel YOUR BENEFIT: Long-lasting, safe and low-maintenance...

Open the catalog to page 4

INOVA safety relief valve ASME (UV) execution Type 33551 Minimal dead space safety relief valve Type 33503 Nominal DN-sizes Nominal OD-sizes Set pressure (special pressure on request) Heating device Scale for pressure adjustment Media: Steams, gases, liquids Functional principle Options Manual lifting Pneumatic lifting Proximity switch Sealing against changing the pressure, changing the spring and by TÜV General execution: Materials: 1.4301, 1.4307, 1.4404 Sealing materials: EPDM, FKM, FFKM • Range of application EPDM: from -20 °C to +150 °C short-term • Range of application FFKM: from -20...

Open the catalog to page 5

Minisafe (overpressure protection) E.g. fermenter Type 33541 Cutting model bunging device Type 35103 OVERFLOW VALVES, PRESSURE COMPENSATION VALVES, BUNGING DEVICES Process safety by pressure relief and -constant Variable 360°- connectivity with double spherical housing YOUR BENEFIT: Flexibility and customer-specific piping design: short delivery periods One-piece double spherical housing; Thus, very tiny distance between the piping levels Counter-pressure optimized construction through valve piston with valve disk; Thus, no impact of the function by counter-pressure YOUR BENEFIT: Protection...

Open the catalog to page 6

INOVA overflow valve Type 33804 Cutting model combi valve Type 12605 vertical & horizontal vertical & horizontal Manual lifting Pneumatic lifting Proximity switch Type Nominal DN-sizes Opening pressure range Media: Steams, gases, liquids Installation Functional principle Options General execution: Materials: 1.4301, 1.4307, 1.4404 Sealing materials: EPDM, FKM, FFKM • Range of application EPDM: from -20 °C to +150 °C short-term • Range of application FKM/FFKM: from -20 °C to +160 °C Surface roughness of media touched parts: Ra ≤ 0,8 µm (other surface quality on request) Functional principle:...

Open the catalog to page 7

Vacuum valve spring-loaded Type 12515 Vacuum valve weight-loaded with lifting device Type 12504 VACUUM VALVES For the vacuum protection of vessels and systems Hygienic Design execution Separation of housing and flange; easy on-site replacement of the seals without complete disassembly of the valve, or any special tools YOUR BENEFIT: Easy to clean, prevention of microbiologically hazardous areas and contamination of any kind. YOUR BENEFIT: Cost and time saving Guided valve disk YOUR BENEFIT: Safe function even in critical operating conditions

Open the catalog to page 8

Cut model Vacuum valve Type 12525 Vacuum valve spring-loaded Type 12537 Nominal DN-sizes Opening pressure vertical & horizontal vertical & horizontal Functional principle Options Manual lifting Pneumatic lifting Proximity switch External CIP-device with splash guard Special opening pressure on request Plastic valve cone Stainless steel valve cone General execution: Materials: 1.4307, 1.4404 Sealing materials: EPDM • Range of application EPDM: from -20 °C to +150 °C short-term Surface roughness of media touched parts:

Open the catalog to page 9

Safety relief valve on a fermenter TANK TOP PLATE Modular, technical platform for a simple combination of different functions Modular assembly with various customized connection options YOUR BENEFIT: Flexibility and tailor-made solutions combined with short delivery times The entiry top plate is designed according to Hygienic Design Guidelines YOUR BENEFIT: Prevention of microbiologically hazardous areas and contamination of any kind One modular connection platform only, instead of multiple connections YOUR BENEFIT: Cost and time saving

Open the catalog to page 10

Safety relief valve spring-loaded with pneumatic lifting Diaphragm valve RLV-combination Vacuum valve weight-loaded with pneumatic lifting Measurement technology

Open the catalog to page 11

1-hole cleaining-air-valve combination (RLV) Type 09712 CLEANING-AIR-VALVE COMBINATION (RLV) Compact, modular, mechanical combination of various functions Modular assembly with various, customized connecting options YOUR BENEFIT: Flexibility and tailor-made solutions combined with short delivery times Execution in Hygienic Design YOUR BENEFIT: Easy to clean, prevention of microbiologically hazardous areas and contaminations of any kind

Open the catalog to page 12

2-hole cleaining-air-valve combination (RLV) Type 09902 2-hole cleaining-air-valve combination (RLV) on a yeast tank Vacuum valve Switch valve Spray ball Safety relief valve (during production) (during cleaning) Production • The tank is secured against overpressure and vacuum Cleaning • Tank CIP via spray ball, mounted at the first tank connection. • Approx. 90 % of the CIP liquid are being led through the spray ball for tank cleaning. • Approx. 10 % of the CIP liquid flows through switch valve, and cleans the seats of vacuum and pressure relief v

Open the catalog to page 13All Albert Handtmann Armaturenfabrik GmbH & Co. KG catalogs and technical brochures

-

Handtmann product catalogue

336 Pages

-

Handtmann Hop to the Top

2 Pages

-

RFC Radial Flow Column

4 Pages

-

CSS 2.0 Adsorber Material

2 Pages

-

CF Filter Technology

4 Pages

-

Handtmann Yeast management

12 Pages