Catalog excerpts

Accurate, Small Diameter Pipe Jacking Applications With and Without Pilot Tubes Troy Stokes

Open the catalog to page 1

Guided Boring Machine (GBM) Concept Installing Pipe With the GBM Using Pilot Tube Technology Questions & Answers

Open the catalog to page 2

Privately Held, Family-Owned and Operated Global Sales and Service Full Range of Pipe Jacking and Tunneling Equipment

Open the catalog to page 3

AKKERMAN Guided Boring Machine First GBM Manufactured in 2001 Diameters: 4-48in (102-1220mm) OD Quick Setup Small Footprint Versatile Common Types of Pipe: Clay Concrete Hobas Polycrete Steel Casing

Open the catalog to page 5

Guided Boring Method … What Is It? An extremely accurate method of installing small diameter pipe with the grade and alignment precision required to meet the demands of the sewer, water and utility industry.

Open the catalog to page 6

Displaceable Ground Conditions *** N Value or SPT = < 50 *** Pull Back (PVC, HDPE, etc.) Hybrid: Guidance System for Auger Boring Guidance System for Pipe Ramming Guidance System for HDD

Open the catalog to page 7

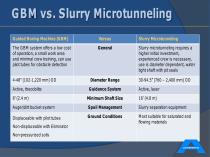

GBM vs. Slurry Microtunneling Guided Boring Machine (GBM) Slurry Microtunneling The GBM system offers a low cost of operation, a small work area and minimal crew training, can use pilot tubes for obstacle detection Slurry microtunneling requires a higher initial investment, experienced crew is necessary, use is diameter dependent, water tight shaft with pit seals Diameter Range Guidance System Active, laser Minimum Shaft Size Auger/dirt bucket system Spoil Management Slurry separation equipment Displaceable with pilot tubes Ground Conditions Most suitable for saturated and flowing materials...

Open the catalog to page 11

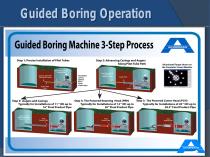

Guided Boring Operation Guided Boring Machine 3-Step Process M Step 1: Precise Installation of Pilot Tubes Step 2: Advancing Casings and Augers Along Pilot Tube Path Illuminated Target shown on the Computer Screen Monitor Step 3: Augers and Casings Step 3: The Powered Reaming Head (PRH) Step 3: The Powered Cutter Head (PCH) Typically for Installations of 11" OD up to Typically for Installations of 14" OD up to Typically for Installations of 20" OD up to 16" Final Product Pipe _ 20" Final Product Pipe M 28.5" Final Product Pipe

Open the catalog to page 12

GBM Guidance System Accuracy = ¼ in @ 300ft (6mm @ 92m)

Open the catalog to page 13

Dual Wall Pilot Tube Lubrication Air / Nitrogen

Open the catalog to page 14

Quick Assembly Long Life Universal Designed for Pull Back

Open the catalog to page 15

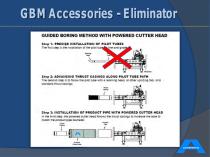

GUIDED BORING METHOD WITH POWERED CUTTER HEAD Step 1: PRECISE INSTALLATION OF PILOT TUBES The firs': step s the Tati'JaSori rf sr« p-a', luoe a** ie ana g-™*e Step 2z ADVANCING THRUST CASINOS ALONG PILOT TUBE PATH The second csep a to '-oCaw tne pilot iutoe mrtn 4 reon* ng heed or attwf jpuirtg 'mi and stniyJond thn,nl eating* Step 3: INSTALLATION OF PRODUCT PIPE WITH POWERED CUTTER HEAD in the ffirfTi ctep. the porttiea t_r:er nead fcAHK he ttvust cac-ngt n - raraue me tore t&

Open the catalog to page 17

The Powered Cutter Head (PCH) is an upsizing tool for a variety of ground conditions PCH Model Frame Type

Open the catalog to page 19

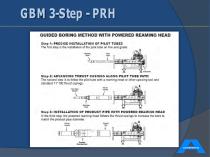

GUIDED BORING METHOD WITH POWERED REAMING HEAD Step 1: PRECISE INSTALLATION OF PILOT TUBES The f*sl step is the- installation of the p::ot tube on lire, and grade Step 2: ADVANCING THRUST CASINGS ALONG PILOT TUBE PATH The second slep is 10 SC+IDW the pilot tjbe with a ream4ig head or other upsizing tool and standard 1 V QDihrusf. casingp. Step 3: INSTALLATION OF PRODUCT PIPE WITH POWERED REAM IMG HEAD In the third step, the powered reaming head fallows the thrust casings to increase the bore to match the product pipe d aniEter.

