Catalog excerpts

ExpanTek' Tube Expansion Systems and Tooling ExpanTek® Model TH Ball Expansion System ■ Pressures up to 10,000 psi (689 bar) ■ Hydro-mechanical ball straight line tube expansion ■ Cycle times as fast as 3 seconds ■ Single or dual operator work stations ■ Manufactured to customer specifications The ExpanTek® Model TH Ball Expansion System is designed specifically for hydro-mechanical straight line tube expansion applications. The components and circuitry in this system will provide reliable, repeatable expansion of tubes. The triplex hydro ball process uses water pressure to force a ball through the inside of the tube, thus expanding the tube to a desired diameter. The ExpanTek® Model TH Ball Expansion System, when used with the Model 22 Series Ball Expansion Tool, provides a safe, efficient means for straight line tube expansion for boiler tube liners, condenser coils, evaporator coils, and fin/tube bonding. CONSTRUCTION Frame: Aluminum frame with steel panels mounted on a steel skid platform 38.5 in. x 51.8 in. x 57.1 in. (977.9 mm 1315.7 mm 1450.3 mm) Single or dual operator work stations Corrosion-resistant materials Stainless steel or brass Work Stations: Triplex Pump: Valves and Fittings: The Model TH Ball Expansion System is powered by a three-phase electric motor, and uses a belt-driven triplex pump to provide water pressures up to 10,000 psi (689 bar). The operator interface includes all necessary controls and gauges to adjust and monitor system function. The system is mounted on a skid platform, so it can be moved with a forklift to different manufacturing cells. OPERATION The ExpanTek® Model TH Ball Expansion System when used with the Airmo Model 22 Series Ball Expansion Tool is easy to operate. Simply verify there is a ball in the tube prior to attaching the tool, then push the tool straight onto the tube. Next, initiate the pressure cycle by actuating the electrically operated foot switch. The system automatically forces the ball down the entire length of the tube, mechanically expanding it. Typical expansion cycles are 3 to 5 seconds, depending on tube size and length. Ball expansion tools can be quickly changed over using quick disconnect couplings. Fluid Piping: Heavy wall stainless steel and rubber hoses Gauges/Transducers: Stainless steel construction SYSTEM CONFIGURATION Maximum Water Pressure: Up to 10,000 psi (689 bar) Maximum Water Flow: Up to 4 gpm (15.1 lpm) Motor Power Output: Up to 25 HP Electrical: Tailored to electrical service OPERATING CONDITIONS Temperature: 32° F to 120° F (0° C to 49° C) Services: Water or other fluids Cycle Time: 3 seconds for small volume tubes Noise Level: Pump and motor run quietly

Open the catalog to page 1

MAXIMUM PRESSURE Ball Expansion System BASIC SYSTEM The Model TH Ball Expansion System basic system is configured as follows: Triplex piston pump, with pressure outputs to 10,000 psi (689 bar) Electric motor, with power capability to 25 HP Control system, operated with low voltage foot switch Precision regulator, supplies water pump giving operator greater control of pressure Safety valve, prevents water pressure from exceeding maximum Analog gauges, high accuracy and durability for monitoring output water pressure Strainer and water filter, reduce contaminants for better...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

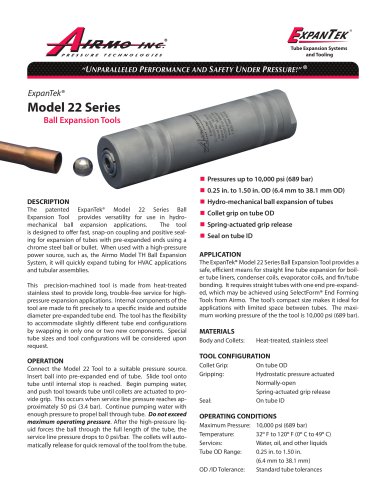

Model 22 Series

2 Pages

-

Model M Series

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 Series

2 Pages

-

Model 400 HPU

2 Pages

-

Model 525 Series

2 Pages

-

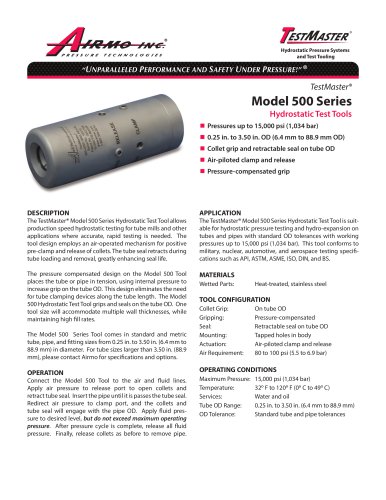

Model 500 Series

2 Pages

-

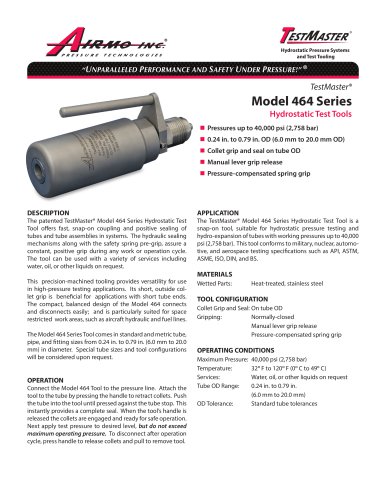

Model 464 Series

2 Pages

-

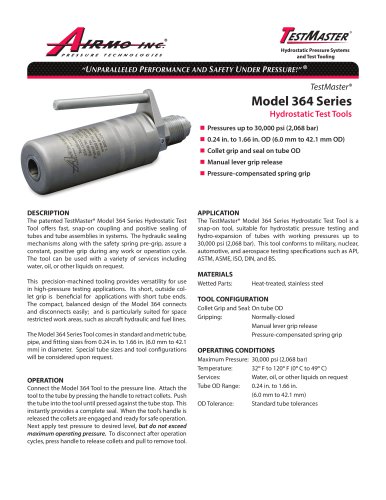

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

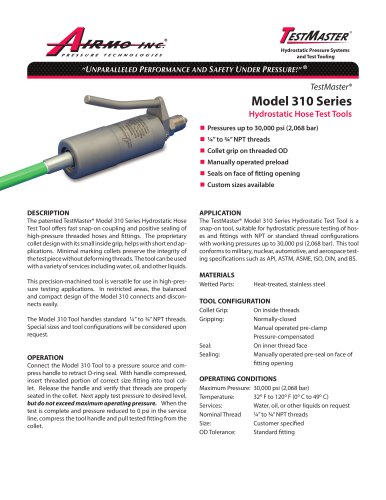

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

300 Series

2 Pages

-

LPH Series

2 Pages

-

30096HT

2 Pages

-

Model HPS

2 Pages