Catalog excerpts

"UNPARALLELED PERFORMANCE AND SAFETY UNDER PRESSURE!"® TestMaster® Model 525 Series Hydrostatic Test Tools ■ Pressures up to 15,000 psi (1,034 bar) ■ 0.25 in. to 6.63 in. OD (6.4 mm to 168.4 mm OD) ■ Collet grip and retractable seal on tube OD ■ Air-piloted clamp and release ■ Pressure-compensated grip DESCRIPTION The TestMaster® Model 525 Series Hydrostatic Test Tool allows production speed hydrostatic testing for tube mills and other applications where accurate, rapid testing is needed. The tool design employs an air-operated mechanism for positive preclamp and release of collets. Its tube seal retracts during tube loading and removal, greatly enhancing the seal life. APPLICATION The TestMaster® Model 525 Series Hydrostatic Test Tool is suitable for hydrostatic pressure testing and hydro-expansion on tubes and pipes with standard OD tolerances with working pressures up to 15,000 psi (1,034 bar). This tool conforms to military, nuclear, automotive, and aerospace testing specifications such as API, ASTM, ASME, ISO, DIN, and BS. The pressure compensated design on the Model 525 Tool places the tube or pipe in tension, using internal pressure to increase grip on the tube OD. This design eliminates tube clamping devices along the tube length. One tool size will accommodate multiple wall thicknesses, while maintaining high fill rates. The Model 525 Series Tool handles standard and metric tube, pipe, and fitting sizes from 0.25 in. to 6.63 in. (6.4 mm to 168.4 mm) in diameter. Special tube sizes and tool configurations will be considered upon request. MATERIALS Wetted Parts: Heat-treated, stainless steel TOOL CONFIGURATION Collet Grip: Gripping: Seal: Mounting: Actuation: Air Requirement: On tube OD Pressure-compensated Retractable seal on tube OD Tapped holes in body Air-piloted clamp and release 80 - 100 psi (5.5 - 6.9 bar) Maximum Pressure: Temperature: Services: Tube OD Range: OD Tolerance: OPERATION Connect the Model 525 Tool to the air and fluid lines. Apply air pressure to release port to open collets and retract tube seal. Insert the pipe either manually or automatically in a system until it is passes the tube seal. Redirect air pressure to clamp port, and the collets and tube seal will engage with the pipe OD. Apply fluid pressure to desired level, but do not exceed maximum operating pressure. After pressure cycle is complete, release all fluid pressure. Finally, release collets as before to remove pipe.

Open the catalog to page 1

MAXIMUM PRESSURE Hydrostatic Test Tools Full-flow, high pre fill rate Air-actuated collet release Patented retractable seal design and segmented collets Built-in tube end tolerances require no square cut ends Pressure-compensated design Tube size sets allow rapid changeover between tube sizes Low marking collet design Precision-machined from heat-treated stainless steel Compatible with NuQuip® Automatic Air-Bleed Valve Decreases cycle time Ensures fast, easy chuck removal Quick connection to plain end or upset tube or pipe Lowers machining costs Contains all high-pressure...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

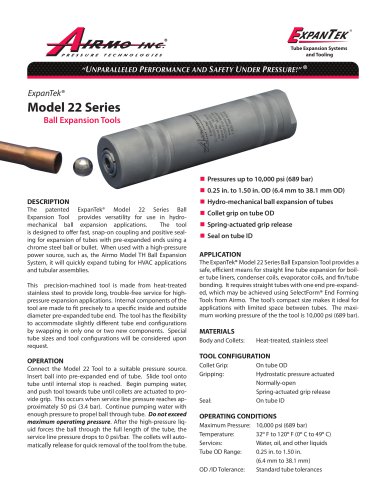

Model 22 Series

2 Pages

-

Model TH

2 Pages

-

Model M Series

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 Series

2 Pages

-

Model 400 HPU

2 Pages

-

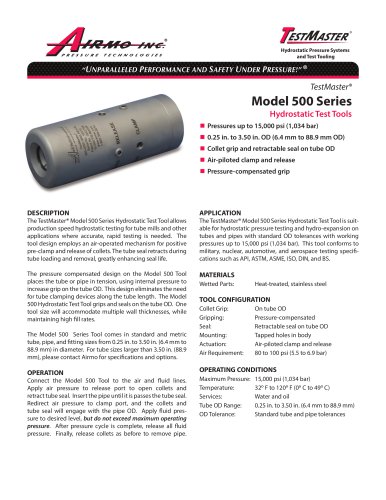

Model 500 Series

2 Pages

-

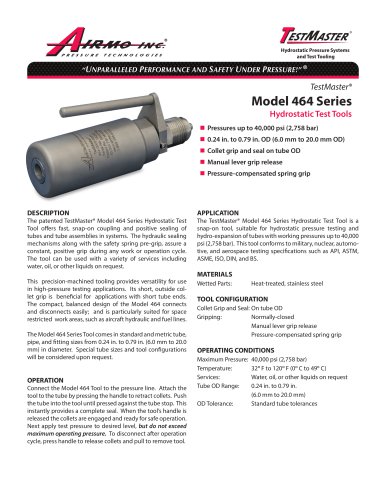

Model 464 Series

2 Pages

-

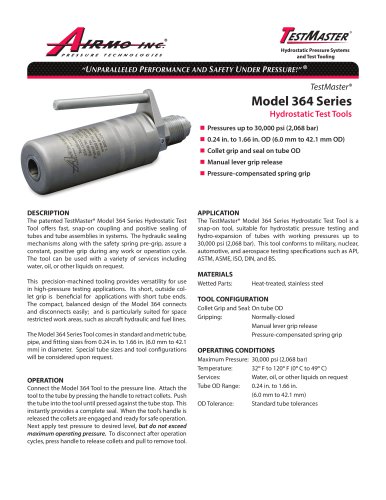

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

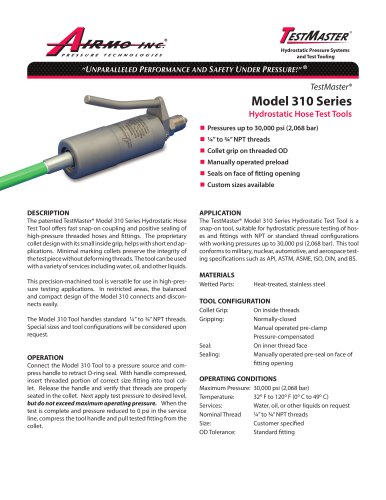

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

300 Series

2 Pages

-

LPH Series

2 Pages

-

30096HT

2 Pages

-

Model HPS

2 Pages