Open the catalog to page 21

Powered Reaming Head (PRH) Kit = 14 / 16 / 20” (350 / 400 / 500 mm) OD Install Multiple Diameters With One Kit

Open the catalog to page 22

Designed for Non-Displaceable Soils Bullet Teeth Hollow Augers Works With All Sizes of GBM Jacking Frames

Open the catalog to page 24

GUIDED BORING METHOD WITH POWERED CUTTER HEAD Step 1: PRECISE INSTALLATION OF PJLOT TUBES The firs': step s the ^la a^on of tiepka! m Step £ ADVANCING THRUST CASINOS ALONG PILOT TUBE PATH The second crep s to Inflow tne p-toi h/be inra reon* r>ead Df -other upwuig looi. arid stn-ntjard thjuss casings. Slep 3: INSTALLATION OF PRODUCT PIPE WITH POWERED CUTTER HEAD \TI the th*u step, the powered C^TST wad to. orvs lw thru-si casings u -nc^Me tne tors ta motefi the product p pe d^i™tr.

Open the catalog to page 25

Akkerman GBM Jacking Frames offer unmatched versatility and advanced engineering GBM Model Frame Type

Open the catalog to page 26

Every jacking frame needs hydraulic power, Akkerman Power Packs provide the right match Pump Unit Model Power Level

Open the catalog to page 27

Guidance For Auger Boring Machines

Open the catalog to page 28

Why Should I Guide My Auger Rig? Improved Accuracy Longer Drives Possible Smaller Faster Bullet Teeth Casing Sizes Less Find Dewatering Obstacles Before They Find You!

Open the catalog to page 29

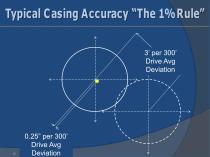

Typical Casing Accuracy “The 1% Rule” 3’ per 300’ Drive Avg Deviation

Open the catalog to page 30

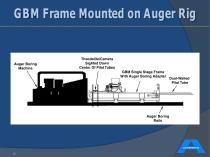

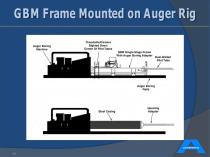

GBM Frame Mounted on Auger Rig

Open the catalog to page 31

Auger Boring Sighted Down Machine Center Of Pilot Tubes Auger Boring

Open the catalog to page 32

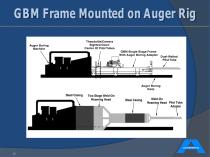

GBM Frame Mounted on Auger Rig

Open the catalog to page 33

GBM Frame Mounted on Auger Ri Auger Boring Sighted Down Center Of Pilot Tubes GBM Single Stage Frame With Auger Boring Adapter Pilot Tube Auger Boring Steel Casing

Open the catalog to page 34

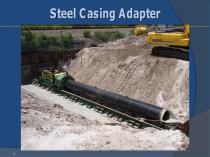

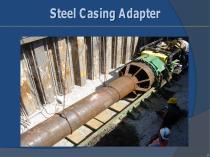

Steel Casing Adapter

Open the catalog to page 35

GBM Frame Mounted on Auger Ri Auger Boring Sighted Down Center Of Pilot Tubes GBM Single Stage Frame With Auger Boring Adapter Dua|.Wa||ed Pilot Tube Auger Boring Steel Casing Two Stage Weld-On k \ Reaming Head steel Casing ^ Weld-On Reaming Head Pilot Tube

Open the catalog to page 36

Steel Casing Adapter

Open the catalog to page 37

GBM Accessories – Auger Boring Weld-On Reaming Head Adapters Pilot Tube Swivel

Open the catalog to page 38

Service and Support Akkerman is committed to exceeding customer expectations with integrity, diligence and without compromise Our dedicated and highly knowledgeable team of aftermarket sales and field technical support staff are available for collaboration and assistance

Open the catalog to page 39

“At Akkerman, Right is Right!”

Open the catalog to page 40All Akkerman catalogs and technical brochures

-

GBM 48 Series Jacking Frame

4 Pages

-

P100 Power Pack

2 Pages

-

P150 Power Pack

2 Pages

-

P250D Power Pack

2 Pages

-

P275 Power Pack

2 Pages

-

GBM Guidance System

2 Pages

-

Notched Thrust Casings

2 Pages

-

TBM Series II

2 Pages

-

5000 Series Pump Unit

2 Pages

-

EH2550 Bentonite Pump

2 Pages

-

5000 Series II Pump Unit

2 Pages

-

P400/P600 Power Pack

2 Pages

-

EH2250 Bentonite Pump

2 Pages

-

Akkerman Product Guide

15 Pages

-

1548 Haul Unit

2 Pages

-

524 Haul Unit

2 Pages

-

TBM

2 Pages

-

Control Container

2 Pages

-

Eliminator

2 Pages

-

PCH 36-44"

2 Pages

-

PCH 20-28.5"

2 Pages

-

PRH Kit

2 Pages

-

Jetting and Lubrication Pump

2 Pages

-

P275T Power Pack

2 Pages

-

P150Q Power Pack

2 Pages

-

P100Q Power Pack

2 Pages

-

4812A Jacking Frame

2 Pages

-

308A/339A Jacking Frame

2 Pages

-

240A Jacking Frame

2 Pages

-

EPBM Systems Product Guide

1 Pages

-

Akkerman Product Guide

15 Pages

-

5000 Series Jacking System

1 Pages

-

Tunnel Boring Machine (TBM)

1 Pages

-

Microtunneling

1 Pages

-

Guided Boring Machines (GBM)

52 Pages