Catalog excerpts

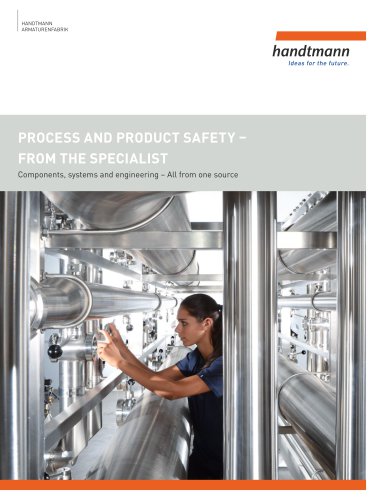

HANDTMANN ARMATURENFABRIK CONTROLLED STABILIZATION SYSTEM CSS The stabilizing system for the beverage industry

Open the catalog to page 1

The CSS is a gentle but highly effective beer stabilization The CSS is the cost effective stabilization alternative to regenerable PVPP method The CSS is a compact build, fully automated stabilizing plant The CSS stabilizing agent remains in the filter plant and can be regenerated and reused without losses for several years The CSS is easily incorporated into any existing filter line and aut

Open the catalog to page 2

The CSS consists of one or several modules which are completely filled with the adsorbent. The adsorbent is permanently retained between an inlet and an outlet screen, making the dosing of precoat and feed suspension prior to each stabilization unnecessary. Filtered, unstabilized beer flows through the CSS module containing the adsorbent. A contact time of a few seconds is enough to remove polyphenoles by adsorption. The adsorbent itself is based on a high-grade, crosslinked, insoluble agarose (polysaccharide) with a particle size between 100 – 300 μm. Polyphenoles are adsorbed and then...

Open the catalog to page 3

INNOVATION AT YOUR FINGER TIP Stabilization The CSS beer stabilization is fully automated, a touch of a button at filtration start is all it takes. Over the time of the stabilization run the flow rate adsorber/bypass is regulated automatically, so that the consistent stability is guaranteed throughout the stabilization run. Adjustments to accommodate changing conditions, beer types and stabilization requirements can be made easily, based on the data stored in the program. Regeneration The adsorbent can be regenerated several hundred times with caustic (NaOH). Sterilization is carried out...

Open the catalog to page 4

All of the described process steps do take place within the fully automated CSS plant: A defined amount of beer flows through the bypass → Unstabilized Both beer streams are then blended. The ratio adsorber to bypass gradually rises during the saturation of the adsorber → Uniformly stabilized beer is being produced → Easy adjustments to the ratio give the brewer the possibility to freely select the desired stability uniformly stabilized beer, adjusted to your desired beer stability and shelf life blending point A defined amount of beer flows through the adsorber → Intensive stabilization...

Open the catalog to page 5

STABILITY GUARANTEED The stability test as the most important test for beer stability, convinces unconditionally The CSS achieves excellent beer stability while treating the product gently. The treatment with the CSS generally removes fewer substances than PVPP. The adsorption of low molecular polyphenoles is lower. The organoleptic properties, the foam stability, beer color and bitterness units of the beer remain unchanged.

Open the catalog to page 6

Quality advantages → The degree of stabilization is adjustable → The CSS can be used over a long period of time with consistent results Environmental advantages → The amounts of water (waste water) and chemicals required for the regeneration and CIP are very low Technological advantages → The adsorbent is chemically/physically stabile, so that it can be regenerated without any losses → Due to the compact module, the CSS next phase volumes and pre and post runs are very small → The CSS has a small foot print and does not require much room height → Installation behind DE- or Crossflow Filter...

Open the catalog to page 7

YOUR PARTNER. Albert Handtmann Armaturenfabrik GmbH & Co. KG Arthur-Handtmann-Str. 11 88400 Biberach/Riss Germany Tel.: +49 7351 342-0 sales.fittings@handtmann.de www.handtmann.de www.facebook.com/HandtmannArmaturenfabrik bk 08.2017_AF500DE_CO The information and data on this pages do not constitute a warranty, and shall be subject to technical modifications. Errors and misprint are at reserve.

Open the catalog to page 8All Albert Handtmann Armaturenfabrik GmbH & Co. KG catalogs and technical brochures

-

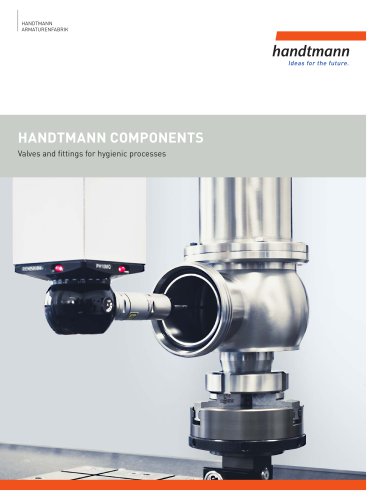

HANDTMANN COMPONENTS

24 Pages

-

Handtmann product catalogue

336 Pages

-

Handtmann Hop to the Top

2 Pages

-

RFC Radial Flow Column

4 Pages

-

CSS 2.0 Adsorber Material

2 Pages

-

CF Filter Technology

4 Pages

-

Handtmann Yeast management

12 Pages