Catalog excerpts

Hydrostatic Pressure Systems and Test Tooling “UNPARALLELED PERFORMANCE AND SAFETY UNDER PRESSURE!” Hydrostatic Burst Test Chamber Pressures up to 30,000 psi (2,068 bar) Non-destructive or destructive test chamber for pressure, leak, burst, and cycle testing Manual, electronic controlled, or fully-automated Typical cycle time from 5 seconds Manufactured to customer specifications The TestMaster® Model 30096HT Hydrostatic Burst Test Chamber is a high-performance source of hydrostatic water pressure used in non-destructive and destructive testing applications. The Burst Test Chamber utilizes a variety of pressure testing methods including hydrostatic testing or air under water testing. At its core is an air-driven water pump, providing up to 30,000 psi (2,068 bar) water pressure when driven by 100 psi (7 bar) air input. The Model 30096HT Burst Test Chamber is designed and manufactured to customer specifications for size, pressure capabilities, and testing requirements. System options include manual control, auto-cycling, PLC control, or PLC touchscreen interface. The stainless steel construction makes this system durable for fully automated, high-volume production line testing. The TestMaster® Model 30096HT Hydrostatic Burst Test Chamber when combined with TestMaster® Hydrostatic Test Tools provide a safe, efficient means of testing products such as tube and hose assemblies, valves, and air conditioning coils. The unit is suitable for testing according to military, nuclear, automotive, and aerospace specifications such as API, ASTM, ASME, ISO, DIN, and BS. Non-Destructive and Destructive Testing Pressure drop testing Leak testing Burst testing Cycle testing Research and development testing CONSTRUCTION Frame: Reservoir Tank: Safety Cover: Air-Driven Pump: Valves and Fittings: Water Piping: Gauges/Transducers: Aluminum extrusion 60 in. x 30 in. x 42 in. (1,524 mm x 762 mm x 1,066 mm) 48 in. x 26 in. x 12 in. (1,219 mm x 660 mm x 304 mm) 0.5 in. (12.7 mm ) high strength polycarbonate; hinged cover Corrosion-resistant materials Stainless steel or brass Heavy wall stainless steel tubing Stainless steel construction SYSTEM CONFIGURATION Maximum Pressure: Accuracy: Maximum Flow: Air Input: Electrical: Control Options: Up to 30,000 psi (2,068 bar) depend- ing on air-driven pump ±50 psi (±3.45 bar) Up to 12 gpm (45.4 lpm) depending on fill pump and air-driven pump Requires 95 psi (7 bar) and 18 SCFM for maximum performance Tailored to electrical service used Manual, auto-cycle, PLC control, PLC touch screen interface OPERATING CONDITIONS Temperature: Services: Cycle Time: Noise Level: 32° F to 120 ° F (0 ° C to 49° C) Water, de-ionized water, oil Typical cycle time from 5 seconds Pumps run quietly, and

Open the catalog to page 1

MAXIMUM PRESSURE Hydrostatic Burst Test Chamber BASIC SYSTEM The Model 30096HT Hydrostatic Burst Test Chamber basic system is configured as follows: Test tank assembly, stainless steel interior for destructive and non-destructive testing. Air-driven water pump, reliable with pressure outputs of 10,000, 20,000, or 30,000 psi; (689, 1,379, 2,068 bar). Precision air regulator, supplies water pump, giving operator greater control of pressure. Analog gauges, high accuracy and durable for incoming and regulated air pressure, and output water pressure. Reservoir, five gallon fill...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

Model 22 Series

2 Pages

-

Model TH

2 Pages

-

Model M Series

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 Series

2 Pages

-

Model 400 HPU

2 Pages

-

Model 525 Series

2 Pages

-

Model 500 Series

2 Pages

-

Model 464 Series

2 Pages

-

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

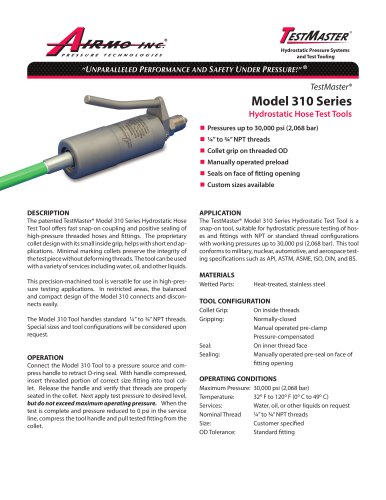

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

300 Series

2 Pages

-

LPH Series

2 Pages

-

Model HPS

2 Pages