Catalog excerpts

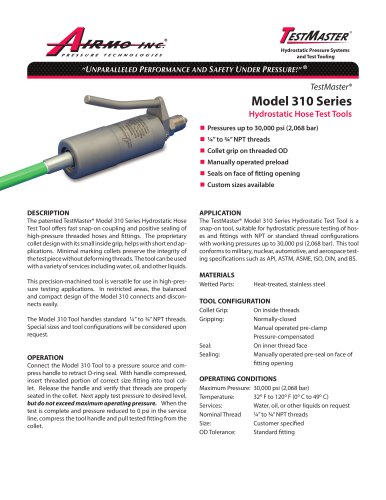

Hydrostatic Pressure Systems and Test Tooling “UNPARALLELED PERFORMANCE AND SAFETY UNDER PRESSURE!” Hydrostatic Test Tools Pressures up to 5,000 psi (345 bar) 0.31 in. to 3.00 in. ID (7.9 mm to 76.2 mm ID) Collet grip and seal on tube ID Air-actuated collet pre-grip and release Pressure-compensated design The patented TestMaster® Model 300 Series Hydrostatic Test Tool offers inside gripping and sealing specially designed for high-pressure hydrostatic and leak testing of tubes swaged into sheets. The hydraulic sealing mechanism along with the safety spring pre-grip, assures a constant, positive grip during any work or operation cycle. The tool can be used with a variety of services including air, water, oil, or other liquids on request. The TestMaster® Model 300 Series Hydrostatic Test Tool is a used in a variety of HVAC production applications including, boiler tube assemblies, shell and tube heat exchangers, boxtype heat exchangers, and other tube assemblies. The Model 300 tool is suitable for applications with working pressures up to 5,000 psi (345 bar). This tool conforms to military, nuclear, automotive, and aerospace testing specifications such as API, ASTM, ASME, ISO, DIN, and BS. The Model 300 Series Tool is suitable for hydrostatic pressure testing up to 5,000 psi (345 bar). The compact, balanced design is particularly suited to restricted work areas with limited space. The Model 300 Series Tool handles standard and metric tube, pipe, and fitting sizes from 0.31 in. to 3.00 in. (7.9 mm to 76.2 mm) in diameter. Special tube sizes and tool configurations will be considered upon request. OPERATION Connect the Model 300 Tool to the test system by attaching one air line to the release port, the other air line to the clamp port, and the hydraulic line to the pressure port. Using suitable valving for manual or automatic testing, apply air pressure of 50 to 90 psi (3.4 to 6.2 bar) to the release port which retracts the collet. Insert tool into tube until pressed against tube stop. Apply air to clamp side. Tool now has positive seal and a grip on the tube. Next apply pressure flow to run test, but do not exceed maximum working pressure. After test is completed the pressure will drop to 0, then apply air pressure to release port and remove the tool from the tube. MATERIALS Wetted Parts: Heat-treated, stainless steel TOOL CONFIGURATION Collet Grip and Seal: On tube OD Gripping: Pressure-compensated Air-Operated: Air-pilot clamp and release Air Requirements: 50 to 90 psi (3.4 to 6.2 bar) OPERATING CONDITIONS Maximum Pressure: 5,000 psi (345 bar) Temperature: 32º F to 120º F (0º C to 49º C) Services: Air, water, oil, or other liquids on request Tube ID Range: 0.31 in. to 3.00 in. (7.9 mm to 76.2 mm) ID Tolerance: Stan

Open the catalog to page 1

MAXIMUM PRESSURE Hydrostatic Test Tools Full-flow, high pre fill rate Predetermined internal tube stops requires no measuring Low marking collet design Special collet design locking principle Lever collet release for fast tool removal Pressure-compensated design Built-in tube end tolerances require no square cut ends Compact, balance design Precision-machined from heat-treated stainless steel Designed for test applications Use with optional NuQuip® Automatic Air-Bleed Valve Decreases cycle time Ensures proper tube depth engagement Prevents tube end collapse and...

Open the catalog to page 2All Airmo Incorporation catalogs and technical brochures

-

Model 22 Series

2 Pages

-

Model TH

2 Pages

-

Model M Series

2 Pages

-

Model 450 Series

2 Pages

-

Model 400 Series

2 Pages

-

Model 400 HPU

2 Pages

-

Model 525 Series

2 Pages

-

Model 500 Series

2 Pages

-

Model 464 Series

2 Pages

-

Model 364 Series

2 Pages

-

Model 350 Series

2 Pages

-

Model 333 Series

2 Pages

-

Model 310 Series

2 Pages

-

Model 264 Series

2 Pages

-

Model 64 Series

2 Pages

-

Model MPG Series

2 Pages

-

Model LPHE Series

2 Pages

-

Catalog 2021

7 Pages

-

LPH Series

2 Pages

-

30096HT

2 Pages

-

Model HPS

2 Pages