Catalog excerpts

1 Guided B oring M achine (GBM) Technic a l M anual

Open the catalog to page 1

2 Method Of Operation - 240A/308A/339A/4812A Guided Boring Machine (GBM) equipment is used with pipe outside diameters from 4 to 48 inches. The Guided Boring Method is a trenchless installation method for small diameter pipes with the grade and alignment precision the gravity sewer and water industry demand. The pipe installation involves a threestep process starting with launch and reception shafts strategically located to minimize surface disruption. For gravity sewer installation, where line and grade accuracy are paramount, the Akkerman Guided Boring Machine provides the precision...

Open the catalog to page 2

3 STEP 1: PRECISE INSTALLATION OF PILOT TUBES The first step in the Guided Boring Method is the installation of the pilot tubes on line and grade. The pilot tubes are inserted through the ground from the launch shaft to the reception shaft. On the leading end of the pilot tube is the steering head with an angled tip. Theodolite/Camera, Sighted Down Center of Pilot Tubes In the steering head is a battery powered LED illuminated target that is visible to the operator by means of a theodolite, camera, and monitor. The theodolite is set on line and grade and is positioned to view the target...

Open the catalog to page 3

5 GBM_LatchingFrame339A High pressure valves for jacking, rotation, frame travel, and PCH/PRH control functions. The quick couplers connect to the pressure, return, load sense and case drain hydraulic hoses from the GBM P100Q or P150Q Power Pack. Drive Swivel Adapter With Fluid Connector And Alignment Adapter Dual travel motors for ease of advancing gear box along the frame rails. Operator platform located 18” above shaft floor provides firm footing to keep the operators above the water and mud. Hydraulic pressure gauges for monitoring thrust and rotation system pressures. Low pressure...

Open the catalog to page 5

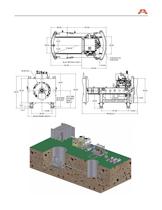

6 Jacking Frame Dimensions - 308A Minimum Shaft Requirements & System Layout Installing Pilot Tubes Dimensions are shown in inches

Open the catalog to page 6

7 Installing Auger Casings Jacking Frame Dimensions - 339A Minimum Shaft Requirements & System Layout Dimensions are shown in inches

Open the catalog to page 7

9 GBM_LFRoundSquareShaftAdptr RevB Common pins secure the round or square shaft adapters to the frame end assemblies. The hydraulic make-up tool is used to tighten each section of pilot tubes as they are installed in the launch shaft. In pull back operation, the make-up tool is used to Three roller bracket assemblies support the separate the pilot tubes in the launch shaft. line and weight of the temporary casing and product pipe in the launch shaft. The frame end assemblies are removable for ease of installing frame extentions.

Open the catalog to page 9

11 GBM_SingleStageFrame, FA40027F Hydraulic pressure gauges for monitoring thrust and rotation system pressures. The quick couplers connect to the pressure, return, load sense, and case drain hydraulic hoses from the GBM P100Q Power Pack. Dual 48” Single Stroke Cylinders Drive Swivel Adapter With Fluid Connector And Alignment Adapter High pressure valves for jacking, rotation, & frame travel functions. Low pressure valves for hydraulc make-up tool, rotation speed, and auxiliary functions. The hydraulic make-up tool is used to tighten each section of the pilot tubes as they are installed in...

Open the catalog to page 11

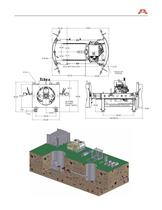

12 Jacking Frame Dimensions - 240A Minimum Shaft Requirements Dimensions are shown in inches

Open the catalog to page 12

13 System Layout - 240A Installing Pilot Tubes

Open the catalog to page 13

15 FEATURES • Assembly includes auger boring adapter and mounting hardware for the GBM 240A Single Stage Frame. • Increases both the accuracy and profitability of your auger boring machine by using the GBM 240A frame with your auger boring machine. • Adapter designed for ease of installation or removal from auger rig track. No special tools or welding required. Adapter is bolted in place to GBM 240A jacking frame. • Once pilot tubes are installed, complete bore as a standard auger boring operation. • Custom adapters are available upon request. • Increase Productivity Of Your Auger Boring...

