Catalog excerpts

ExpanTek Tube Expansion Systems and Tooling "UNPARALLELED PERFORMANCE AND SAFETY UNDER PRESSURE!"® ExpanTek® Model 22 Series Ball Expansion Tools DESCRIPTION The patented ExpanTek® Model 22 Series Ball Expansion Tool provides versatility for use in hydro mechanical ball expansion applications. The tool is designed to offer fast, snap-on coupling and positive sealing for expansion of tubes with pre-expanded ends using a chrome steel ball or bullet. When used with a high-pressure power source, such as, the Airmo Model TH Ball Expansion System, it will quickly expand tubing for HVAC applications and tubular assemblies. This precision-machined tool is made from heat-treated stainless steel to provide long, trouble-free service for high-pressure expansion applications. Internal components of the tool are made to fit precisely to a specific inside and outside diameter pre-expanded tube end. The tool has the flexibility to accommodate slightly different tube end configurations by swapping in only one or two new components. Special tube sizes and tool configurations will be considered upon request. ■ Hydro-mechanical ball expansion of tubes ■ Collet grip on tube OD ■ Spring-actuated grip release ■ Seal on tube ID APPLICATION The ExpanTek® Model 22 Series Ball Expansion Tool provides a safe, efficient means for straight line tube expansion for boiler tube liners, condenser coils, evaporator coils, and fin/tube bonding. It requires straight tubes with one end pre-expanded, which may be achieved using SelectForm® End Forming Tools from Airmo. The tool's compact size makes it ideal for applications with limited space between tubes. The maximum working pressure of the the tool is 10,000 psi (689 bar). MATERIALS Body and Collets: Heat-treated, stainless steel OPERATION Connect the Model 22 Tool to a suitable pressure source. Insert ball into pre-expanded end of tube. Slide tool onto tube until internal stop is reached. Begin pumping water, and push tool towards tube until collets are actuated to provide grip. This occurs when service line pressure reaches approximately 50 psi (3.4 bar). Continue pumping water with enough pressure to propel ball through tube. Do not exceed maximum operatimg pressure. After the high-pressure liquid forces the ball through the full length of the tube, the service line pressure drops to 0 psi/bar. The collets will automatically release for quick removal of the tool from the tube. TOOL CONFIGURATION Collet Grip: On tube OD Gripping: Hydrostatic pressure actuated Normally-open Spring-actuated grip release Seal: On tube ID OPERATING CONDITIONS Maximum Pressure: Temperature: Services: Tube OD Range: OD /ID Tolerance: 10,000 psi (689 bar) 32° F to 120° F (0° C to 49° C) Water, oil, and other liquids 0.25 in. to 1.50 in. (6.4 mm to 38.1 mm) Standard tube tolerances

Open the catalog to page 1

MAXIMUM PRESSURE Model 22 Series Ball Expansion Tools Model 22 Series Tool Specifications Expanded Tube OD Range* * Note: Tools are designed for a dedicated tube diameter and do not cover the entire diameter range noted at each size. A single tube OD must be specified for the collet set. Special Configurations Available Upon Request FEATURES ■ Large internal passages for high flow ■ Predetermined internal tube stop ■ Automatic collet release ■ Pressure-compensated design ■ Compact, balanced design ■ Precision-machined from heat-treated stainless steel BENEFITS Decreases cycle time Ensures...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

Model TH

2 Pages

-

Model M Series

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 Series

2 Pages

-

Model 400 HPU

2 Pages

-

Model 525 Series

2 Pages

-

Model 500 Series

2 Pages

-

Model 464 Series

2 Pages

-

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

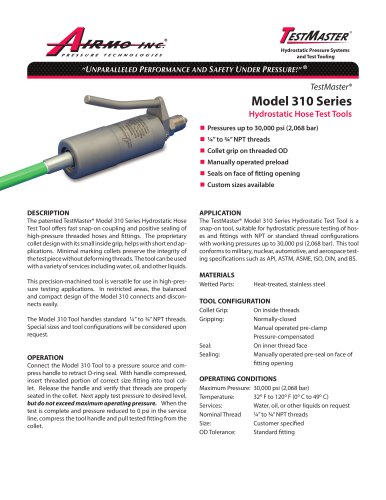

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

300 Series

2 Pages

-

LPH Series

2 Pages

-

30096HT

2 Pages

-

Model HPS

2 Pages