Catalog excerpts

Equipment Systems

Open the catalog to page 1

Overview of AKKERMAN Akkerman, a recognized worldwide competitor, manufacturers a full range of pipe jacking and tunneling equipment Akkerman offers sales and service domestically and internationally Akkerman was founded in 1973 by D.H. Akkerman Construction Company Akkerman is privately held, family-owned and operated Akkerman equipment is engineered and manufactured at its corporate headquarters in Minnesota in a 65,000 sq. ft. state-of-the-art facility

Open the catalog to page 2

Vision statement: Goal driven for customer success. Mission statement: We develop, manufacture, market and support quality equipment that accurately installs a variety of underground Core values: We provide high quality engineered products to our customers at competitive We provide a safe and secure workplace We solicit input from our employees, We are committed to meet and exceed customer expectations and we do so with integrity, diligence and without

Open the catalog to page 3

Guided Boring Machine (GBM) Systems

Open the catalog to page 4

Guided Boring Systems Akkerman began manufacturing Guided Boring Machine (GBM) systems in 2001 Using pilot tubes, our method installs 4-48” (102 – 1,219 mm) OD pipe with grade and alignment precision A GBM system combines the spoil removal process of the auger boring machine with the accuracy of a microtunneling system in various ground conditions for gravity flow installations Equipment systems feature lots of versatility with many accessory options to maximize the customer’s investment Systems can be quickly set-up and moved for the next drive Installs: reinforced concrete, steel casing,...

Open the catalog to page 5

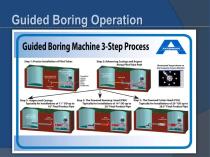

1 Guided Boring Machine 3-Step Process Step 2: Advancing Casings and Augers Along Pilot Tube Path lllummjtrd Target ihown on the Computer S<ra*n Monitor

Open the catalog to page 7

Guided Boring Systems

Open the catalog to page 8

Akkerman GBM Jacking Frames offer unmatched versatility and advanced engineering GBM Model Max. PipeOD Min. Shaft Frame Type

Open the catalog to page 9

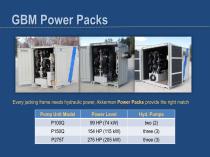

Every jacking frame needs hydraulic power, Akkerman Power Packs provide the right match Pump Unit Model Power Level Hyd. Pumps

Open the catalog to page 10

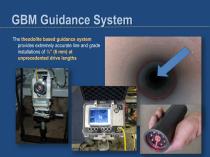

GBM Guidance System The theodolite based guidance system provides extremely accurate line and grade installations of ¼” (6 mm) at unprecedented drive lengths

Open the catalog to page 11

GBM Pilot Tubes Akkerman’s unique dual-walled pilot tubes allow liquid lubrication to be distributed throughout installation, thus minimizing jacking forces and rotational torque for expedited pilot tube installation

Open the catalog to page 12

GBM Eliminator The eliminator cutter head is used in nondisplaceable soils, in a two-step method, eliminating the pilot tube step The 16” (406 mm) OD cutter head features conical bullet bits and jetting nozzles to increase cutting performance Hollow augers and casing are paired with this unit for the guidance system’s line of sight to the target The eliminator works with all sizes of GBM jacking frames

Open the catalog to page 13

The Powered Cutter Head (PCH) is an upsizing tool for a variety of ground conditions Frame Type

Open the catalog to page 14

The Powered Reaming Head (PRH) kit is a hydraulically-driven, upsizing tool that can install 14-20” (350-500 mm) OD final product pipe The PRH allows customers to bore multiple pipe diameters with 11” (279 mm) casings and augers

Open the catalog to page 15

GBM Accessories – Cutter Head The cutter head with integral swivel is an upsizing tool used between the pilot tube adapter and lead casing for hard ground conditions The bearing swivel allows the pilot tubes to remain stationary while the cutting teeth rotate through the ground

Open the catalog to page 16

GBM Accessories – Auger Boring Guiding an auger boring rig with a GBM jacking frame and pilot tubes results in: improved accuracy longer drive potential smaller casing diameters faster installations ability to find hidden obstacles

Open the catalog to page 17

GBM Accessories – Auger Boring Weld-on reaming heads are available from 12-72” (305-1,829 mm) OD to match steel casing pipe diameter A pilot guide rod swivel is used in place of a weld-on reaming head to reduce thrust at the face of the bore The universal auger bore rig adapter fits 30-72” (762-1,829 mm) auger bore rig track

