Equipment & Process units AKW APPARATE + VERFAHREN GMBH Mineral processing, our expertise since

24Pages

Catalog excerpts

PROCESS UNITS Mineral processing,

Open the catalog to page 1

AKW Apparate + Verfahren GmbH Your specialist for mineral processing and environmental technology We offer solutions for the wet mechanical processing of minerals and ores as also for the separation of solids. AKW Apparate + Verfahren GmbH is a medium-sized, privately owned company focussed on process engineering and equipment as well as on plant engineering, construction and service. Since the foundation of AKW A+V GmbH in 1963 innovations, new product ideas and technologies have turned the company into a global operating enterprise with offices in Kiel, Moscow, Shanghai, São Paulo, Dubai,...

Open the catalog to page 2

Technical laboratory & trials Our state-of-the-art technical laboratory and the close collaboration between our research & development department and universities as well as other research institutes guarantee a high standard of technical development in process engineering. Besides our research and development performance we offer a wide range of test facilities. We assist you with our engineering activities during all planning steps: Analysis and test reports – Prebasic engineering – Basic engineering – Detail engineering – Plant execution until take-over. Equipment & process units The...

Open the catalog to page 3

Mineral processing, our expertise since 1963! More than 50 years of experience – tradition and know-how Besides technical competence in the successful planning, conception and implementation of projects in the wet-mechanical processing of mineral raw materials and ores, AKW A + V GmbH has expertise in the treatment of chemical and corrosive media for the chemical, pharmaceutical and food industries. – Processing of ores and minerals – Environmental technology – Glass, foundry and other industrial sands, kaolin and feldspar – Chemical, pharmaceutical and food industries – Contaminated soils...

Open the catalog to page 4

Equipment + Process Design AKA-TRIT High Performance Attrition Cells for purification of mineral raw materials and residues 6 AKA-VORTEX Hydrocyclones for solid-liquid separation 8 AKA-SPI DER Annular Distributors for a homogeneous and equal pressure distribution of the 8 AKA-VORTEX CBC CBC flat-bottom hydrocyclones 11 AKA-VORTEX PU LINER Hydrocylones with inlay 11 AKA-TRONIC Hydrocyclone Control Systems for stabilizing the cut size 12 AKA-STRAINER Antiblocking Filters to prevent plugging of small hydrocyclone nozzles 12 AKA-SPIN Spirals for separating particles of different densities 13...

Open the catalog to page 5

High Performance Attrition Cells A K A - TRIT The attrition process is used for cleaning raw and residual materials contaminated with adsorbed impurities or pollutants. In this process, the individual particles are stirred intensively in high-solid slurry, which causes any adherent pollutants or extremely fine particles to be rubbed off the particle surfaces. The patented high-performance attrition system of AKW Apparate + Verfahren GmbH enables a consistently effective attrition even under fluctuating inlet conditions Principle of operation In a high performance attrition the process...

Open the catalog to page 6

High Performance Attrition Cells A K A - TRIT Design features and advantages – Tank with vertical agitator and V-belt drive – 2-, 4- or 6-cell construction with chamber volume each cell 0.5 m³; 1.0 m³; 2.0 m³; or 3.0 m³ – Robust, wear-resistant and low-maintenance construction in steel/stainless steel with easily replaceable wear protection (rubber/PU) for tank and agitator – Computer-controlled, defined solids concentration – Connection to existing plant control system is possible – Retrofitting of existing attrition plants for high-performance attrition is possible Applications –...

Open the catalog to page 7

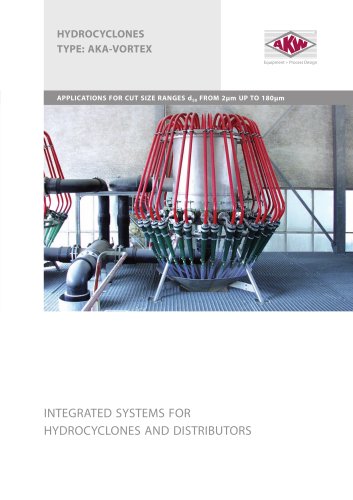

Hydrocyclones A K A - V ORT E X and Annular Distributors A K A - SPID E R Hydrocyclones are important and economically valuable components for wet-mechanical separation and classifying processes of minerals and mineral raw materials – matured construction, compact design and continuously developed and improved. Annular distributers in fully automatic mode allow a homogeneous and equal pressure distribution on every hydrocyclone in operation. AKA-VORTEX and AKA-SPIDER are applied across the industry in various areas: sorting, desliming, closed circuit grinding, solids recovery,...

Open the catalog to page 8

Hydrocyclones A K A - V ORT E X and Annular Distributors A K A - SPID E R TYPES AND SIZES OF HYDROCYCLONES NominalØ mm – Mineral raw materials and by-products (e.g. foundry sand, slag, Si-SiC-slurry, abrasives) Hydrocyclones are successfully in operation for classification of fine fractions of: – Minerals (e.g. Kaolin, Feldspar, Talcum, Chalk, Quartz, Gypsum, Bentonite, Zircon) – Ores (e.g. Iron ore, Bauxite, Zinc ore, Tin ore, Manganese ore, Chromite ore, Niobium-Tantalite-ore) – Chemical intermediates APPLICATIONS FOR CUT SIZE RANGES d50 FROM 2 μm UP TO 180 μm Types of AKA-VORTEX –...

Open the catalog to page 9

Modularity of the components The modular arrangement on the building block principle makes the series AKA-VORTEX flexible and adaptable to different operating conditions. Due to the possibility to combine different components of the AKA-VORTEX in different versions, several modifications with respective flow rates and results can be created from a series. Example AKA-VORTEX RWH8124: Drawing Capacity / Throughput curves for hydrocyclone 350 Test-Medium: Water Temperature: 20°C Data for Poyurethane 300 Special versions of the AKA VORTEX With our modern equipped laboratory and a close...

Open the catalog to page 10

Flat-bottom hydrocyclones AKA-VORTEX CBC Assembly flow, resulting from high centrifugal forces in the upper part and low centrifugal forces in the lower part of the hydrocyclone, transport pressure-compensated particles on the flat ground to the middle and allow the discharge with little risk of blockage. The hydrocyclone is maintenance-friendly equipped with a removable, highly wear-resistant PU liner. For the PU liner different qualities according to the requirements can be selected and allow accordingly applications under a variety of conditions and temperature environments. Hydrocyclone...

Open the catalog to page 11All AKW Apparate + Verfahren GmbH catalogs and technical brochures

-

Special Applications

8 Pages

-

SPARE PARTS & SERVICE

8 Pages

-

ENGINEERING

8 Pages

-

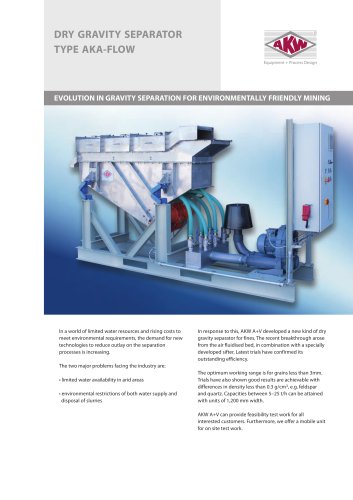

DRY GRAVITY SEPARATOR

2 Pages

-

Hydrocyclones

4 Pages