Catalog excerpts

CORPORATE OVERVIEW Since 1973, Akkerman develops, manufactures markets and supports quality equipment that accurately installs a variety of underground infrastructure. We are proud to be the only North American manufacturer for our variety of equipment and a recognized worldwide competitor. Our vision statement, Goal Driven for Customer Success, is integrated into all levels within the Akkerman has grown with the demands necessitated by our industry. Over the years, we have introduced manned pipe jacking, microtunneling, guided boring and earth pressure balance systems to increase the range...

Open the catalog to page 2

GUIDED BORING - 308A/339A SYSTEM Akkerman's Guided Boring Machine (GBM) method, often referred to as pilot tube microtunneling, offers customers extended and accurate drive lengths in various ground conditions. The GBM provides the spoil removal process of the auger boring machine and the same level of accuracy as traditional microtunneling—all in one compact, multifaceted The 308A/339A Jacking Frames allows operators to install pipe from an 8 or 9-foot (2.4/2.7 m) shaft. Our distinctive dual-walled pilot tube allows liquid lubrication throughout installation, thus minimizing jacking force...

Open the catalog to page 3

Operators of the 240A Jacking Frame have independent control of pipe jacking and rotation for smooth and continuous advancement. The universal auger bore rig adapter and mounting hardware for the 240A Jacking Frame fits 30-72 inch (762-1,829 mm) track. Weld-on reaming heads are available from 12-72 inch (305-1,829 mm) OD to match steel casing pipe diameter. GUIDED BORING - 240A SYSTEM One of the most common applications for the single stage 240A Jacking Frame is its use in conjunction with a standard auger boring rig. With the GBM providing guidance, contractors are empowered with the...

Open the catalog to page 4

The 4812A Jacking Frame is capable of installing length. It features independent jacking, rotation The P275T Power Pack features a six-cylinder, liquid cooled, 275 HP (205 kW) diesel engine with three variable piston pumps for independent operation of the jacking, rotation and PCH. The P150Q Power Pack features a four-cylinder, liquid cooled, 154 HP (115 kW) engine with three variable-piston pumps for independent operation GUIDED BORING - 4812A SYSTEM The 4812A Jacking Frame was developed as a direct result of the design and capability demands desired by our customers. The 4812A Jacking...

Open the catalog to page 5

MICROTUNNEL BORING MACHINES Akkerman's Microtunnel Boring Machines (MTBM) install pipe in ground conditions that are generally below the water table. Microtunneling is referred to as non-manned, remote- controlled, continuously supported pipe jacking. Applications most suitable for this method are gravity flow pipelines requiring precise line and grade in poor soil conditions. As the only U.S. manufacturer of microtunneling equipment, our systems are a fusion of high productivity, dependability and accuracy in a wide range of soil conditions, without the need The electrically powered,...

Open the catalog to page 6

MICROTUNNEUNG JACKING FRAMES Our family of keyhole jacking frames allow the customer to operate a high-capacity jacking frame out of a minimal launch Collectively, keyhole jacking frames will operate out of a 16- 24 foot (4.87 - 7.3 m) shaft and feature 800-1,200 tons*** (726-1,089 mt) of thrust capacity at 8,000 psi (550 bar) while advancing pipe at a rate of 15-9.5-inch (381-241 mm) per minute. All standard frames are able to push 10-foot (3 m) length pipe sections and extensions are available for longer pipe. The keyhole frame utilizes keyed blocks on the jacking cylinders to...

Open the catalog to page 7

A typical 5000 Series II system in a shaft is shown here on a project site. The interior of the TBM allows the operator full control over the forward movement and spoil removal processes while maintaining the cutter face excavation. The operator's station is located along the inside of the TBM wall beside the conveyor. From this position, the operator can control the TBM steering and monitor or adjust as necessary. Akkerman's manned Tunnel Boring Machines (TBMs) are the epitome of pipe jacking power, control and accuracy in an array of soil conditions.TBMs are suitable where manned entry is...

