Catalog excerpts

Advances in Pipe Jacking and Tunneling with Akk T li ith Akkerman S i II Series Equipment q p Presented by: y Chris Sivesind Sales Engineer Akkerman, Inc. csivesind@akkerman.com i i d@ kk Part II of III November 28, 2012

Open the catalog to page 1

® 5000 Series II Pump Unit System ® Tunnel Boring Machines - Series II ® Increased capabilities and the enhancements for each ® Support equipment: Haul Units, Yokes and IJS's

Open the catalog to page 2

AKKERMAN Founded in 1973 Privately held, family-owned and operated Global sales and service Engineered and manufactured in USA Full range of innovative pipe jacking and tunneling equipment

Open the catalog to page 3

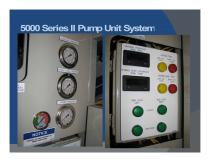

5000 Series Pump Unit System

Open the catalog to page 5

5000 Series II Pump Unit System: Design G Goals Better specifications equating to increased efficiency Improve ergonomics Compatibility I Improve safety for operators f t f t Integrated dual -feed pump Same dimensions Improved component availability Improve aesthetics

Open the catalog to page 6

5000 Series II Pump Unit System: Enhancements Simplified Design p g Two independent hydraulic systems Integrated dual-feed capabilities while keeping same height dimension as the single-feed 5000 Overall dimensions changed by 10” of added depth

Open the catalog to page 7

5000 Series II Pump Unit System: Enhancements Extended vertical clearance for laser Improved operator’s station- eye level gauges and indicator lights-hand level hydraulic co t o s d cato g ts a d e e yd au c controls Lower noise levels, electric motor for cooling circuit eliminated Phase connection error indicator light Two reservoirs one for high and one for low pressure

Open the catalog to page 8

5000 Series II Pump Unit System: Enhancements Overall improved hydraulic plumbing resulting in fewer leaks Easier to service New operators can be trained quickly Series II unit is compatible with all existing Akkerman TBM’s, Haul Systems and jacking yokes

Open the catalog to page 9

5000 Series II Pump Unit System 400 Tons of Jacking Force Diameter Range 36”-144” 120 GPM @ 3000 PSI Hydraulic Dual Feed, standard on y Series II TBM Original 5000 required an auxiliary pump to achieve dual g q yp p feed-increased height clearance IJS hydraulic p y pressures were reduced from 8400 PSI to 5800 PSI which will require the use of more IJS cylinders.

Open the catalog to page 10

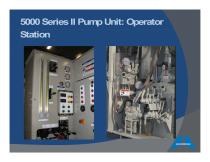

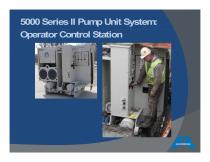

5000 Series II Pump Unit: Operator Station Station

Open the catalog to page 11

5000 Series II Pump Unit System

Open the catalog to page 12

5000 Series II Pump Unit System: Operator C O Control Station S

Open the catalog to page 13

5000 Series II Pump Unit System

Open the catalog to page 14

Tunnel Boring Machine- Series II g

Open the catalog to page 16

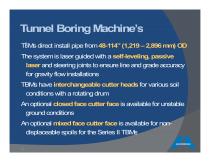

Tunnel Boring Machine’s Machine s TBMs direct install pipe from 48-114” (1,219 – 2,896 mm) OD The system is laser guided with a self-leveling, passive laser and steering joints to ensure line and grade accuracy for gravity flow installations TBMs have interchangeable cutter heads for various soil conditions with a rotating drum diti ith t ti d An optional closed face cutter face is available for unstable ground conditions An optional mixed face cutter face is available for nondisplaceable spoils for the Series II TBMs 17

Open the catalog to page 17

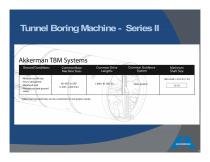

AkkermanTBM Systems Ground Conditions • Medium to stiff clay ■Weatherd rock • Non-pressurized ground Common Base Machine Sizes Common Drive Common Guidance Laser, passive Shaft Size *Akkerman standard sizes can be customized to suit project needs.

Open the catalog to page 18

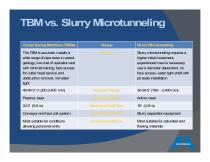

TBM vs. Slurry Microtunneling Tunnel Boring Machines (TBMs) Slurry Microtunneling The TBM is accurate, installs a wide range of pipe sizes in varied geology, low cost of operation and with minimal training, face access for cutter head service and obstruction removal, not water tight Slurry microtunneling requires a higher initial investment, experienced crew is necessary, use is diameter dependent, no face access, water tight shaft with pit seals installation Diameter Range Passive, laser Guidance System Active, laser Minimum Shaft Size Conveyor and haul unit system C Slurry separation...