Open the catalog to page 18

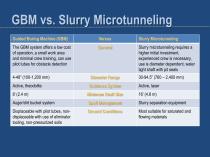

GBM vs. Slurry Microtunneling Guided Boring Machine (GBM) Slurry Microtunneling The GBM system offers a low cost of operation, a small work area and minimal crew training, can use pilot tubes for obstacle detection Slurry microtunneling requires a higher initial investment, experienced crew is necessary, use is diameter dependent, water tight shaft with pit seals Diameter Range Guidance System Active, laser Minimum Shaft Size Auger/dirt bucket system Spoil Management Slurry separation equipment Displaceable with pilot tubes, nondisplaceable with use of eliminator tooling, non-pressurized...

Open the catalog to page 22

Tunnel Boring Machine (TBMs) & Excavator Shield Systems

Open the catalog to page 23

TBMs & Excavators Akkerman began manufacturing tunnel boring and excavator shield systems in 1973 Diameters from 48-168” OD (1.2-4.3 m) Ideal in ground conditions where personnel entry is permitted Both systems are passive laser guided and manually controlled for accuracy TBMs have a rotating drum and feature interchangeable cutter heads for various soil conditions Excavator shields extract spoil with a digging type machine Both systems use conveyors and haul units for spoil removal Installs: reinforced concrete, steel casing, fiberglass, centrifugally cast fiberglass reinforced polymer...

Open the catalog to page 24

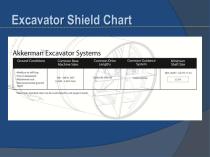

Excavator Shield Chart

Open the catalog to page 26

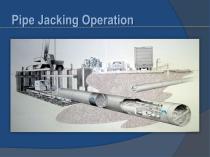

Pipe Jacking Operation

Open the catalog to page 27

Pipe Jacking Options

Open the catalog to page 28

TBM TBMs direct install pipe from 48-114” (1,219 – 2,896 mm) OD The system is laser guided with a selfleveling, passive laser and steering joints to ensure line and grade accuracy for gravity flow installations TBMs have interchangeable cutter heads for various soil conditions with a rotating drum An optional closed face cutter face is available for unstable ground conditions An optional mixed face cutter face is available for non-displaceable spoils for the Series II TBMs

Open the catalog to page 29

Excavator Shields Excavator Shields install pipes from 100-168” OD (2,540 – 4,267 mm) Spoils are excavated with a backhoe type excavator Differs from the TBM in that they do not have a cutter head or rotating drum Used for traditional pipe jacking, liner plate and ring-beam and lagging installations Hydraulically powered and features a passive laser guidance system The operator controls the excavator’s movement with a joystick and foot controls while mindful of the grade

Open the catalog to page 30All Akkerman catalogs and technical brochures

-

GBM 48 Series Jacking Frame

4 Pages

-

P100 Power Pack

2 Pages

-

P150 Power Pack

2 Pages

-

P250D Power Pack

2 Pages

-

P275 Power Pack

2 Pages

-

GBM Guidance System

2 Pages

-

Notched Thrust Casings

2 Pages

-

TBM Series II

2 Pages

-

5000 Series Pump Unit

2 Pages

-

EH2550 Bentonite Pump

2 Pages

-

5000 Series II Pump Unit

2 Pages

-

P400/P600 Power Pack

2 Pages

-

EH2250 Bentonite Pump

2 Pages

-

Akkerman Product Guide

15 Pages

-

1548 Haul Unit

2 Pages

-

524 Haul Unit

2 Pages

-

TBM

2 Pages

-

Control Container

2 Pages

-

Eliminator

2 Pages

-

PCH 36-44"

2 Pages

-

PCH 20-28.5"

2 Pages

-

PRH Kit

2 Pages

-

Jetting and Lubrication Pump

2 Pages

-

P275T Power Pack

2 Pages

-

P150Q Power Pack

2 Pages

-

P100Q Power Pack

2 Pages

-

4812A Jacking Frame

2 Pages

-

308A/339A Jacking Frame

2 Pages

-

240A Jacking Frame

2 Pages

-

EPBM Systems Product Guide

1 Pages

-

Akkerman Product Guide

15 Pages

-

5000 Series Jacking System

1 Pages

-

Tunnel Boring Machine (TBM)

1 Pages

-

Microtunneling

1 Pages

-

Guided Boring Machines (GBM)

52 Pages