Open the catalog to page 8

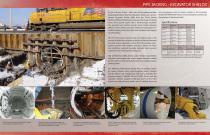

PIPE JACKING - EXCAVATOR SHIELDS For 96- 168 inch (2,438 - 4,267 mm) OD tunneling and pipe jacking applications, Akkerman Excavator Shields are a proven partner. Excavator Shields differ from the Tunnel Boring Machine (TBM) in that they do not have a cutter head or rotating drum, and excavate spoils with a backhoe-type excavator. The excavator and control console easily transfer between different sized shields. Excavator Shields are appropriate for traditional pipe jacking, liner plate and ring-beam and lagging tunnel building. The EX 50 Excavator, housed inside the shield, assists in the...

Open the catalog to page 9

PIPE JACKING - 5000 SERIES II PUMP UNIT The 5000 Series II Pump Unit is part of a complete, all-in-one pipe jacking system fortheTunnel Boring Machine (TBM) and contains a hydraulic power unit,skid base sections and a thrust yoke.This versatile system easily adapts to any jacking pipe in any length with an appropriately sized TBM and yoke. The 5000 Series II Pump Unit features two independent hydraulic systems for jacking and TBM supply functions. The high-pressure, 50 HP (37 kW) electric motor powers the two main jacking cylinders and auxiliary jacking functions. The two low-pressure 100...

Open the catalog to page 10

The EH2250 Bentonite Pump provides lubricant to the outside of the pipe, reducing friction between the pipe and ground, thus decreasing the thrust. Our dual 250-gallon (946 L) tanks continuously mix and pump bentonite solution. The 1548 Haul Unit system, intended for the TBM 600- BS 1440 models, consists of a haul unit, dirt bucket and track. It features a 15 HP (11.2 kW) electric drive, low-end torque, extended range of speed, regenerative motor braking and many safety features. The 524 Haul Unit system can be used with our TBM 420-540 models.The 524 is equipped with a hydraulic hand...

Open the catalog to page 11

Many cutter head configurations are available for The pipe jacking EPBM control console is located Spoils are mixed with foam and slurry to ease in optimum soil displacement from the EPBM face. inside the tunnel where operators have full excavation. control over all functions.The screw conveyor advances spoils into the haul unit dirt bucket. EARTH PRESSURE BALANCE SYSTEMS The Akkerman name has long been associated with industry leading projects. Earth Pressure Balance Machine (EPBM) systems have furthered our project realm while offering customers a U.S. manufactured product with the same...

Open the catalog to page 12All Akkerman catalogs and technical brochures

-

GBM 48 Series Jacking Frame

4 Pages

-

P100 Power Pack

2 Pages

-

P150 Power Pack

2 Pages

-

P250D Power Pack

2 Pages

-

P275 Power Pack

2 Pages

-

GBM Guidance System

2 Pages

-

Notched Thrust Casings

2 Pages

-

TBM Series II

2 Pages

-

5000 Series Pump Unit

2 Pages

-

EH2550 Bentonite Pump

2 Pages

-

5000 Series II Pump Unit

2 Pages

-

P400/P600 Power Pack

2 Pages

-

EH2250 Bentonite Pump

2 Pages

-

1548 Haul Unit

2 Pages

-

524 Haul Unit

2 Pages

-

TBM

2 Pages

-

Control Container

2 Pages

-

Eliminator

2 Pages

-

PCH 36-44"

2 Pages

-

PCH 20-28.5"

2 Pages

-

PRH Kit

2 Pages

-

Jetting and Lubrication Pump

2 Pages

-

P275T Power Pack

2 Pages

-

P150Q Power Pack

2 Pages

-

P100Q Power Pack

2 Pages

-

4812A Jacking Frame

2 Pages

-

308A/339A Jacking Frame

2 Pages

-

240A Jacking Frame

2 Pages

-

EPBM Systems Product Guide

1 Pages

-

Akkerman Product Guide

15 Pages

-

5000 Series Jacking System

1 Pages

-

Tunnel Boring Machine (TBM)

1 Pages

-

Microtunneling

1 Pages

-

Guided Boring Machines (GBM)

52 Pages