Catalog excerpts

'UNPARALLELED PERFORMANCE AND SAFETY UNDER PRESSURE!"® SelectForm® Model 400 Series End Forming Tools ■ Pressures up to 3,000 psi (207 bar) ■ 0.19 in. to 1.38 in. OD (4.7 mm to 35.0 mm OD) ■ Pressure-compensated design ■ Expand, reduce, bead, or flare tube ends ■ Precision-machined stainless steel construction The patented SelectForm® Model 400 Series End Forming Tool is a dedicated, hand-held tool that accurately expands, reduces, beads, or flares a single shape on the end of tube diameters from 0.19 in. to 1.38 in. (4.7 mm to 35.0 mm). These tools utilize two quick disconnects for easy connection to hydraulic power unit. When combined with the SelectForm® Model 400 Hydraulic Power Unit, the tool is simply placed over the tube end and the operator presses a foot switch on the power source. The tool cycles automatically, producing a finished form in 2 to 5 seconds. The SelectForm® Model 400 Series End Forming Tools are used to produce a specific end form on tubes for manufacturing applications in a variety of industries, including: aerospace and aircraft, boiler, heat exchanger and radiator, military, nuclear and hydro-electric, metal furniture, on/off road mobile vehicles, outdoor power equipment, plumbing fittings, sports equipment, boat and water craft, tube and pipe manufacturing. TOOL CONFIGURATION Actuation: Hydraulically-operated extend and retract OPERATING CONDITIONS Maximum Pressure: 3,000 (207 bar) MODEL 400 DEDICATED END FORMING TOOLS Temperature: Tube OD Range: Expansion Length: Expansion: Reduction Length: Reduction: Flare: Wall Thickness: Materials: 32° F to 120° F (0° C to 49° C) 0.19 in. to 1.38 in. (4.7 mm to 35.0 mm) Up to 3 x tube OD, depending on application <20% of the Tube OD* Up to 3 x tube OD, depending on application <20% of the Tube OD* 37° and 45° Standard tubing Aluminum, carbon steel, copper, stainless steel, and titanium Actual expansion range may vary depending on material, please check with Airmo for details.

Open the catalog to page 1

MAXIMUM PRESSURE End Form - aluminum, carbon steel, copper, stainless steel, and titanium Model 400 Tool - Expansion Model 401 Tool - Ball Inserter Model 403 Tool - Bead Model 402 Tool - Reduction Model 437 Tool - Flare Special Configurations Available Upon Request Fast operation, cycles in 2 to 5 seconds Pressure-compensated design Low marking collet design Compact, balanced design Precision-machined from heat-treated stainless steel Low maintenance Designed for use with SelectForm® Hydraulic Power Unit Increases productivity and throughput Contains all high-pressure loads...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

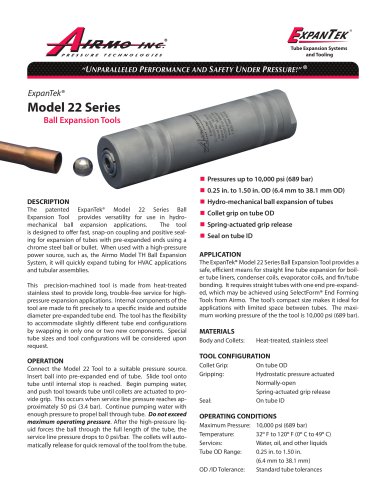

Model 22 Series

2 Pages

-

Model TH

2 Pages

-

Model M Series

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 HPU

2 Pages

-

Model 525 Series

2 Pages

-

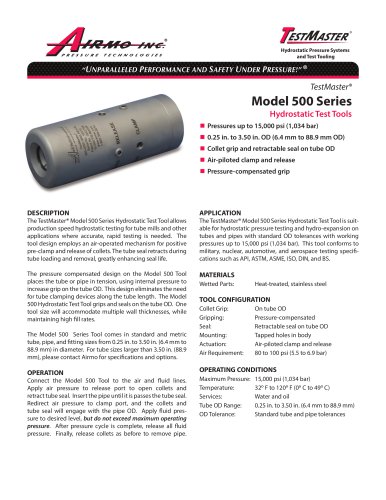

Model 500 Series

2 Pages

-

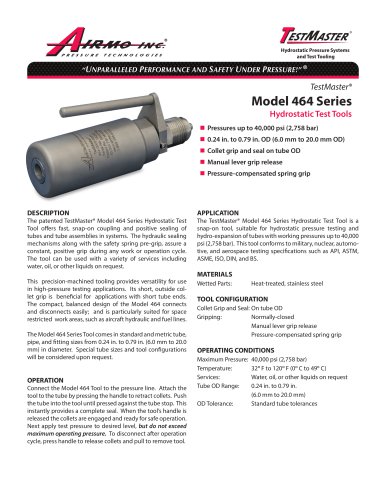

Model 464 Series

2 Pages

-

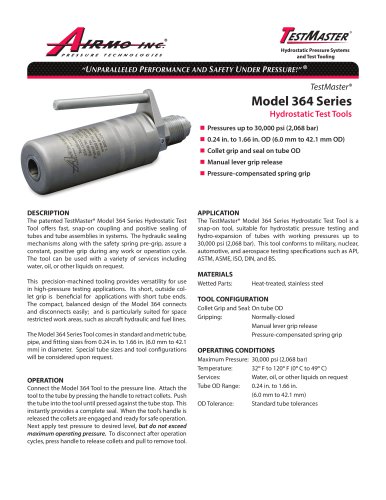

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

300 Series

2 Pages

-

LPH Series

2 Pages

-

30096HT

2 Pages

-

Model HPS

2 Pages