Open the catalog to page 15

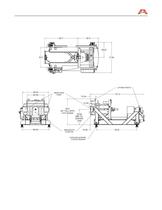

17 GBM_P100QPowerPack, F42440F Hose Reels For Ease Of Hose Management Suction Line Hydraulic Shutoffs For The Feed Pump, And Cooling Pump 50 gal (189 L) Hydraulic Reservoir The hydraulic reservoir includes an oil level and temperature gauges. Filtered Hydraulic Return Oil With Indicator Pilot tube breakout tool is used in the reception shaft to loosen the pilot tube joints. Four Cylinder, 99 HP Tier III Diesel Engine Walk-Through Tooling Storage Area The remote pendant contains the engine tachometer, hourmeter, engine oil pressure gauge, water temperature gauge, electronic engine speed...

Open the catalog to page 17

19 GBM_P150QPowerPack, F40035F Hose Reels For Ease Of Hose Management And Walk-Through Tooling Storage Area Suction Line Hydraulic Shutoffs For The Feed Pumps And Cooling Pump The remote pendant contains the engine tachometer, hourmeter, engine oil pressure gauge, water temperature gauge, electronic engine speed control, and ignition switch. 50 gal (189 L) Hydraulic Reservoir The hydraulic reservoir includes an oil level and temperature gauges. Filtered Hydraulic Return Oil With Indicator Pilot tube breakout tool is used in the reception shaft to loosen the pilot tube joints. Four Cylinder,...

Open the catalog to page 19

21 GBM_4812A, FA40034F The quick couplers connect to the pressure, return, load sense, case drain hydraulic hoses from the GBM Power Pack, along with the PCH hydraulic hoses. Drive Swivel Adapter With Fluid Connector And Alignment Adapter Low pressure valves for hydraulic make-up tool, push plate brake and staging functions. High pressure valves for jacking and rotation functions. Hydraulic pressure gauges for monitoring thrust, rotation and cutter bit system pressures. Four cylinders provide up to 200 ton thrust capacity. Operator control center for ease of operating and monitoring of...

Open the catalog to page 21

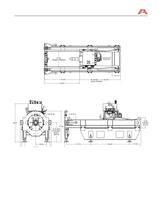

22 Jacking Frame Dimensions - 4812A Minimum Shaft Requirements Dimensions are shown in inches

Open the catalog to page 22

23 System Layout - 4812A Installing Pilot Tubes Installing Auger Casings Installing Powered Cutter Head

Open the catalog to page 23All Akkerman catalogs and technical brochures

-

GBM 48 Series Jacking Frame

4 Pages

-

P100 Power Pack

2 Pages

-

P150 Power Pack

2 Pages

-

P250D Power Pack

2 Pages

-

P275 Power Pack

2 Pages

-

GBM Guidance System

2 Pages

-

Notched Thrust Casings

2 Pages

-

TBM Series II

2 Pages

-

5000 Series Pump Unit

2 Pages

-

EH2550 Bentonite Pump

2 Pages

-

5000 Series II Pump Unit

2 Pages

-

P400/P600 Power Pack

2 Pages

-

EH2250 Bentonite Pump

2 Pages

-

Akkerman Product Guide

15 Pages

-

1548 Haul Unit

2 Pages

-

524 Haul Unit

2 Pages

-

TBM

2 Pages

-

Control Container

2 Pages

-

Eliminator

2 Pages

-

PCH 36-44"

2 Pages

-

PCH 20-28.5"

2 Pages

-

PRH Kit

2 Pages

-

Jetting and Lubrication Pump

2 Pages

-

P275T Power Pack

2 Pages

-

P150Q Power Pack

2 Pages

-

P100Q Power Pack

2 Pages

-

4812A Jacking Frame

2 Pages

-

308A/339A Jacking Frame

2 Pages

-

240A Jacking Frame

2 Pages

-

EPBM Systems Product Guide

1 Pages

-

Akkerman Product Guide

15 Pages

-

5000 Series Jacking System

1 Pages

-

Tunnel Boring Machine (TBM)

1 Pages

-

Microtunneling

1 Pages