Catalog excerpts

SfLECrFORM End Forming Systems and Tooling "UNPARALLELED PERFORMANCE AND SAFETY UNDER PRESSURE!"® Model M Series Modular End Forming Tools ■ Pressures up to 3,000 psi (207 bar) ■ 0.13 in. to 3.00 in. OD (3.2 mm to 76.2 mm OD) ■ Expand, reduce, bead, or flare tube ends ■ Modular tools in three sizes: ram or finger style ■ Precision-machined stainless steel construction ■ Manufactured to customer specifications Collet Grip: Actuation: Forming Type: Expansion Length: Expansion: Reduction Length: Reduction: Bead: Flare: DESCRIPTION The patented SelectForm® Model M Series Modular End Forming Tool accurately expands, reduces, beads, or flares a shape on tube ends with diameters from 0.13 in. to 3.00 in. (3.2 mm to 76.2 mm). These tools are available in three sizes and designed to be easily interchangeable modules and tooling. When combined with the SelectForm® Model 400 Hydraulic Power Unit, tools can be mounted as a single-station or multistation configuration on top of the power source. Modular Tooling Breakdown: The modular tooling consists of two major components: the gripping and the forming modules. Mounted within each of these modules are individual sets of tooling, which can be quickly converted to different tube diameters or produce different forms. Gripping Module: The gripping module contains a set of collets, which grips and holds the tube during the forming process. One set of collets is required for each outside tube diameter to be formed. The form shape can also affect collet requirements. For example, the collet for producing 0.63 in. (15.9 mm) beads is different from the collet for 0.63 in. (15.9 mm) flares. Forming Modules: Two forming modules are available, each with a convenient knob to control form length. The expansion module produces an expanded tube end or bell shape. The reduction module is used to produce reductions, flares, and beads. Mounted within each of these modules is a set of forming tooling. One set of tooling is required for each specific form size and shape you expect to produce. APPLICATION The SelectForm® Model M Series End Forming Tools produce a variety of tube end forms used by industrial manufacturers in aerospace, boiler manufacturing, heat exchanger and radiator, military, nuclear and hydro-electric, metal furniture, outdoor power equipment, plumbing fittings, sports equipment, boat and water craft, tube and pipe mills. MATERIALS Materials: Aluminum, carbon steel, copper, stainless steel, TOOL CONFIGURATION On tube OD Hydraulically-operated extend and retract Hydraulic ram for most applications Finger style for beading in sizes 2 and 3 only Up to 3 x tube OD, depending on application <20% of the Tube OD* (material varies range) Up to 3 x tube OD, depending on application <20% of the Tube OD* (material varies range) AS5131 or other specification 37° and 45° OPERATING CONDITIONS Maximum Pressure: 3,000 (207 bar) Temperature: 32° F to 120° F (0° C to 49° C) Cycle Time: 7 seconds

Open the catalog to page 1

MAXIMUM PRESSURE Model M Series Modular End Forming Tools Model M Series Modular End Forming Tools COMMON END FORMS * Note: Usable formed length is less than stroke. FEATURES ■ Fast operation, cycles in 7 seconds or less ■ Choice of 3 modular sizes in ram or finger style ■ Fast tool changeover ■ Low marking collet design ■ Adjustable form length control ■ Compact design ■ Precision-machined from heat-treated stainless steel ■ Coated mandrels and dies ■ Non-standard sizes ■ Designed for use with SelectForm® Hydraulic Power Unit BENEFITS Increases productivity and throughput Tube diameters...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

Model 22 Series

2 Pages

-

Model TH

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 Series

2 Pages

-

Model 400 HPU

2 Pages

-

Model 525 Series

2 Pages

-

Model 500 Series

2 Pages

-

Model 464 Series

2 Pages

-

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

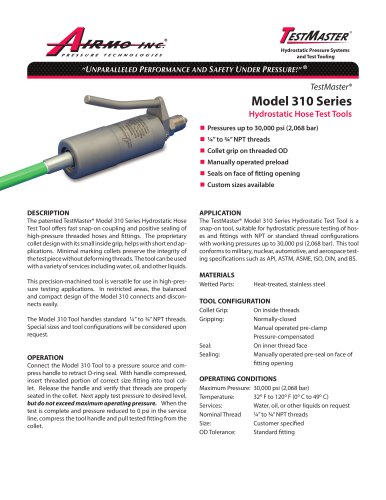

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

300 Series

2 Pages

-

LPH Series

2 Pages

-

30096HT

2 Pages

-

Model HPS

2 Pages