Catalog excerpts

Compressors Manufacturing Company Ltd. SCREW COMPRESSORS

Open the catalog to page 1

Airpol – SCREW COMPRESSORS Microprocessor Controller The screw compressors are ready for operation and fully automatic units designed for continuous operation in harsh operating conditions. Easy to read display and user friendly user menu enables an effective control and supervision of the compressor or compressor group operation. The units are made in the sound-proof housing in a version with or without air receiver. They are equipped with the belt drive or direct drive. All compressors are manufactured in accordance with the standards and requirements specified in the directives...

Open the catalog to page 2

SCREW COMPRESSORS WITH BELT DRIVE SIMPLE DESIGN, EASY TO USE DIRECT DRIVE SCREW COMPRESSORS motor power from 3 kW to 55 kW motor power from 30 kW to 315 kW HIGHEFFICIENCY DRIVE Effective cooling system Suitably selected air coolers with the carefully thought out air flow system enable the compressors to operate at ambient temperature up to 400C and ensure appropriate compressed air cooling. The most efficient drive option, where the screw unit is coupled directly to an electric motor, using the flexible coupling. Owing to such a solution, there are no energy losses when a torque is...

Open the catalog to page 3

SCREW COMPRESSORS WITH COMPRESSED AIR TREATMENT SYSTEM Compact design The refrigerant dryer together with two compressed air filters are located in one housing with the entire compressor. It eliminates the necessity of providing an additional operating space and spending installation costs of the compressed air treatment system. Airpol KT Airpol T The compact design equipment dedicated to the users who have a small working area and are looking for an efficient compressor station with increased cleanliness class. Good access to components The elements to be maintained and serviced are...

Open the catalog to page 4

SCREW COMPRESSORS WITH FREQUENCY INVERTER Airpol PR Airpol KPR Airpol PRT Airpol KTPR with motor power from 5,5 kW to 315 kW Infinite rotation adjustment and constant pressure in the compressed air network The Airpol PR series compressors have infinite rotation adjustment from 50% to 100%, (in special versions of screw compressors - from 20% to 100%). If air consumption is lower than 50% of the maximum compressor capacity, a signal that stops the machine is sent from the frequency inverter. The operation control system with the frequency inverter tries to maintain the compressor motor...

Open the catalog to page 5

The Airpol Power Control controllers, based on the modern technologies (microprocessor with the Cortex core), meet the recent industrial requirements with simultaneous minimum power consumption and correct, failure-free compressor operation. Easy to read display, information diodes and clear keyboard provide easy and fast configuration of operating parameters, diagnosis of the compressor operation state, as well as an operation mode selection. EASY USE AND CLEAR WAY OF PARAMETER CHANGES ECONOMIC WAY OF THE COMPRESSOR OPERATION CONTROL THE LEDS ON THE CONTROLLER INFORM THE OPERATING...

Open the catalog to page 6

HEAT RECOVERY FROM SCREW COMPRESSORS HEATING ENERGY SAVING Every screw compressor converts 100% of the supplied electrical energy into heat energy. Only 4% of heat energy remains in the compressed air, and 96% may be effectively recovered and used again. Water/oil exchanger Approx. 78% of energy may be recovered by installation of the water/oil exchanger in the compressor. Heated water is used in the water central heating system or domestic hot water system. The plate heat exchanger system is anticipated for standard applications. The use of thin plates, effective use of heat exchange...

Open the catalog to page 7

CONTAINER COMPRESSOR STATIONS OPERATION PRINCIPLE OF SCREW COMPRESSORS The container compressor stations are used wherever there is a need for the source of compressed air or nitrogen and there is no possibility of building a compressor room. They provide high mobility and use at any location by a user. Ambient air is sucked through the filter 1 and then it flows through the suction regulator equipped with the variable control valve adapting to instantaneous demand for compressed air. The suction regulator operation is controlled by the electrical unit connected to the pressure Oil...

Open the catalog to page 8

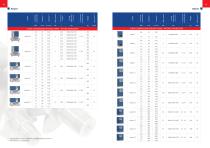

Noise level **) Motor power *) Capacity measured acc. to EN ISO 1217:2006 and EN ISO 5167-2. **) Noise level acc. to EN ISO 2151. SCREW COMPRESSORS WITH BELT DRIVE – WITHOUT AIR RECEIVER SCREW COMPRESSORS WITH BELT DRIVE – ON THE AIR RECEIVER 0,8 Discharge overpressure Noise level **) Motor power Discharge overpressure

Open the catalog to page 9

SCREW COMPRESSORS WITH DIRECT DRIVE 1:1 0,75 Airpol NB 30 Noise level **) Motor power *) Capacity measured acc. to EN ISO 1217:2006 and EN ISO 5167-2. **) Noise level acc. to EN ISO 2151. 15 SCREW COMPRESSORS WITH AIR DRYER AND COMPRESSED AIR FILTERS – ON THE AIR RECEIVER Discharge overpressure Noise level **) Motor power Discharge overpressure In screw compressors Airpol KT and Airpol T series: - pressure dew point of the refrigeration air dryer: +30C - 2.4.2 compressed air quality class, acc. to ISO 8573.1 (in standard version of screw compressors KT and T).

Open the catalog to page 10

SCREW COMPRESSORS WITH FREQUENCY CONVERTER – ON THE AIR RECEIVER G 3/4 Noise level **) SCREW COMPRESSORS WITH AIR DRYER AND COMPRESSED AIR FILTERS – WITHOUT AIR RECEIVER Motor power Discharge overpressure Noise level **) Motor power Discharge overpressure

Open the catalog to page 11

Noise level **) SCREW COMPRESSORS WITH FREQUENCY CONVERTER – WITHOUT AIR RECEIVER Motor power Discharge overpressure

Open the catalog to page 12

SCREW COMPRESSORS WITH FREQUENCY CONVERTER AND AIR DRYER – ON THE AIR RECEIVER *) Capacity measured acc. to EN ISO 1217:2006 and EN ISO 5167-2. **) Noise level acc. to EN ISO 2151. In screw compressors Airpol KTPR and Airpol PRT series: - pressure dew point of the refrigeration air dryer: +30C - 2.4.2 compressed air quality class, acc. to ISO 8573.1 (in standard version of screw compressors KTPR and PRT). SCREW COMPRESSORS WITH FREQUENCY CONVERTER AND AIR DRYER – WITHOUT AIR RECEIVER Noise level **) Motor power Discharge overpressure Noise level **) Motor power Discharge overpressure

Open the catalog to page 13All Airpol catalogs and technical brochures

-

Airpol screw air ends

2 Pages

-

air treatment system

12 Pages

-

scroll compressor

8 Pages

-

Airpol screw compressor

6 Pages

Archived catalogs

-

Boosters Catalogue

8 Pages

-

Screw compressor catalogue

24 Pages