Open the catalog to page 19

Tunnel Boring Machine - Series II: Design Goals G Better drive reliability Increased torque Capable of excavating mixed ground conditions as well as soft ground and soft/weathered rock Bi-Directional Rotation, variable speed cutter head rotation Improved operator ergonomics Simplify the hydraulics and minimize leak points Improve aesthetics Easier to build

Open the catalog to page 20

Tunnel Boring Machine - Series II: Enhancements Fully sealed and lubricated tri-roller bearing-equating to better drive reliability Motors capable of 5,000 psi high-pressure, producing higher torque q Series II TBMs offer 40% more torque than first series TBM’s Simplified Hydraulic System

Open the catalog to page 21

Tunnel Boring Machine–Series II: Enhancements Operator Safety: machine e-stop Improved ergonomics- controls are centrally located and p g y easier to operate Robust construction for the expanded range of g p g geology gy the machine is capable of excavating and increased distances projects are requiring.

Open the catalog to page 22

Tunnel Boring Machine - Series II: Interior g

Open the catalog to page 23

Tunnel Boring Machine - Series II: Cutterhead O C Options Dirt cutterhead Carbide (bullet-bit) Cutterhead bar (bullet bit) Sand shelves Cl d face attachment for wet or unstable soils Closed f h f bl il Mixed-ground cutter head

Open the catalog to page 24

TBM Support Equipment: 524 Haul Unit 5 HP-Electric Motor 500 ft per HP Electric Motor-500 minute 36”-60” ID-Typical diameter range Removable battery packminimall d ti i i downtime Ability to use a 60” or 90” long bucket for greater capacity Versatile

Open the catalog to page 25

TBM Support Equipment: 1548 Haul Units 15 HP Min. Min Diameter 60” 60 Adjustable width for use with 20 or 24 gauge track Accommodates 60” or 90” length buckets Front and rear lights Battery charges while braking 750’ per minute

Open the catalog to page 26

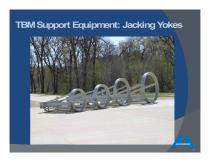

TBM Support Equipment: Jacking Yokes g

Open the catalog to page 27

TBM Support Equipment: Intermediate Jacking S Stations ( S ) (IJS’s)

Open the catalog to page 28

AKKERMAN: Service and Support Akkerman is committed to exceeding customer expectations with integrity integrity, diligence and without compromise. g y Our dedicated and highly knowledgeable team of aftermarket sales and field technical support staff are available f collaboration and il bl for ll b ti d assistance .

Open the catalog to page 29

AKKERMAN Mission Statement Goal driven for customer success

Open the catalog to page 30All Akkerman catalogs and technical brochures

-

GBM 48 Series Jacking Frame

4 Pages

-

P100 Power Pack

2 Pages

-

P150 Power Pack

2 Pages

-

P250D Power Pack

2 Pages

-

P275 Power Pack

2 Pages

-

GBM Guidance System

2 Pages

-

Notched Thrust Casings

2 Pages

-

TBM Series II

2 Pages

-

5000 Series Pump Unit

2 Pages

-

EH2550 Bentonite Pump

2 Pages

-

5000 Series II Pump Unit

2 Pages

-

P400/P600 Power Pack

2 Pages

-

EH2250 Bentonite Pump

2 Pages

-

Akkerman Product Guide

15 Pages

-

1548 Haul Unit

2 Pages

-

524 Haul Unit

2 Pages

-

TBM

2 Pages

-

Control Container

2 Pages

-

Eliminator

2 Pages

-

PCH 36-44"

2 Pages

-

PCH 20-28.5"

2 Pages

-

PRH Kit

2 Pages

-

Jetting and Lubrication Pump

2 Pages

-

P275T Power Pack

2 Pages

-

P150Q Power Pack

2 Pages

-

P100Q Power Pack

2 Pages

-

4812A Jacking Frame

2 Pages

-

308A/339A Jacking Frame

2 Pages

-

240A Jacking Frame

2 Pages

-

EPBM Systems Product Guide

1 Pages

-

Akkerman Product Guide

15 Pages

-

5000 Series Jacking System

1 Pages

-

Tunnel Boring Machine (TBM)

1 Pages

-

Microtunneling

1 Pages

-

Guided Boring Machines (GBM)

52 Pages